Table of contents

Deran’s Factory Strength and Manufacturing Experience

- Factory Scale and Equipment

Deran has been established for 20 years and is a leading custom slide manufacturers in China. The factory covers over 20,000 square meters and includes modern production workshops with a professional management team. It is equipped with more than 200 automated and semi-automated machines, including high-speed injection molding machines, heat-press machines, and precision cutting equipment. These ensure efficient and stable production of custom slides, maintaining consistency in craftsmanship and dimensional accuracy. - Production Capacity

Deran can handle a wide range of orders, from small custom batches to large-scale custom slides wholesale orders. The factory has a systematic production management process, overseeing every stage from raw material procurement, cutting, injection, assembly to finished product delivery, ensuring high-quality orders are delivered on time. - Technical R&D and Innovation

Deran operates its own R&D center with professional designers and engineers. They continuously optimize slide designs and production processes, researching new material combinations, ergonomic shoe shapes, as well as anti-slip and wear-resistant technologies. This keeps Deran’s custom slides competitive in comfort, durability, and functionality. - Rich Experience

With 20 years of manufacturing experience, Deran expertly handles diverse orders, including sports slides, casual slides, and branded custom designs. This experience enhances production efficiency and allows flexible response to market changes and specific client requirements, ensuring reliable, high-quality custom slides.

High-Quality Materials and Custom Manufacturing Process

Material Selection

Deran strictly follows international standards in sourcing materials, including eco-friendly EVA, PU, and natural rubber. The soles, uppers, and straps are non-toxic, durable, and comfortable. All materials are tested to meet REACH and OEKO-TEX standards, ensuring safety and environmental compliance for custom slides.

Custom Manufacturing Process

- Design Phase: Clients provide their requirements or brand concepts, and Deran’s design team develops shoe shapes, colors, patterns, and functional elements.

- Sample Phase: Physical or 3D models are made for client approval, ensuring the size, color, and comfort meet expectations.

- Mass Production Phase: Skilled workers and automated machines handle precise cutting, injection, heat-press, and assembly, ensuring consistent quality of each pair of custom slides.

- Quality Testing Phase: Finished slides undergo wear, pressure, anti-slip, and comfort testing, ensuring compliance with international standards.

Customization Features

Deran provides features such as anti-slip sole textures, thickened insoles, color gradient effects, and brand logo customization. These options ensure custom slides meet high standards in comfort, durability, and visual appeal.

Advanced Quality Management and Certifications

International Certifications

Deran is ISO 9001 certified, ensuring standardized and traceable production processes. Its slides also comply with REACH, OEKO-TEX, and TUV certifications, reflecting the safety, environmental compliance, and professional manufacturing standards of a trusted custom slide manufacturers.

Quality Control Process

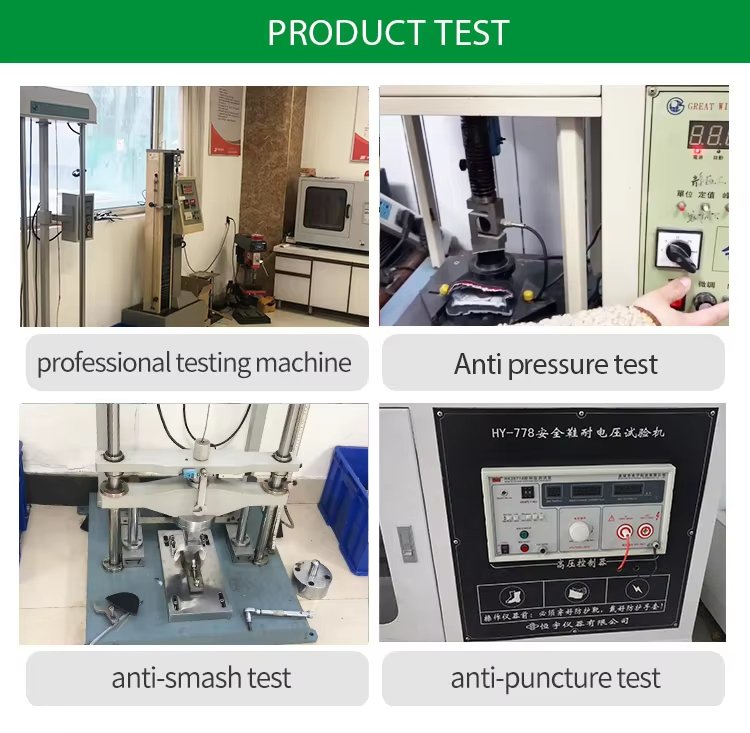

- Raw Material Inspection: Each batch undergoes testing for composition, wear resistance, tensile strength, and environmental compliance.

- Production Monitoring: Critical stages such as injection, heat-press, and sole assembly are supervised by dedicated quality inspectors to detect any deviations.

- Finished Product Sampling: Each slide batch undergoes anti-slip, pressure, wear, and comfort tests to ensure products meet client expectations.

Quality Data

Deran maintains consistently high batch pass rates and stable client satisfaction, demonstrating its reliability and authority in the custom slide manufacturers market.

Custom Service Process and Client Collaboration Experience

Order Process

- Requirement Communication: Clients submit design requirements, functional needs, and quantities; Deran offers professional advice on material selection, shape optimization, and functional enhancements.

- Sample Production and Approval: Rapid prototyping typically completed within a week for client confirmation.

- Mass Production and Delivery: Production based on approved samples; timelines depend on order complexity and size.

- After-Sales Support: Quality tracking, technical consultation, and product optimization guidance ensure client satisfaction.

Collaboration Experience

Deran has partnered with multiple domestic and international brands, including sports brands, retail chains, and e-commerce platforms. Their experience allows efficient handling of diverse requirements and challenges, meeting the demand for large custom slides wholesale orders during peak seasons.

Deran’s Market Advantages and Future Trends

Market Advantages

- Experienced: 20 years of custom slide production, understanding market needs and production challenges.

- Technological Innovation: R&D team continuously improves design and processes, enhancing comfort, durability, and functionality.

- Flexible Production: Capable of small custom batches or large custom slides wholesale orders, meeting diverse client needs.

- Certifications and Reputation: ISO, REACH, OEKO-TEX certifications ensure product safety, environmental compliance, and high quality.

Market Trends and Insights

- Material Technology: Lightweight EVA, eco-friendly rubber, and biodegradable materials improve comfort and sustainability.

- Functional Design: Anti-slip soles, waterproof coatings, and removable insoles are growing trends.

- Eco-Friendly Focus: Consumers increasingly demand sustainable products, requiring manufacturers to consider recyclable materials and green production.

Wholesale Client Tips

When selecting suppliers, consider factory scale, equipment, and R&D capabilities to ensure stable large-scale delivery.

Check quality management systems and certifications to guarantee safe and reliable products.

Maintain effective communication, clarify design, prototyping, production, and delivery timelines to avoid delays.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

As a leading custom slide manufacturers in China, Deran leverages 20 years of manufacturing experience, a professional R&D team, advanced equipment, and strict quality management systems to provide high-quality, flexible, and reliable custom slides wholesale. Whether for small custom orders or large-scale wholesale, Deran delivers full-service solutions from design to after-sales. Choosing Deran means selecting a trusted, experienced, and technologically advanced partner capable of meeting diverse market and consumer needs.