Table of contents

- Deran’s Unique Advantages: Why Choose Them for Custom Slide Shoes

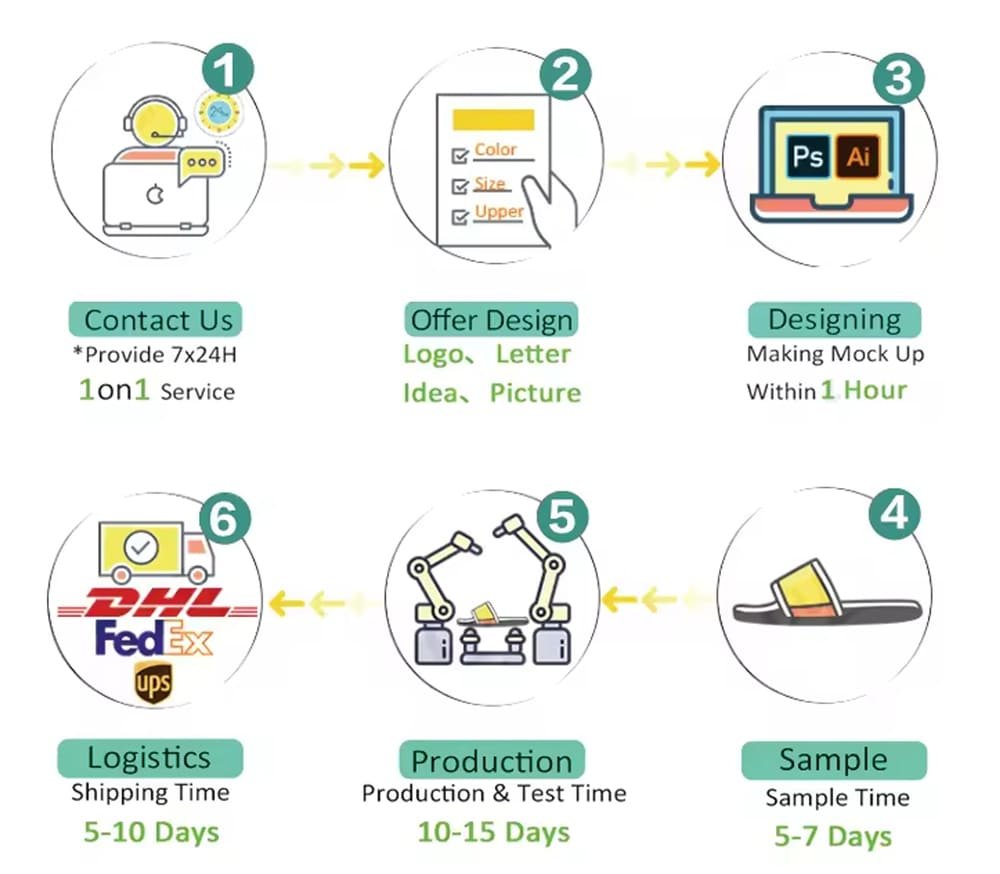

- Custom Slide Shoe Process: From Concept to Final Product

- Deran’s Professional Materials and Process Advantages: Creating High-Quality Slide Shoes

- Collaboration Guide and Practical Tips: How to Work Smoothly with Deran

- FAQ and Key Considerations

Deran’s Unique Advantages: Why Choose Them for Custom Slide Shoes

Choosing Deran as a partner means obtaining high-quality custom made slides and professional services. Here are its core advantages:

- Rich Industry Experience: Since its establishment in 2005, Deran has focused on producing custom Slide shoes, accumulating more than twenty years of extensive experience. This long-term expertise allows them to handle various production challenges efficiently, ensuring that every pair of shoes meets high standards.

- Advanced Production Equipment and Modern Factory: Deran owns over 200 production machines, including high-precision injection molding machines, automated sole forming equipment, and multifunctional sample centers. These machines ensure high precision and consistency in production, supporting both small batch customization and large-scale manufacturing, providing flexible production solutions for clients.

- Professional R&D and Design Capabilities: Deran has an experienced design team familiar with footwear material properties and the latest fashion trends. The team provides personalized design solutions based on client needs, including shoe structure, color options, and logo customization, ensuring each pair is functional while reflecting the brand identity.

- Strict Certifications and Quality Assurance: Deran’s products are certified by ISO9001, REACH, and OEKO-TEX, guaranteeing material safety and reliable production processes. Multiple quality control measures cover raw materials, production, and finished products, ensuring that each shoe meets strict standards for comfort, durability, and safety.

- High-Quality Customer Experience: Deran offers full-service support from creative communication and sample production to mass production. Clients can provide feedback during the sample stage, and the design team offers professional guidance to ensure the final product meets expectations, enhancing the overall collaboration experience.

Custom Slide Shoe Process: From Concept to Final Product

- Initial Design and Creative Communication: Clients can communicate their ideas with Deran’s design team online or offline, covering shoe shape, color, pattern, and functional requirements. Providing brand elements such as logos or patterns helps the design team accurately reflect client needs and reduces later modifications.

- Material Selection: Deran offers a variety of sole materials, including EVA, PU, and rubber, with options for eco-friendly, recyclable materials. EVA is lightweight and soft, suitable for casual daily wear; PU is durable, suitable for outdoor activities; rubber provides excellent slip resistance for various surfaces.

- Sample Production and Modifications: After finalizing the design and materials, Deran produces high-precision samples, typically within 7-10 days. Clients can provide modification feedback at this stage, and the design team will offer professional suggestions to ensure the final product meets expectations.

- Mass Production Process: Once samples are approved, Deran proceeds to mass production. Automated production lines with key quality checkpoints ensure that each shoe’s size, color, and material match the approved sample. Production typically takes 15-25 days depending on the order quantity.

- Quality Inspection and Final Delivery: Deran has a comprehensive quality inspection process covering raw materials, production monitoring, and finished product checks. Inspections ensure sole durability, upper smoothness, and shoe shape stability. Finished products are carefully packaged and delivered worldwide.

Deran’s Professional Materials and Process Advantages: Creating High-Quality Slide Shoes

- Core Material Advantages: Deran selects high-quality EVA, PU, and natural rubber for soles, while the uppers are made from soft and durable PU or high-elastic fabric. EVA is lightweight and shock-absorbing; PU is durable and wear-resistant; rubber provides excellent grip and slip resistance. Eco-conscious clients can choose low-VOC, recyclable materials that meet international green standards.

- Unique Production Process: Deran’s injection molding technology precisely controls sole hardness and shoe structure, enabling complex shoe shapes. Heat-pressing and bonding processes ensure upper-to-sole stability, while automated mold adjustment ensures high-precision customization and consistent comfort.

- Comfort and Durability: Scientific shoe design and material combinations ensure moderate sole elasticity and a soft, foot-conforming upper for maximum comfort. Wear-resistant rubber soles and high-strength stitching extend product life, while slip-resistant textures combine safety with aesthetics.

- Sustainable Manufacturing Practices: Deran reduces waste and energy consumption in production, uses recyclable materials, and complies with OEKO-TEX standards. Green packaging solutions reduce logistics carbon emissions, aligning environmental responsibility with corporate values.

Collaboration Guide and Practical Tips: How to Work Smoothly with Deran

• Understand Minimum Order Quantity and Sample Cycle

Deran accepts small batch orders, with a minimum quantity of approximately 50 pairs. Sample production takes 7-10 days, allowing clients to provide modification feedback to ensure that mass production meets expectations.

• Provide Clear Designs and Brand Elements

Clients should provide design files, logos, color schemes, and functional requirements to facilitate feasibility analysis and optimization by the design team.

• Maintain Effective Communication with the Design Team

Through video calls or online platforms, clients can monitor sample progress, provide feedback, and track production status in real-time, ensuring every detail meets requirements.

• Ensure On-Time Delivery and Quality Compliance

Deran’s strict quality control and mass production management ensure product reliability. Clients can confirm delivery schedules and logistics plans before signing contracts to guarantee timely arrival.

FAQ and Key Considerations

• Production Cycle and Minimum Order Quantity

Sample production: 7-10 days, mass production: 15-25 days depending on order size, minimum order: approximately 50 pairs, suitable for both trial orders and large-scale production.

• Material Selection

EVA is lightweight and soft for casual use, PU is wear-resistant for outdoor activities, rubber offers strong grip and slip resistance. Eco-conscious clients can choose low-VOC and recyclable materials.

• Finished Product Shipping and After-Sales Service

Deran provides worldwide logistics solutions to ensure safe delivery. After-sales services include quality issue handling, modification suggestions, and long-term cooperation support.

• Modifications and Changes in Custom Requirements

Clients can provide modification feedback during the sample stage. Confirming the final design before mass production reduces rework and ensures the product meets expectations.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

With over twenty years of industry experience, advanced equipment, a professional design team, and strict quality control, Deran has become a leading US custom slide manufacturers. Whether for brand promotion, corporate customization, or personal creativity, Deran provides end-to-end solutions from design to delivery. By working with Deran, clients gain not only high-quality, comfortable, and durable custom made slides, but also a professional, reliable, and personalized service experience. Choosing Deran means selecting a trusted partner that delivers real value for your brand or custom needs.