Table of contents

- Deran’s Manufacturing Strength: The Foundation of a Top Jibbitz Manufacturer

- Inside Deran Factory: Complete Jibbitz Manufacturing Process from Design to Mass Production

- Deran’s Customization Capabilities: Meeting Brand Personalization Needs

- Core Materials and Technologies Used by Deran: The Science Behind High-Quality Jibbitz

- How to Collaborate with Deran for Jibbitz Charms Wholesale

Deran’s Manufacturing Strength: The Foundation of a Top Jibbitz Manufacturer

Deran was established in 2005 and has been dedicated to manufacturing clogs, flip-flops, plush slippers, shoe charms, and Crocs accessories for 20 years. As a professional jibbitz manufacturer, Deran has long provided high-quality OEM, ODM, and wholesale services for brand clients and independent sellers.

Factory Scale and Production Capacity

- Factory area: 4,000 square meters of modern production facilities

- Production lines: 4 complete production lines

- Monthly capacity: 400,000 pairs of slippers, 1 million Crocs charms

- Mold workshop: Independently operated, supporting fast mold making and sample testing

Experience and Professionalism

With 20 years of experience in footwear and shoe accessory manufacturing, Deran combines mature processes with high production efficiency to ensure each product meets market standards. The factory is equipped with an experienced engineering team with over 10 years in shoe accessory design, capable of customizing functions and structures to ensure products are both aesthetically pleasing and practical.

International Certifications and Quality Assurance

Deran’s products have passed international safety and environmental certifications such as REACH, ROHS, EN71, and CPSIA, ensuring non-toxic, odorless, and skin-friendly products, especially suitable for children’s markets, gift markets, and high-safety scenarios. Strict quality control covers incoming materials, in-process sampling, and final product inspection, including tensile testing, colorfastness testing, and environmental compliance tracking, ensuring traceable and reliable product quality.

Inside Deran Factory: Complete Jibbitz Manufacturing Process from Design to Mass Production

Understanding Deran’s production process helps reveal the professionalism and rigor behind high-quality Jibbitz products. The process—from design, mold making, and material selection to mass production—is strictly controlled.

- Design Development: Deran uses AI-assisted design software, Rhino, and ZBrush for 3D modeling, allowing designers to accurately present complex patterns before production. Designs including cartoon characters, animal shapes, logos, and holiday themes can all be highly reproduced.

- Mold Manufacturing and Analysis: The factory has an independent mold workshop using CNC machining and mold flow analysis. Scientific mold design and precise control of injection parameters ensure stable dimensions, uniform thickness, and minimal defects.

- Material Mixing and Injection Molding: Deran selects environmentally friendly materials such as PVC, TPU, and TPR, strictly controlling ratios and temperatures to ensure consistent color, stable shape, and good hand feel for each batch.

- Surface Processing and Finishing: The factory provides multiple surface treatments including silk screen printing, pad printing, UV coating, and epoxy resin to enhance wear resistance, color saturation, and tactile quality, making each Jibbitz product both durable and visually appealing.

- Assembly, Trimming, and Quality Inspection: Molded charms are hand-trimmed to remove burrs and excess material, followed by hardness, wear, and adhesion tests to ensure each product meets quality standards.

- Packaging Process: Deran offers diverse packaging options based on client needs, including bulk, OPP bags, card packaging, or gift box sets. Packaging protects the product while meeting retail display requirements.

Through systematic management and rigorous quality control, Deran ensures every jibbitz charms wholesale product meets high-quality and reliability standards.

Deran’s Customization Capabilities: Meeting Brand Personalization Needs

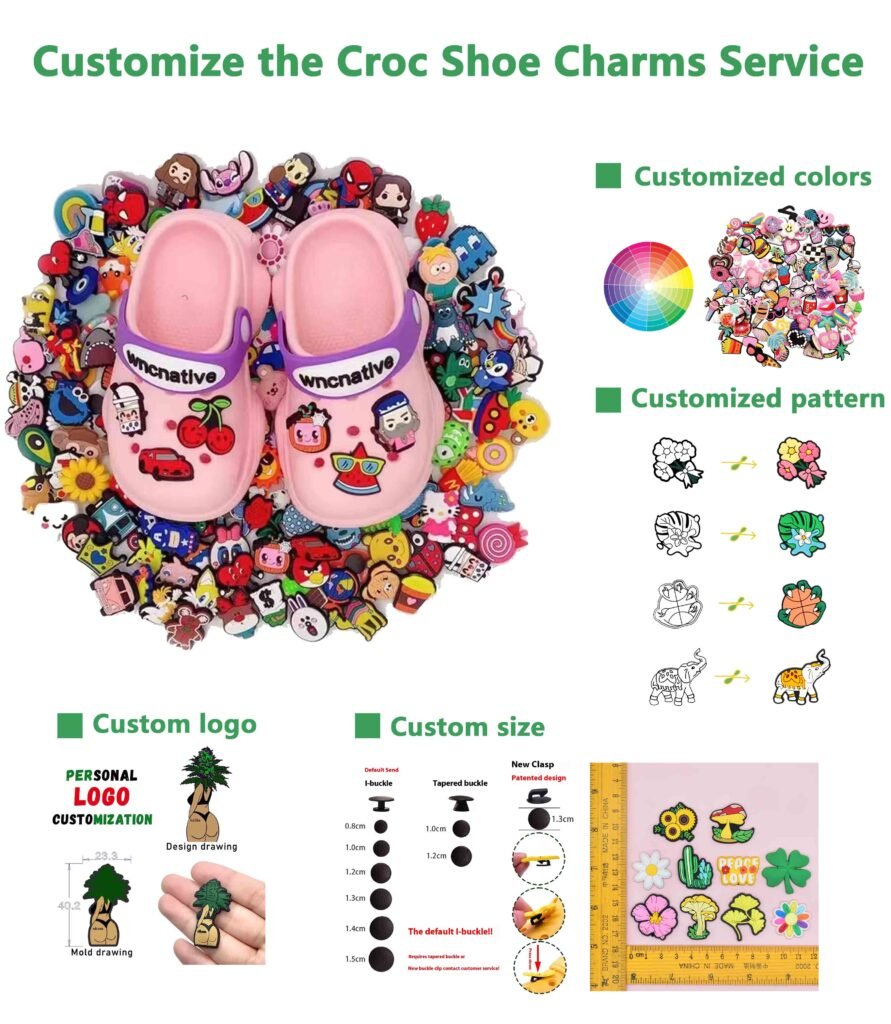

In the Crocs accessories field, personalization is key to brand competitiveness. Deran has mature OEM and ODM customization processes, efficiently turning client creative ideas into finished products. Whether for cross-border e-commerce sellers, brand owners, or gift companies, Deran provides flexible, fast, and high-quality solutions.

- Crocs Charms and Shoe Charm Customization: Deran supports 2D flat and 3D designs, producing cartoon characters, animal shapes, logos, and holiday-themed patterns. Color accuracy is high, strictly following PANTONE standards to ensure each product matches the design exactly.

- Crocs Shoe Charm Customization: Multiple structural forms are available, including insert, rotation, and buckle types, ensuring charms are firm and not easy to detach. Functional designs, such as LED lights and spinning structures, are also supported, adding creativity and interactivity.

- Crocs Heel Strap Customization: Deran can customize heel strap color, length, pattern, and logo printing. Materials include TPU, silicone, and PP, meeting the size requirements for both children’s and adult shoes. Flexible customization allows brands to create unique and practical accessory lines.

- Rapid Sampling and Mold Design: Deran has a dedicated mold design team managing the entire process from sketch modeling, 3D printing, to mold production. Sampling cycles take as little as 7–10 days, with samples provided for client confirmation, ensuring final mass production matches expectations.

Through this systematic customization service, Deran helps brands achieve a one-stop solution from concept to finished product, making every pair of Crocs shoes uniquely personalized and market-competitive.

Core Materials and Technologies Used by Deran: The Science Behind High-Quality Jibbitz

High-quality Jibbitz products rely on scientific management of materials and processes.

Material Characteristics

- PVC: Durable, highly moldable, suitable for complex patterns

- TPU: Soft, scratch-resistant, suitable for flexible charms

- TPR: Combines elasticity and durability, ideal for charm attachment

Environmental Material Application

- Products comply with REACH, ROHS, EN71, CPSIA standards

- Use of recyclable and eco-friendly materials reduces environmental impact

- Provides material reports and sustainable packaging recommendations

Color and Hardness Control

- Spectrophotometers monitor color consistency (ΔE <1.0)

- Shore A hardness optimized for charm flexibility and durability

Advanced Equipment and Technology

- Injection machines precisely control temperature, pressure, and flow

- UV coating and epoxy systems improve wear resistance and gloss

- Laser cutting enables precise processing of complex shapes

Scientific management of materials and technology ensures every jibbitz manufacturer product is visually appealing, durable, and safe.

How to Collaborate with Deran for Jibbitz Charms Wholesale

Collaborating with Deran allows brands and retailers to access a one-stop solution from design and sampling to mass production, achieving efficient wholesale and customization. Deran’s mature production system and professional team provide flexible and reliable services tailored to client needs.

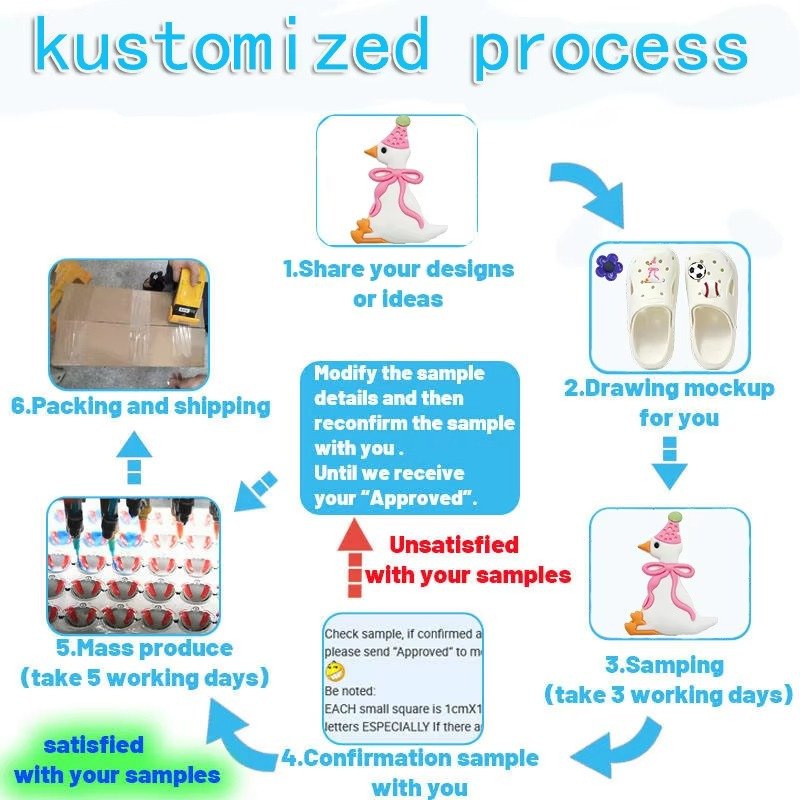

Collaboration Process

- Requirement Communication: Clients provide design concepts, product specifications, quantity, and customization requirements. Deran’s professional team offers feasibility advice to ensure smooth production.

- Design and Sampling: The factory conducts 2D or 3D modeling according to requirements. Sampling takes 7–10 days, and client confirmation precedes mass production to ensure the final product matches expectations.

- Mass Production and Quality Control: Each batch undergoes strict inspection for size, color, adhesion, and environmental compliance, ensuring international standards are met.

- Packaging and Logistics: Various packaging options are available, including bulk, OPP bags, card packaging, or gift boxes. Labels, logos, and shipping packaging are customized per client requirements to ensure safe delivery.

Minimum Order and Wholesale Advantages

- Crocs charms minimum order: 500 pieces

- Crocs shoes minimum order: 200 pairs

- Supports small-batch rapid customization as well as large-batch long-term supply

- Efficient production and strict quality control ensure stable, high-quality product supply

Customization Support and Technical Guidance

Deran provides expert material selection advice, including TPU, PVC, TPR, silicone, and PP, ensuring products are both aesthetic and durable. For functional features (LED lights, spinning structures, shoe charm types), Deran’s engineering team offers feasibility evaluation and optimization, reducing production risk and increasing market competitiveness.

Through systematic collaboration and technical support, Deran helps brands quickly launch personalized, high-quality jibbitz charms wholesale products, achieving differentiated sales and brand value.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Choosing the right jibbitz manufacturer is key to ensuring product quality, customer satisfaction, and brand value. Deran, with 20 years of manufacturing experience, advanced equipment, professional customization capabilities, eco-friendly material use, and global supply experience, provides an efficient and reliable one-stop solution for brands, retailers, and wholesalers.

From Crocs charms, shoe charms, to straps and accessories, Deran transforms creative ideas into high-quality, safe, and eco-friendly products, helping clients create unique and story-filled fashion footwear.

Whether you are a startup brand, cross-border e-commerce seller, or gift company, Deran is a trustworthy partner, turning every pair of Crocs into a personalized and quality-assured footwear experience.