Table of contents

Deran: Professional Manufacturer of Custom Crocs Shoes

Since 2005, Deran has focused on custom Crocs shoe manufacturing, accumulating 21 years of extensive experience. As a well-known US Crocs manufacturers and Crocs suppliers, Deran leverages years of practical experience and professional skills to provide high-quality custom solutions to global clients.

Deran’s professional advantages in the field of Crocs shoes are mainly reflected in the following aspects:

- Professional Experience and Industry Accumulation: Deran has over twenty years of practical experience in custom Crocs shoes, familiar with the strict requirements of the international market for comfort, durability, and creative design. The company has accumulated rich experience in material selection, production processes, and quality control, providing professional advice to clients and ensuring that each custom Crocs shoe meets international standards.

- Diversified Customization Capability: Deran provides complete OEM/ODM custom services, supporting personalized design for colors, styles, shoe clasps, laces, and brand logos. Whether it is small-batch samples or large-scale production, Deran efficiently turns client ideas into finished products, meeting the diverse needs of businesses and brands of all sizes.

- Environmental Protection and International Standards: In material selection, Deran adheres to eco-friendly materials such as EVA, natural rubber, linen, and bamboo fiber blends, ensuring that each Crocs shoe is comfortable, safe, and environmentally compliant. The company’s Crocs shoes have obtained international certifications including REACH, ROHS, OEKO-TEX, and TUV, providing reliable guarantees for global clients.

- Customer Trust and Industry Reputation: With efficient design response, sample production, and delivery capabilities, Deran has long provided custom services for overseas brands, forming a stable client network. A professional team and high-quality services ensure smooth customer experience and enhance long-term cooperation value.

Deran Custom Crocs Factory’s Professional Strength

Deran possesses strong factory capabilities and a mature production system in custom Crocs shoe manufacturing. Leveraging 21 years of professional experience, the factory provides efficient and reliable custom services for global brand clients. The core advantages of the factory are mainly reflected in the following aspects:

- Flexible OEM/ODM Services: Whether clients want to print their brand logo on Crocs shoes or design unique styles from scratch, Deran can provide complete OEM/ODM solutions. From appearance design and mold development to functional enhancements and shoe accessories, the factory offers mature and feasible plans to ensure every pair of shoes precisely meets client requirements.

- Advanced EVA Foaming and Injection Molding Technology: The core process of Crocs shoes lies in EVA foaming and injection molding. Deran uses fully automated production equipment to achieve one-piece shoe body molding, ensuring lightness, comfort, and durability. Additionally, the factory supports dual-color injection molding, achieving multi-color or gradient effects to follow fashion trends. Customizable anti-slip sole textures further enhance shoe functionality and provide superior wearing experience.

- Strict Environmental and International Certifications: For the stringent environmental regulations of the European and American markets, all raw materials used by Deran have passed international certifications such as REACH, ROHS, OEKO-TEX, and TUV. Products are non-toxic, recyclable, and eco-friendly, eliminating export risks from the source and providing reliable assurance for clients.

- Rapid Prototyping and Flexible Production: Deran offers rapid prototyping, with samples completed in as fast as 7 days. The factory supports flexible minimum order quantities, ranging from hundreds to millions of pairs. Normal delivery cycles for large orders are 25–45 days, helping clients seize market opportunities promptly.

- High Production Capacity and Team Support: Deran’s factory is equipped with 4 production lines, with a monthly capacity of 400,000 pairs of Crocs shoes. Experienced R&D and technical teams combined with efficient business support ensure smooth processes from design communication and sample production to mass manufacturing.

- Strict Quality Control System: The factory has an independent quality inspection department that conducts multiple tests on each batch: bending and tensile tests ensure wear resistance and crack resistance; anti-slip tests meet ASTM and EU standards; antibacterial and deodorizing treatments enhance user experience.

Deran’s Custom Crocs Shoe Service Advantages

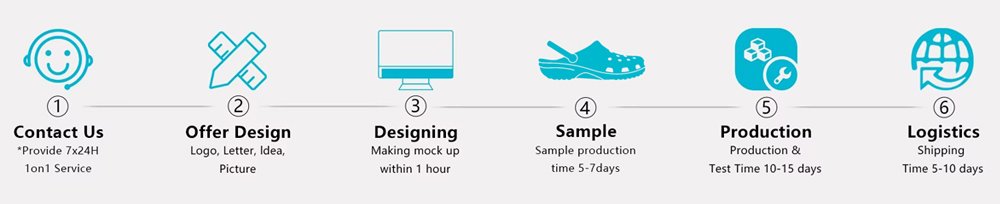

Deran has significant advantages in Crocs shoe customization, covering the full process of design, production, prototyping, logistics, and after-sales service, providing clients with professional, flexible, and efficient custom experiences. The main service advantages include:

1. Diversified Customization Options

Deran provides a variety of customization schemes to meet the personalized needs of different brands and companies. Customizable items include:

- Color Selection: Single-color, dual-color, or gradient options based on client brand colors or market trends.

- Shoe Body Design: Supports different shoe shapes, upper materials, and creative designs.

- Shoe Clasps and Laces: Offers diverse clasp and lace colors and materials for personalized matching.

- Brand Logo and Pattern Printing: Logos, text, images, or creative patterns can be printed on the shoe surface, sole, or laces.

- Functional Customization: Such as anti-slip sole textures, comfort adjustments, antibacterial and deodorizing treatments.

2. Small-Batch Rapid Prototyping

Deran supports small-batch customization with a minimum order of only 200 pairs of Crocs shoes, ideal for startups or clients testing the market. Sample production usually takes 5–7 days, helping clients quickly verify design and quality.

3. Strict Quality Control Process

From raw material inspection to production and final product testing, every step undergoes strict quality checks. Tests include wear resistance, bending, comfort, anti-slip performance, and compliance with environmental standards, ensuring each Crocs shoe meets international standards.

4. Fast Production and Efficient Delivery

Deran’s factory has 4 production lines with a monthly capacity of 400,000 pairs of Crocs shoes, flexibly arranging production. Single-batch production can be completed in 12–24 hours. The production cycle for formal orders is generally 10–15 days for manufacturing plus 5–10 days for logistics, helping clients quickly capture market opportunities.

5. Professional Client Support and After-Sales Service

Provides 7×24-hour one-on-one online support, responding promptly to client needs in design, sampling, production, and logistics. Efficient communication and service processes ensure clients enjoy a worry-free customization experience, enhancing long-term cooperation value.

Deran’s Successful Cases and Client Feedback

Deran has long cooperated with overseas brands, accumulating rich client cases and a good reputation. The following are some successful practices:

- Corporate Gift Customization: Providing multiple international companies with branded Crocs shoe customization, printing company logos and specific patterns for employee benefits and event gifts. Order quantities range from hundreds to thousands of pairs. Deran can complete sample production in 7 days and quickly adjust color, shoe shape, and functional design according to client needs, ensuring large-scale production is delivered on time and meets corporate event and promotional needs.

- Retail and E-commerce Collaboration: Supports brand retailers in small-batch creative Crocs shoe customization, helping them quickly test market response and achieve rapid iteration. Some startup e-commerce brands order only 200–500 pairs; Deran provides flexible production and rapid prototyping support, enabling clients to optimize designs timely and launch to the market, reducing inventory pressure and risk.

- Event and Exhibition Customization: Provides personalized Crocs shoe customization for various exhibitions and themed events, enhancing brand exposure and customer engagement. For example, a cooperation at an international exhibition involved 1,500 pairs of themed Crocs shoes; Deran provided full-process support from design advice and sample production to mass production, ensuring perfect product presentation during the event and enhancing brand impact and engagement on-site.

Client feedback shows that Deran responds quickly to designs, produces samples promptly, and maintains stable product quality. Whether small-batch samples or large-scale production, Deran can deliver on time and flexibly meet client needs. With 21 years of Crocs shoe customization experience, 4 efficient production lines, and the use of eco-friendly materials, Deran has earned the trust of global clients and is a long-term reliable crocs suppliers and crocs manufacturers.

Reasons to Choose Deran: Authority and Long-Term Cooperation Value

Deran’s advantages lie not only in strong production capabilities but also in long-standing industry reputation, reliable service, and strict quality standards. Choosing Deran means selecting a trusted crocs suppliers and crocs manufacturers for long-term collaboration. Key reasons include:

- Stable Supply Chain: With 21 years of Crocs shoe customization experience, Deran has established long-term partnerships with upstream material suppliers to ensure stable raw material supply. Whether EVA, natural rubber, or linen and bamboo fiber blends, the factory guarantees consistent quality to meet the high standards of global markets.

- International Collaboration and Production Capacity Guarantee: Deran has long-term cooperation with numerous international sports brands and retail chains, with quarterly shipments reaching millions of pairs. The efficient 4 production lines and a complete production management system enable the factory to flexibly handle large orders and ensure on-time delivery, meeting brand market rhythms.

- Strict Environmental and International Certification: Deran adheres to green production principles; all materials are recyclable, and production complies with international environmental standards. The factory’s Crocs shoes are certified by REACH, ROHS, OEKO-TEX, and TUV, ensuring non-toxic, eco-friendly products that meet European and American export requirements, providing reliable assurance for clients in international markets.

- Customer Reputation and Long-Term Cooperation Value: On platforms such as Alibaba International, Deran has received consistent praise from global clients. Customers generally acknowledge that Deran responds quickly to designs, produces samples promptly, maintains stable quality, and can flexibly adjust production plans according to market demands, providing attentive after-sales service. Long-term partners include startups and large retailers, reflecting the factory’s authority and reliability in Crocs shoe customization.

With a stable supply chain, international certifications, extensive collaboration experience, and strong reputation, Deran provides clients not only Crocs shoe products but also efficient, reliable, and long-term sustainable cooperation value.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

With 21 years of accumulated experience, a complete production system, rich customization services, and global client recognition, Deran has become a trusted Crocs manufacturers and crocs suppliers. Whether for corporate gifts, retail brands, or exhibition event customization, Deran provides one-stop solutions from design, sample production, manufacturing, to delivery.

Choosing Deran is not only choosing high-quality Crocs shoe products but also selecting a reliable, flexible, and sustainable partner to help brands achieve rapid growth and long-term value in the global market.