Table of contents

Deran’s Top Manufacturing Strength

- Extensive Experience and Industry Focus: Since its establishment in 2005, Deran has specialized in OEM/ODM custom production of wooden clogs, flip-flops, Clogs-style shoes, and fur slippers for 20 years. With long-term technical accumulation, Deran has become a globally trusted crocs shoes manufacturer, capable of providing clients with one-stop solutions from small-batch customization to large-scale production.

- Factory Size and Production Capacity: Deran’s factory covers more than 10,000 square meters and has 4 fully automated production lines, with a monthly production capacity of 400,000 pairs. The efficient production system offers flexible options for clients, whether for small trial orders or large-scale shipments.

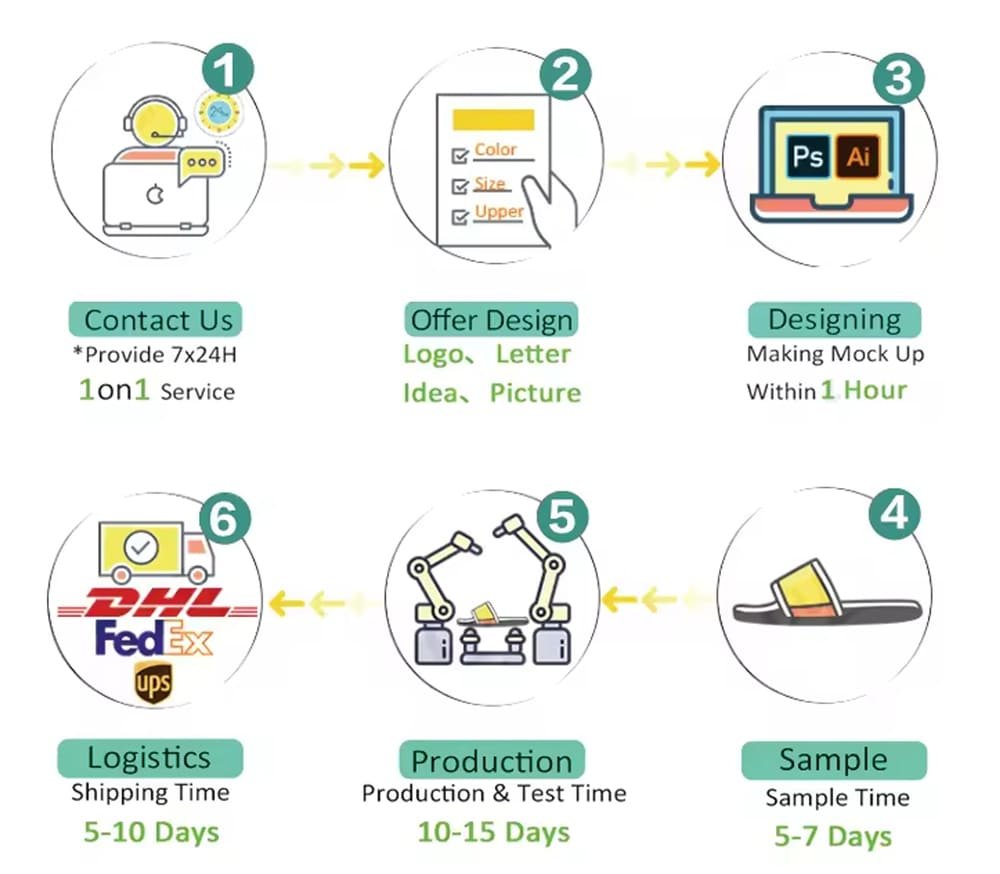

- Small-Batch Minimum Order and Rapid Prototyping: Minimum orders for Crocs shoes are 200 pairs, flip-flops 1,500 pairs, Clogs-style shoes 500 pieces, and other slippers 50 pieces. Sample production takes 5-7 days, and design models can be completed within 1 hour, saving clients valuable time and enabling fast market entry.

- International Certification and Environmental Standards: Deran strictly follows international standards, using eco-friendly materials such as EVA, natural rubber, linen, and bamboo fiber blends, and holds certifications including REACH, ROHS, OEKO-TEX, and TUV. These sustainable materials ensure comfort and durability while meeting global demands for environmentally friendly products.

- Professional Team and Customer Service: Deran has a professional sales and service team offering 24/7 online support. The company adheres to the principle of “Customer First, Innovation Driven,” ensuring smooth operations in every cooperation step and providing clients with full professional support.

Deran’s Customization Process

Deran has established a mature and efficient system for custom made crocs, ensuring that every pair meets client requirements and international standards.

- Design Stage: Deran provides full customization options, including shoe style, color, buckles, straps, and personalized decorative elements. Clients can provide their own designs, logos, text, or creative images. Deran’s design team can complete design models within 1 hour and optimize them based on client needs, quickly verifying appearance and functionality.

- Sample and Prototype Validation: Sample production takes 5-7 days, allowing clients to review comfort, color, and appearance. Deran then adjusts and optimizes the design based on feedback, minimizing risk before mass production.

- Mold Making and Mass Production: Deran has a professional mold team to design high-precision molds, ensuring consistent shoe body and sole formation. Mass production uses advanced injection molding equipment to achieve high efficiency and stable quality.

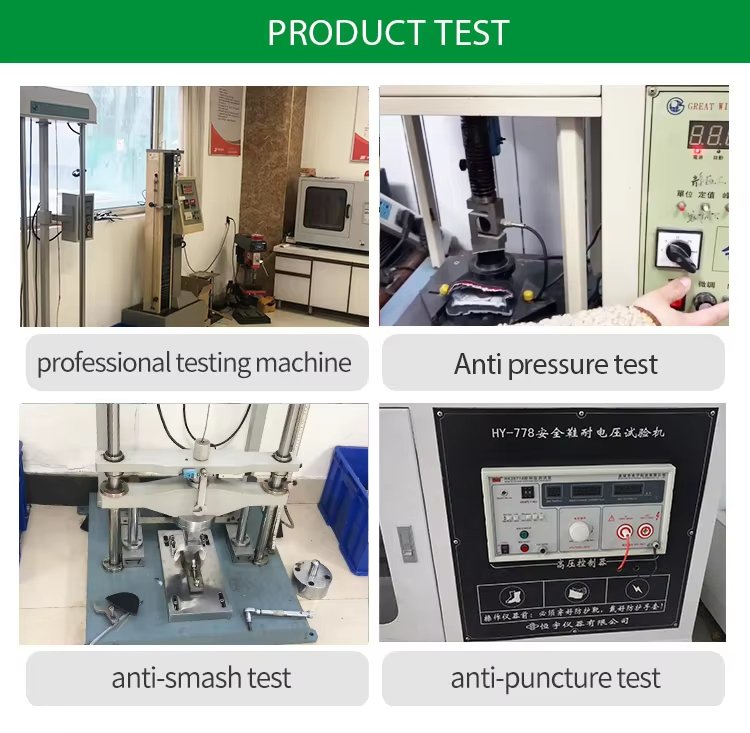

- Pre-Delivery Quality Inspection: Before shipment, strict quality inspections are conducted, including size measurement, hardness tests, wear resistance checks, and sole adhesion tests. Each batch is certified by both internal and third-party inspections to ensure compliance with international standards.

Materials and Craftsmanship: Comfort and Durability

- High-Performance Material Selection

Deran prioritizes Croslite material, a lightweight foam resin that is soft, comfortable, wear-resistant, and slip-resistant, effectively reducing foot fatigue. Other options include EVA, natural rubber, linen, and bamboo fiber blends to meet diverse market and consumer needs. - Advanced Injection Molding Process

High-precision injection molding equipment ensures tight bonding between shoe body and sole, maintaining consistency and structural stability. This process enhances durability and support. - Functional Design Optimization

Anti-slip textures on the sole improve grip; ventilation holes ensure airflow for enhanced comfort. Key wear areas on the sole and upper are treated to extend shoe lifespan. - Environmental and Sustainable Practices

Deran strictly follows international environmental standards, prioritizing recyclable and low-VOC materials. The company promotes full-chain ecological recycling, meeting global green consumer trends.

Quality and Safety Assurance

Quality and safety are core principles for Deran. Certified under ISO 9001, Deran has established a comprehensive quality control system, strictly monitoring every step from raw materials to finished products.

Internal Testing Tools and Procedures

- Hardness Tester: Ensures sole elasticity and consistent comfort

- Wear Resistance Tester: Tests sole durability

- Sole Pull Test: Guarantees firm adhesion of sole to shoe body

Children’s shoes emphasize soft soles and slip resistance, while adult shoes focus on support and comfort. Deran also cooperates with third-party inspection agencies to conduct random checks, ensuring every batch meets international safety standards and client trust.

Deran’s Custom Advantages

- Small-Batch Customization and Fast Response: Deran supports small-batch orders, with single-batch production completed in 12-24 hours, allowing clients to quickly test products and respond to market trends.

- Personalized Shoe Design: Clients can create unique styles through color, shoe type, buckles, and decorative elements, enhancing brand recognition and competitiveness.

- Flexible Materials and Styles: Options include Croslite, EVA, natural rubber, linen, and bamboo fiber blends. Sole thickness, textures, and upper decorations can be adjusted to ensure both aesthetics and functionality.

- High Quality and Environmental Assurance: Compliance with international certification standards ensures product stability and quality. Eco-friendly materials and sustainable processes enhance brand social responsibility and long-term trust.

- Comprehensive Customer Service System: 24/7 online support covers design communication, sample production, and mass production. Clients can visit the factory at any time to inspect production and quality control, building trust and long-term cooperation.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

With 20 years of industry experience, advanced equipment, comprehensive quality systems, and flexible customization, Deran has become a leading global crocs shoes manufacturer. Whether for small-batch trial orders or large-scale production, Deran delivers high-quality, eco-friendly, safe, and personalized Crocs shoes.

Choosing Deran allows clients to obtain comfortable, durable shoes while enhancing brand competitiveness and market responsiveness through custom services. In the global footwear market that pursues personalization and high quality, Deran’s custom advantages provide reliable support for unique products, strengthening brand influence worldwide.