Table of contents

Design Concept and Strategy

The first step in custom Jibbitz production is creative design. Whether for brand customization or personal products, the concept phase determines the efficiency of the entire production process and the quality of the final product.

Market Trends and Consumer Preferences

- The most popular Jibbitz types include cartoon characters, holiday elements, brand logos, and fun text decorations.

- Young consumers prefer interchangeable and interactive charms, while the children’s market favors bright colors and cute designs.

- Design inspiration can come from social media (Instagram, Pinterest), trend websites, and footwear exhibitions to ensure market relevance.

Materials and Color Strategy

- Common materials for Jibbitz include PVC, TPR, silicone, and metal, while Deran also offers eco-friendly options like EVA, natural rubber, linen, and bamboo fiber blends.

- Color design must match the shoe and overall style, while ensuring lightfastness and wear resistance.

- Deran follows international environmental standards (REACH, RoHS) to ensure products are safe, reliable, and suitable for export.

Digital Design and Visualization

- Professional software such as CAD, Adobe Illustrator, and 3D modeling is used to transform concepts into precise digital models.

- Digital design improves efficiency and allows clients to preview sample effects, reducing modification costs.

- For complex shapes, Deran provides design optimization advice to ensure aesthetics and manufacturability.

Customization Process Explained

Deran’s customization process has been refined over years of experience, carefully managing each step from client requirements to finished products to ensure high-quality Jibbitz that meet creative expectations.

- Client Needs and Communication: Deran provides 24/7 one-on-one support to understand client requirements, including design ideas, material preferences, quantities, and brand elements. Clients can provide sketches or images, and Deran’s team offers creative solutions for those without design experience, ensuring ideas are both marketable and brand-relevant.

- Sample Production and Adjustment: After confirming the design, Deran produces samples within 5–7 days. Clients review materials, dimensions, and colors, and provide feedback. Deran’s rapid iteration ensures adjustments are implemented promptly, guaranteeing accuracy before mass production.

- Small-Batch Trial Production: Small-batch trials verify production processes, material compatibility, and overall effect, allowing clients to experience the product early and identify potential improvements. Packaging and transportation are also simulated to ensure stability and reliability.

- Mass Production and Delivery: After sample approval, mass production begins. Deran’s factory, a trusted custom jibbitz manufacturer, flexibly schedules production lines based on order volume. Monthly capacity reaches 400,000 pairs of slippers, with single batches completed in as fast as 12–24 hours. Shipping options include courier, air, and sea; samples are delivered within a week, and full orders usually within 30 days.

- After-Sales Support: Deran provides full after-sales support, including quality issue resolution, design optimization advice, and reorder management, ensuring smooth long-term collaboration.

Custom Jibbitz Production Steps Explained

Deran breaks down Jibbitz production into precise stages, ensuring consistent quality and accuracy.

Material Preparation

- Materials include PVC, TPR, silicone, EVA, natural rubber, linen, and bamboo fiber blends.

- All materials meet environmental and safety standards, suitable for children and adults.

Process Selection

- Common processes: injection molding, soft rubber molding, 3D printing, multi-material combinations.

- Complex shapes use multi-step processes to ensure detail precision.

Production Management

- Production sequence: mold preparation → material injection → molding and cooling → trimming → coloring/printing → inspection.

- Each step is monitored to ensure size accuracy, color consistency, and appearance quality.

Small-Batch Trial

- Small-batch trials verify production techniques, assess efficiency, and identify potential issues.

- Clients can experience the product early, facilitating design improvements.

Mass Production

- Deran has 4 high-standard production lines, monthly capacity of 400,000 slippers, capable of handling small to large orders.

- Automated equipment and standardized procedures improve efficiency and ensure timely delivery.

Deran’s Custom Service Strengths

Deran’s advantages in custom Jibbitz services are divided into two main aspects:

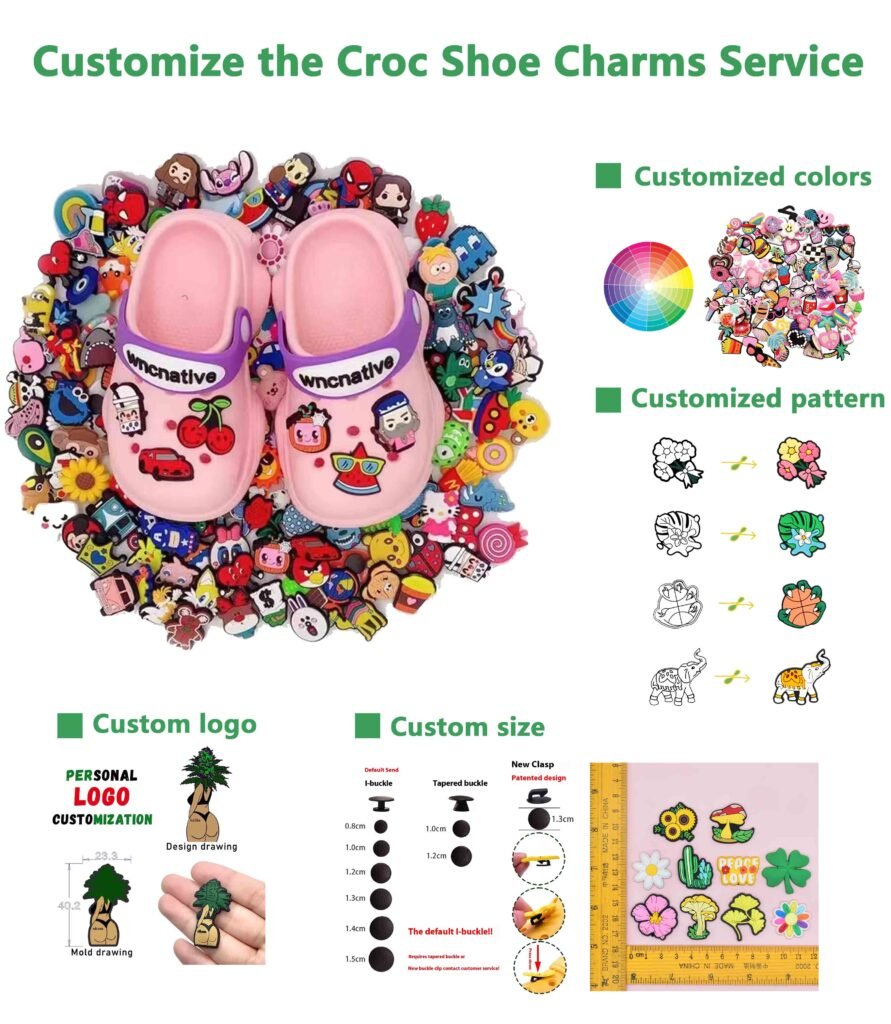

1. Flexible OEM/ODM Services

- Customization Projects: Logo personalization, color and pattern selection, material choice (PVC, TPR, silicone, EVA, natural rubber, linen, bamboo fiber blend), packaging customization, sample production and adjustments.

- Service Modes: Offers pure OEM, ODM, or mixed modes to meet various client needs.

- Minimum Order Quantity: Customized Crocs: 200 pairs; Slippers: 50 pairs; Flip-flops: 1,500 pairs; Jibbitz: 500 pieces.

2. Custom Service Advantages

- Rich Experience: 20 years in footwear and Jibbitz production, with global exports and understanding of international markets.

- International Certifications: Products comply with REACH, RoHS, and other safety and environmental standards.

- Professional Team: Designers, project managers, and customer service provide full guidance for smooth workflow.

- Rapid Response: Single batch production can be completed within 12–24 hours.

- Reliability: Long-term OEM partner for global brands, ensuring product consistency and high quality.

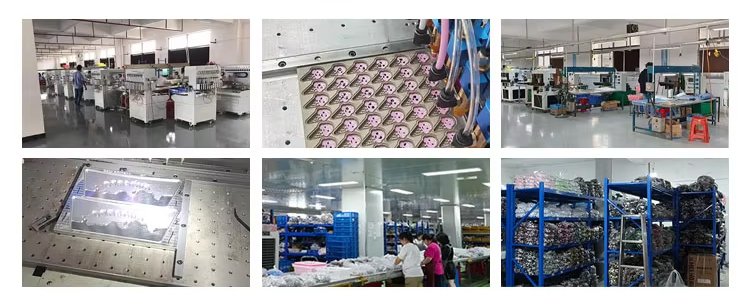

Deran’s Factory Strengths and Efficient Production Capabilities

- Factory Scale and Equipment: Founded in 2005, Deran has 4 high-standard production lines with injection machines, 3D printers, and precision molds. Spacious and safe workshops ensure smooth production and support diverse customization needs.

- Production Efficiency: Monthly capacity reaches 400,000 pairs of slippers. Automated equipment and standardized procedures enable both small and large orders to be completed efficiently, with single batches produced in 12–24 hours.

- Quality Management: Each product undergoes strict inspection for size, color, durability, and environmental standards, complying with ISO and global safety requirements, ensuring consistency and reliability.

- Materials and Supply Chain: All materials are traceable and carefully selected to ensure stable production and high-quality products. Samples are delivered within a week, with full orders usually completed within 30 days.

- Client Support and Flexibility: Professional project management oversees every stage, providing design advice, production guidance, and logistics support to ensure rapid delivery of customized products.

- Environmental Sustainability: Deran uses eco-friendly materials (EVA, natural rubber, linen, bamboo fiber blend) and implements green manufacturing practices, meeting international export standards and demonstrating social responsibility.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

With 20 years of experience in slippers and Jibbitz production, Deran provides a complete, professional, and reliable custom jibbitz manufacturer and custom jibbitz wholesale solution from concept to finished product.

Deran ensures every product is high-quality through flexible OEM/ODM services, advanced equipment, and a professional team. Whether for designers, brands, or retailers, collaborating with Deran turns creative ideas into market-ready, personalized products. By focusing on detail, maintaining efficient communication, and leveraging Deran’s expertise in materials, processes, and quality control, each custom Jibbitz becomes a unique connection between brands and consumers, reflecting personality and creative value.