Table of contents

The Rise of the Custom Slide Shoe Market in the United States

Over the past decade, the role of slide shoes in the U.S. market has changed significantly. What began as basic footwear mainly used for bathrooms and home wear has gradually evolved into an important shoe category covering leisure, sports, outdoor use, brand merchandise, and commercial scenarios. This shift has not been driven solely by fashion trends, but by multiple market forces working together.

- A shift in consumer habits toward “comfort first”: U.S. consumers are increasingly prioritizing long-term wearing comfort over appearance alone. With their easy slip-on design, simple structure, and comfortable foot feel, slide shoes are widely used in high-frequency scenarios such as working from home, short outings, gyms, and vacations, leading to steadily increasing repurchase rates.

- A significant increase in brand demand for customization: Compared with traditional athletic or functional footwear, slide shoes offer greater flexibility in color, material, upper structure, and brand presentation. More and more brands are choosing custom slide shoes to quickly test the market, create potential bestsellers, or use them as branded merchandise, thereby reducing development costs and inventory risks.

- Small-batch, multi-cycle purchasing becoming the mainstream model: In the U.S. market, e-commerce brands, retailers, and startups increasingly favor a supply chain model of “low minimum order quantity + fast replenishment.” This trend has directly driven demand for custom slide manufacturers, as suppliers that can support flexible MOQs and stable delivery gain a clear competitive advantage.

- Continuous expansion of cross-industry application scenarios: Slide shoe buyers are no longer limited to traditional footwear brands. They now include hotel groups, fitness chains, clubs, corporate gift channels, and event customization markets. These customers tend to focus more on delivery time, consistent quality, and brand presentation, making them highly reliant on manufacturers with OEM / ODM capabilities.

Driven by these trends, the U.S. custom slide shoe market is rapidly maturing, placing higher demands on manufacturers—not only the ability to produce, but also the ability to understand the market, execute customization, and ensure reliable delivery. This is precisely the context in which Deran’s 21 years of manufacturing expertise continues to deliver value.

Why Choose Deran for Custom Slide Shoe Production

As a leading U.S. custom slide shoe manufacturer, Deran has 21 years of professional manufacturing experience (since 2005), focusing on the R&D and production of clogs, flip-flops, jibbitz-style footwear, and fur slippers.

- Experience and expertise: Deran has accumulated extensive international cooperation experience and maintains long-term partnerships with brands in Europe, the United States, and Southeast Asia. The company is familiar with the design requirements and quality standards of different markets. Whether serving startups or established retailers, Deran provides tailored solutions to ensure each pair of slide shoes meets specific customer needs.

- Factory scale and production capacity: Deran operates a modern factory covering 4,000 square meters, equipped with four efficient production lines and a monthly capacity of up to 400,000 pairs. Fully automated injection molding machines, laser cutting equipment, and multiple assembly lines ensure high efficiency and consistent quality, meeting both small- and large-batch production demands.

- International certifications and environmental commitment: Deran’s products have passed multiple international certifications, including TUV, REACH, and ROHS, with some materials certified under OEKO-TEX Standard 100. The factory consistently uses environmentally friendly materials such as EVA, natural rubber, linen, and bamboo fiber blends to ensure products are non-toxic and safe from the source. Exhaust treatment and water recycling systems are implemented during production to support green manufacturing and provide brands with products that meet global sustainability standards.

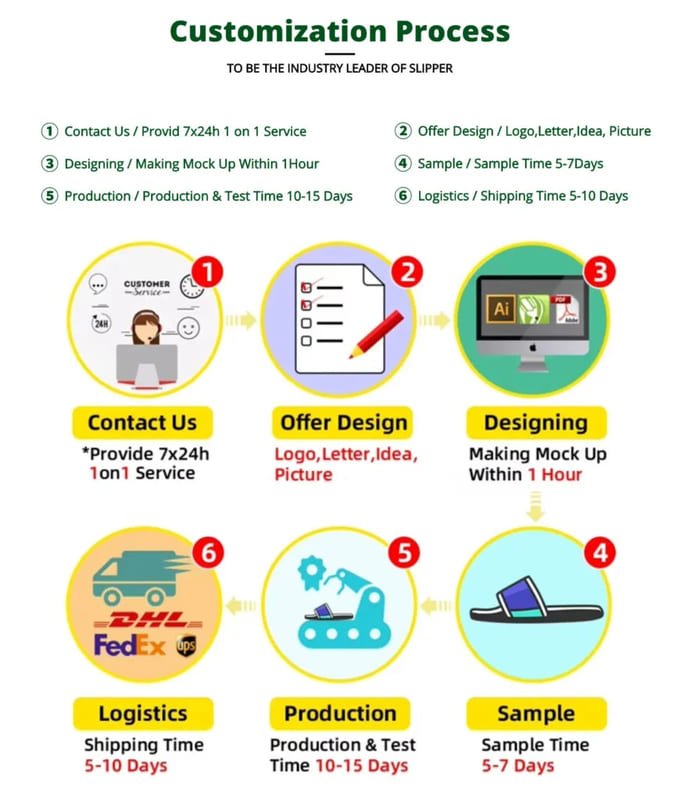

- Customization flexibility: Deran supports a wide range of customization services, including precise Pantone color matching, material selection, footwear design, logo and pattern application (silk screen printing, heat pressing, transfer printing, embroidery, etc.), and packaging customization. Customers may provide creative concepts, drawings, or samples. Deran’s design team can create a model within one hour and complete sample development within 5–7 days.

- Customer cases and professional advice: Deran has provided OEM / ODM services to more than 300 overseas clients, including Amazon brands, retail chains, and brand agents. For brands seeking rapid market entry, Deran not only offers high-quality production capabilities but also helps reduce inventory pressure and improve market responsiveness through flexible customization.

Full-Process Service for Custom Slippers

Many companies considering custom slippers are most concerned about: Is the process complicated? How much time and effort will be required? At Deran, the entire customization process is clearly designed and efficient, with every step traceable from idea to finished product.

Requirement Communication

Clients first communicate with Deran’s sales team to clarify their goals: corporate promotional gifts, hotel room slippers, or a retail product? Different applications will determine the slippers’ material, design, and budget.

Design and Proposal Development

Deran’s designers will use AutoCAD and 3D modeling tools to provide a preliminary design based on the client’s brand image and needs. The design allows the client to visually visualize the slipper’s shape, color scheme, and logo placement.

Prototyping and Confirmation

Once the design is confirmed, the factory will produce a small batch of samples. These samples are not only used to verify the appearance, but also undergo tests for comfort, slip resistance, and wear resistance to ensure they meet the client’s requirements.

Mass Production

Once the samples are confirmed, the factory will enter full production. Advanced automated equipment ensures production efficiency, while a strict quality inspection system ensures product consistency.

Quality Inspection and Shipping

Each batch of products undergoes multiple inspections, including appearance, dimensions, weight, and slip resistance testing. Once qualified, they are packaged and ultimately shipped internationally.

Deran also offers both OEM and ODM models. Brands with established designs can choose the OEM model. Clients lacking design capabilities can leverage Deran’s ODM services to create unique slippers from scratch.

Deran’s Custom Slide Shoe Services and Capabilities

As a professional manufacturer deeply rooted in the slipper and casual footwear industry, Deran has established a mature and highly flexible service system for custom slide shoe production. Leveraging over 20 years of manufacturing experience, stable capacity, and extensive international market cooperation, Deran delivers practical customization solutions for clients of different sizes and market positions, bridging the gap between product customization and market fit.

1. Comprehensive customization options

Deran’s slide shoe customization extends beyond basic style adjustments, covering appearance, structure, materials, and brand presentation:

- Color customization: Precise Pantone color matching for brand color extensions, product series development, or seasonal collections.

- Material selection: Options include EVA, TPR, PVC, rubber, and PU, balancing comfort, durability, slip resistance, and cost.

- Logo and branding: Silk screen printing, heat pressing, and transfer printing ensure clear and durable brand identification for retail, e-commerce, and gift applications.

- Style and structural customization: Adjustments to foot feel, upper width, and sole thickness to suit different markets and wearing habits.

- Packaging customization: Custom boxes, labels, or simplified e-commerce packaging to enhance professional presentation.

2. Coexistence of small-batch and large-scale production

Deran’s capacity configuration balances flexibility with stability:

- Low MOQ support: Minimum order quantity as low as 50 pairs, ideal for new brands, test runs, or limited editions.

- Stable mass production: Monthly capacity of approximately 400,000 pairs to support long-term supply for established brands, e-commerce sellers, and wholesalers.

- Controlled lead times: Rapid scheduling and reliable delivery while maintaining consistent quality, meeting basic U.S. market timing expectations.

3. Custom solutions for different industries and target audiences

Based on long-term insights into U.S. slide shoe consumption scenarios and end-user needs, Deran tailors customization by industry and audience:

- Sports and leisure brands: Lightweight, slip-resistant, and durable slide shoes for post-workout wear, daily leisure, or gym use.

- Fashion and lifestyle brands: Personalized colorways, creative graphics, and special materials to position slide shoes as fashion items rather than purely functional products.

- Hotels, apartments, and clubs: Comfort- and durability-focused solutions with custom logos for guest rooms, pools, and leisure areas.

- Promotional gifts and corporate customization: Low-MOQ, fast-turnaround solutions combining practicality with brand exposure.

- E-commerce and cross-border sellers: Multi-style, small-batch parallel customization to quickly respond to trends, control inventory risk, and speed up new product launches.

Through this industry- and audience-oriented approach, Deran acts not only as a manufacturer but also as a long-term partner for brands developing slide shoe product lines.

Deran Custom Slippers Success Story Sharing

To help customers more intuitively understand Deran’s strengths, we’ll share several typical case studies:

Sports Brand Collaboration Case Study

A well-known American sports brand collaborated with Deran to launch a co-branded pair of slippers, featuring environmentally friendly EVA material and a unique logo design. Upon launch, the product achieved impressive sales in the retail market and enhanced the brand’s environmental image.

Hotel and Resort Case Study

Several five-star hotels have chosen Deran for their customized high-end room slippers. These slippers are not only comfortable and durable, but also feature non-slip soles, enhancing the overall guest experience.

Corporate Promotional Gift Case Study

A technology company ordered a large quantity of custom slippers for its product launch as gifts for attendees. This creative marketing strategy helped the company gain significant exposure.

These cases clearly demonstrate that Deran is more than just a manufacturer; it’s a vital partner in our clients’ brand strategies.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

As the U.S. casual footwear market continues to mature, slide shoes have evolved from simple functional products into an important category combining comfort, design, and brand expression. For brands looking to enter or expand in this market, selecting a partner with long-term manufacturing experience, stable capacity, and a true understanding of customization needs has become a decisive factor in product success.

With more than two decades of production experience in slippers and casual footwear, Deran has established a clear and mature system for custom slide shoe manufacturing. From low-MOQ orders to large-scale delivery, and from basic customization to industry- and audience-specific solutions, Deran consistently transforms product concepts into market-ready results through practical manufacturing capabilities.

In an increasingly competitive U.S. market, truly outstanding custom slide manufacturers go beyond production support by continuously empowering brands through quality stability, delivery reliability, and customization flexibility. For companies seeking a trustworthy partner for custom made slides, Deran stands out as a choice combining experience, capability, and long-term cooperative value.