Table of contents

Deran’s Core Advantages as a Leading Crocs Charms Supplier

As a croc shoe charms wholesale factory-based company with a long history of manufacturing Crocs shoes, Birkenstocks, and footwear accessories, Deran already possessed a mature foundation in footwear material processing, mold design capabilities, and a large-scale manufacturing system before entering the Crocs charms market. This gives Deran a natural advantage in charms products, with three key advantages:

- Understanding shoe material structure and wearing scenarios

- Familiarity with international footwear quality and safety standards

- Experience in developing highly complex molds

Based on this foundation, Deran has systematically developed its charms business, gradually building the following six core competencies.

A true factory-based supplier, not just a trading integrator

In the Crocs charms market, one of the most common problems buyers encounter is:

👉 What appears to be a factory quote actually involves multiple layers of outsourcing, leading to fluctuating quality, uncontrollable delivery times, and blurred lines of responsibility.

Deran’s advantages lie in:

- Mold design, injection molding, coloring, assembly, and packaging are all completed in their own factory.

- They possess independent material formulation adjustment capabilities, rather than simply using generic market materials.

- They have a complete QC team and testing processes, not just random sampling.

What does this mean?

When a brand needs to upgrade the feel of materials, enhance wear resistance, improve color saturation, shorten delivery times, or adjust structural adaptability, Deran can directly complete the engineering adjustments internally, instead of going through layers of communication and repeated trial and error.

Strong Customization Capabilities, Not Just “Logo Changes”

Many charm suppliers’ so-called “customization” is essentially just:

- Changing patterns on existing molds

- Or sticking a logo on an existing shape

Deran’s customization capabilities cover:

- Customized Exterior Structure: 3D IP shapes, multi-layered assembly structures, irregular embossed structures

- Customized Material Structure: Multiple combinations of PVC, TPR, silicone, EVA, and composite elastomers

- Customized Color Systems: Precise Pantone color matching, gradient effects, multi-color splicing

- Customized Functional Structure: Glow-in-the-dark, scented, flexible, detachable, and rotating structures

- Customized Packaging Systems: Individual blister packs, eco-friendly paper cards, IP co-branded boxes, retail sets

This means Deran is not just an “OEM,” but a manufacturing partner that can participate in the brand’s product definition phase.

Fast Mold Development, Short Sample Cycle

In charm customization, mold development is often a critical juncture for project success or failure. In traditional processes, mold production cycles typically require:

- 15–25 days for design and manufacturing

- 5–7 days for trial molding and adjustments

- 7–10 days for sample production and verification

The total cycle easily exceeds 30–40 days.

Deran significantly reduces this cycle through its internal engineering team, standardized mold module library, and digital modeling system:

- Standard charms project mold cycle: 7–12 days

- First sample confirmation cycle: 3–5 days

- Mass production switchover cycle: Completed within 3 days

This is a crucial competitive advantage for clients requiring rapid new product launches, limited-time IP collaborations, and e-commerce bestseller testing.

Detailed Steps for Production and Customization

Once the design direction is clear, the next step is transforming ideas into actual products. A professional production process ensures quality and efficiency.

1. Design Sketch and Digital Modeling

- Hand-drawn sketches: Present the overall shape, size proportion, and pattern layout.

- 3D modeling: Complex designs can be modeled digitally with software like Blender or SolidWorks, facilitating mold making and precise production.

2. Sample Production and Color Proofing

- Initial samples must be checked for size, color, and material accuracy.

- Sample production usually takes 7–10 days. Confirmed samples ensure smooth bulk production and reduce costs from later modifications.

- High color accuracy follows the PANTONE standard to guarantee consistency with the original design.

3. Bulk Production Considerations

- Collaborate with reliable jibbitz wholesale suppliers to ensure mold precision and material stability.

- Conduct small-batch trial production to verify hole placement, color, and structural integrity.

- Control production temperature, pressure, and cooling time to avoid deformation, air bubbles, or uneven color.

Following these steps ensures every stage from design to finished product is precise and efficient, balancing creativity and practicality.

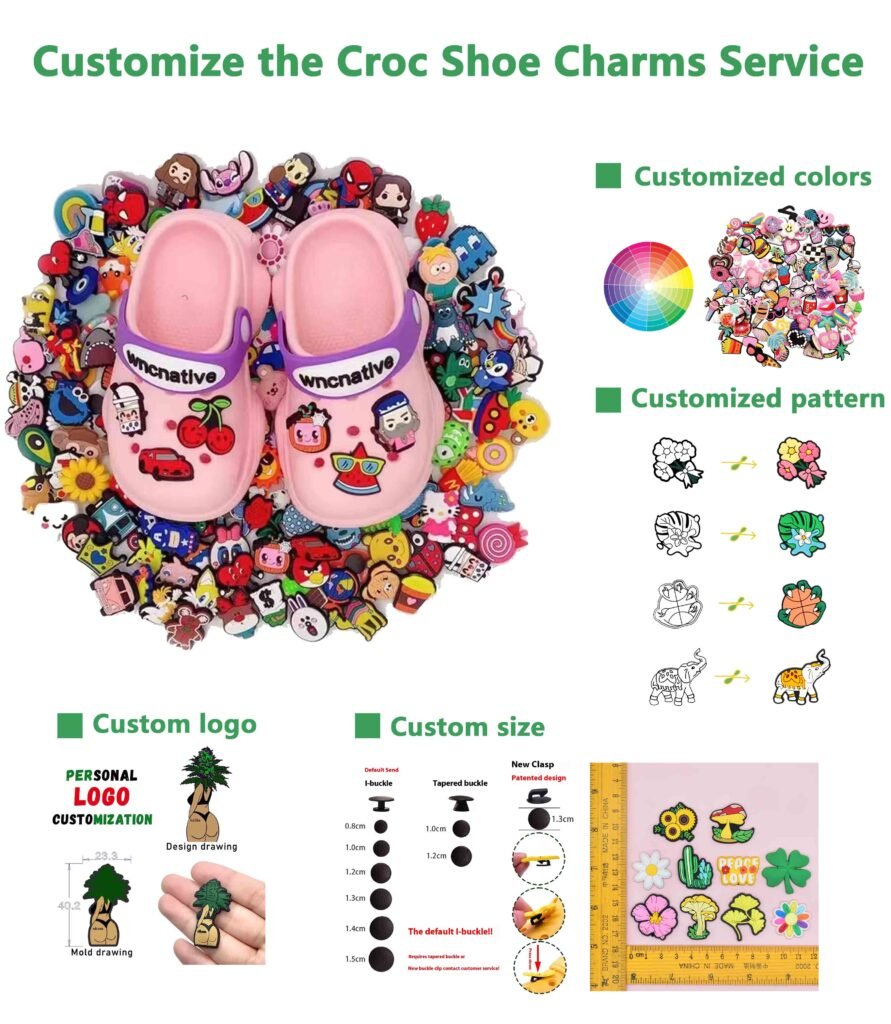

Deran’s Custom Services

In the field of Crocs charms and shoe decorations, personalization is key. Since 2005, Deran has accumulated 20 years of manufacturing experience, offering OEM and ODM services to brand clients, cross-border e-commerce sellers, and gift companies. We transform your creative ideas into high-quality Crocs shoe charms efficiently while providing flexible and fast production solutions.

1. Crocs Shoe Charms/Charms Customization

- Supports 2D flat and 3D designs, including cartoon characters, animal shapes, brand logos, and holiday-themed patterns.

- Color accuracy follows the PANTONE standard to ensure the final product matches the design.

- Dimensions, thickness, and hole placement can be customized to ensure comfort and stability when worn.

2. Crocs Shoe Buckle Customization

- Offers various structural types, including insert, rotating, and clip-on designs, ensuring durability and stability.

- Supports functional designs such as LED lights and rotating mechanisms to meet creative and special requirements.

- Materials include silicone, TPU, PVC, and soft rubber, balancing texture and durability.

3. Crocs Heel Strap Customization

- Customize colors, lengths, patterns, and brand logos to fit both children’s and adult sizes.

- Materials include TPU, silicone, and PP, ensuring comfort and durability.

- Supports laser engraving, screen printing, and heat-pressed logos to enhance product recognition and aesthetics.

Through these professional customization services, Deran helps clients achieve full-process personalized production from design to bulk manufacturing and packaging. Whether it’s Jibbitz charms, shoe decorations, or heel strap accessories, we provide a one-stop solution to make every pair of Crocs uniquely stylish and high-quality.

Deran’s Custom Production Advantages

- Rich Experience and Professional Skills: Deran has over 20 years of experience in slippers and shoe charms production, with an engineering team holding more than 10 years of experience in accessory design. We customize functionality and structure according to client needs to ensure aesthetic and practical value.

- High-Precision Molds and Fast Production: The factory has independent production workshops that support high-precision molds and rapid prototyping, ensuring consistent quality during mass production.

- Efficient Production Capacity: Deran’s factory covers 4,000 square meters with 4 modern production lines. Monthly output reaches 400,000 slippers or 1,000,000 Crocs shoe charms, meeting small-batch custom orders and large-scale commercial demands.

- Strict Quality Control: From raw material intake to final product shipment, Deran implements full-process quality control, including sampling, tensile tests, colorfastness checks, and environmental compliance tracking. All Crocs accessories pass REACH, ROHS, EN71, CPSIA certifications, ensuring non-toxic, skin-friendly, and child-safe products.

- Personalized and Flexible Customization: Deran supports a wide range of customization options including color, pattern, material, and special functionality. Whether small-batch personalized orders or mass production, we provide one-stop service from design to bulk production and packaging.

Case Studies: From Customization to Practical Application

- Children’s Anime-Themed Charms: For the children’s market, Deran designed anime-themed charms made of high-elastic silicone. They are water-resistant and impact-resistant. The charms are cute, brightly colored, and suitable for birthday parties, holidays, and outdoor activities, ensuring safety and fun.

- Adult Personalized Text Charms: For adult customers, Deran provides PVC text charms that can be customized with names, phrases, or brand logos. Lightweight and comfortable, they coordinate with the shoe body, ideal for daily wear or social display, giving each pair a unique personality.

- Multi-Functional Detachable Charms: Deran offers detachable, replaceable charms that can also serve as keychains or small decorative accessories. The structure is sturdy, easy to remove and replace, without affecting shoe comfort, meeting user needs for personalized styling and creative display.

- Holiday-Themed Series Charms: Deran customizes charms for various holidays or themed events, including Christmas, Halloween, and summer beach themes. Each charm is vividly colored, creatively designed, sturdy, and comfortable, ideal for gift markets and seasonal sales.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Customizing Crocs shoe charms is not only a fashion statement but also a reflection of personal creativity. Clarifying design style and functional requirements, strictly controlling production processes, and working with professional croc shoe charms wholesale or wholesale croc charm vendors ensures your creative ideas are realized successfully.

Deran is the ideal partner for brand clients, independent sellers, and gift companies. Whether it’s Jibbitz charms, shoelaces, or complete Crocs accessory solutions, Deran offers one-stop services from design to delivery. Turn every pair of Crocs into a stylish, story-filled footwear piece—start customizing your exclusive shoe charms today!