Table of contents

Overview of the Custom Crocs Shoes Market in China

- Market Size and Trends

Crocs shoes are popular worldwide for their lightweight comfort and versatile designs. In recent years, the custom Crocs shoes market in China has grown rapidly, especially with the rising demand for personalized products. Consumers increasingly prefer shoes tailored to their style and functional needs, such as color, shoe charms, straps, sole thickness, and printed patterns. - Consumer Demand

Young and trend-conscious users favor unique features like interchangeable charms, glow-in-the-dark soles, and custom prints, while also focusing on comfort, slip resistance, and durability. Brands increasingly prefer small-batch customization and flexible production to quickly respond to changing market trends. - Key Manufacturing Technologies

Manufacturing custom Crocs shoes involves design, 3D modeling, mold development, material selection, injection molding, and post-production finishing. Advanced equipment and automated processes are critical for any crocs shoes manufacturer to deliver high-quality, customized products. Precision in size, comfort, and functionality is essential to meet diverse client requirements.

Overview of the Top 5 Custom Crocs Shoes Manufacturers in China

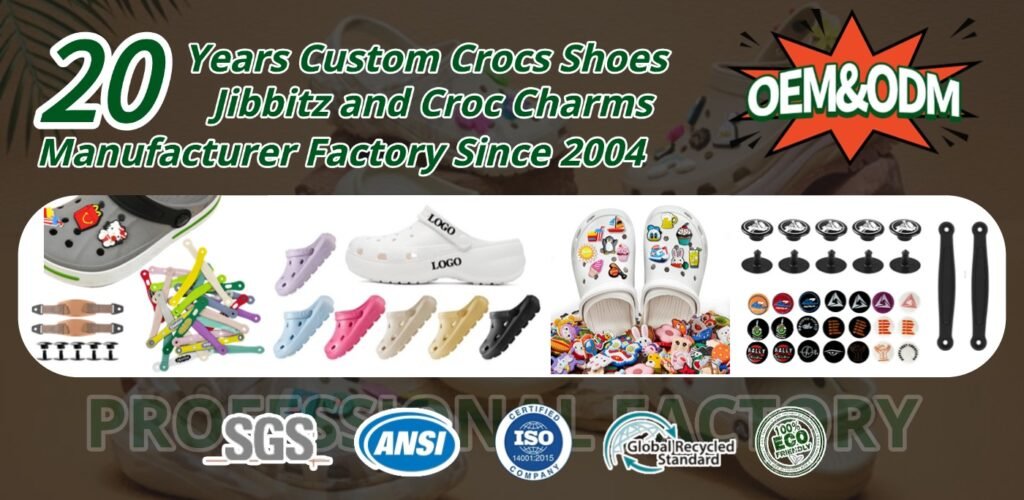

1. Deran: Expert in Custom Crocs Shoes

Established in 2005 in Jinjiang, Fujian, Deran occupies approximately 20,000 square meters with over 200 advanced production machines and an annual capacity exceeding 1 million pairs. Deran specializes in full-range custom Crocs shoes services, including color, charms, straps, sole hardness, and material selection. They support small-batch orders with a minimum order quantity of 200 pairs.

- Technical Advantages

Deran has in-house mold development, ensuring accurate and comfortable shoe shapes. The sampling cycle is short, generally 5–7 days, enabling fast verification of design concepts. - Certifications and Quality

Products are certified with REACH, ROHS, OEKO-TEX, and TUV, meeting international environmental and safety standards. - Client Experience

Deran has long-term collaborations with European and American brands, exporting globally with strict quality management and extensive cross-border customization experience.

2. Xinjia Shoes

Xinjia Shoes is a leading manufacturer in China, specializing in multi-color soles and uppers, offering comprehensive OEM/ODM services to meet small-batch customization needs of brands and retailers.

- Technical Advantages

They can quickly produce prototypes and modifications based on client designs, ensuring design consistency with mass production. - Certifications and Quality

A strict quality management system ensures stable shoe shape, sole hardness, and color consistency, meeting international market requirements. - Client Experience

They have served multiple domestic and international footwear brands, accumulating rich experience in custom Crocs shoes production.

3. Fujian Footwear Tech

Fujian Footwear Tech focuses on lightweight soles and comfort-oriented designs, offering customization for sole hardness, upper materials, and breathability, suitable for sports, leisure, and outdoor scenarios.

- Technical Advantages

Uses eco-friendly, lightweight materials, emphasizing sole compression resistance and cushioning, adjustable per client requirements. - Certifications and Quality

Products comply with international quality and environmental standards, ensuring safe materials and controlled production processes. - Client Experience

They have served domestic and international trendy brands and functional footwear projects, specializing in comfort and functional customization.

4. Jinjiang Trendy Shoes

Jinjiang Trendy Shoes emphasizes fashion design and personalized customization, offering multi-color soles, interchangeable charms, and printed uppers, targeting young and trendy consumers.

- Technical Advantages

Supports rapid prototyping and creative customization, suitable for limited-edition releases. - Certifications and Quality

Strict production controls ensure durable prints, slip-resistant soles, and compliance with environmental standards. - Client Experience

They have cooperated with trend brands and limited-edition projects, accumulating extensive experience in innovative custom Crocs shoes.

5. Huaqiao Shoe Manufacturing

Huaqiao Shoe Manufacturing focuses on high-quality shoe production, suitable for large orders and customized events.

- Technical Advantages

Equipped with advanced injection machines and precise molds to ensure consistent shoe shape and comfort. - Certifications and Quality

Every batch undergoes checks for size, sole hardness, slip resistance, and material safety, meeting international standards. - Client Experience

Provides a one-stop solution from design to delivery, serving large chain brands and custom events, with stable and reliable production capacity.

Customization Process

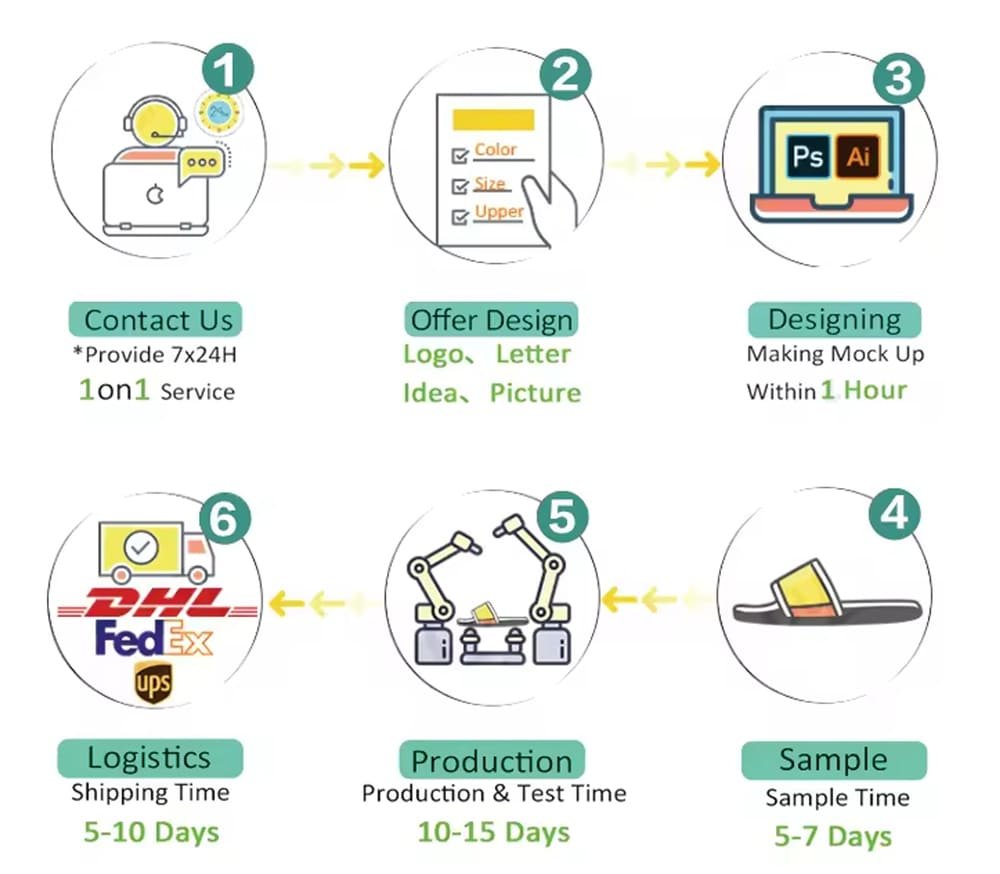

- Design Phase: Clients clarify shoe shape, color, charms, straps, and functional requirements. Crocs shoes manufacturers use 3D modeling software to visualize designs, spot potential issues early, and reduce modification costs.

- Sample Production and Confirmation: Based on the 3D design, prototypes are produced for client review of shape, comfort, material feel, and color. Modifications are made as needed. Sampling typically takes 5–10 days. Once approved, the product moves to mass production.

- Mass Production: Production includes injection molding, assembly, and finishing. Injection machines ensure consistent sole shape and hardness. Assembly integrates the upper, sole, and accessories. Quality checks, including dimension measurement, slip resistance, and material safety testing, ensure every pair meets international standards.

- Packaging and Logistics: Shoes are packed per client specifications, with options for custom boxes or branding. Logistics can be sea, air, or express delivery, with manufacturers providing shipping recommendations to ensure safe, timely delivery of custom Croc shoes.

- Common Issues and Solutions: Typical challenges include color deviation, sizing errors, and high small-batch costs. Using Pantone color references or sample prototypes reduces color discrepancies. Confirming prototype measurements before production avoids sizing issues. Small-batch costs can be reduced by merging orders or sharing molds.

Practical Tips for Working with Custom Crocs Shoes Manufacturers

- Design and Communication Tips: Provide clear design files or illustrations, specifying colors, sole hardness, and charm styles. 3D visualization tools help verify concepts, preventing production errors.

- Production Issue Solutions: Injection defects can be mitigated by experienced manufacturers and controlled temperature and pressure. Material color discrepancies can be checked with pre-production samples. Delivery delays are managed by confirming schedules and maintaining ongoing communication.

- Logistics and Packaging Recommendations: Use individual packaging to avoid scratches during shipping. Overseas clients can choose sea or air transport. Branded packaging enhances perceived value.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

China’s custom Crocs shoes manufacturers offer professional skills, flexible services, and high-quality products, making them trusted partners for global clients. Deran leads with extensive experience and fast prototyping, while other manufacturers excel in material innovation, fashion design, and functional customization. By mastering the customization process, communicating clearly, and monitoring production and logistics, clients can obtain high-quality, comfortable, and personalized custom Croc shoes that meet both market and individual demands.