Table of contents

Over the past decade, Crocs shoes have transformed from simple functional footwear into a fashion statement thanks to their lightweight, comfortable, and highly recognizable design. According to market research firm Statista, global Crocs sales exceeded $2.7 billion in 2024 and have continued to grow at a CAGR of approximately 8% (Source: Statista 2025 Footwear Market Report). Behind this trend is a growing demand from consumers for personalization and enhanced comfort. Therefore, “customized Crocs shoes,” as a product that blends design aesthetics with comfort, are increasingly becoming a vehicle for brands and individuals to express themselves.

Deran, as a professional manufacturer specializing in customized Crocs shoes, not only provides production capabilities but also helps clients realize their ideas from concept to finished product through a complete set of mature processes and services.

Deran Custom Croc shoes Factory

Deran’s Founding and Growth

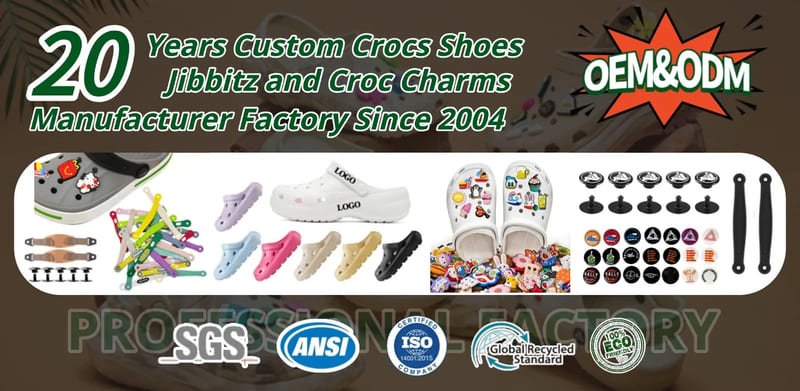

Founded in 2008, Deran initially focused on OEM manufacturing of lightweight footwear. With the global surge in popularity of Crocs shoes, Deran strategically began developing a custom Crocs production line in 2015. Through continuous investment in equipment and R&D talent, it has gradually grown into a leading custom manufacturer in the industry. By 2025, Deran has served over 300+ brand clients worldwide, producing over 1.5 million pairs of custom Crocs.

Deran’s success is inseparable from its keen insight into industry trends and its consistently rigorous pursuit of quality. The Deran factory has passed ISO 9001 quality management system certification and BSCI social responsibility certification. These authoritative certifications not only demonstrate the factory’s standardized operations but also ensure that product manufacturing processes meet international standards.

Deran’s Production Scale and Certifications

The Deran factory is located in a manufacturing hub in Southeast Asia, covering an area of over 30,000 square meters, and boasts modern workshop facilities, environmentally friendly emission systems, and automated production lines. The factory has an annual production capacity of over 5 million pairs of shoes, with custom-made Crocs making up a significant proportion.

Deran’s certifications include:

- ISO 9001 Quality Management System Certification

- BSCI Social Responsibility Certification

- Factory audit passed global renowned brand supplier standards

- Multiple environmentally friendly materials comply with REACH/CPSIA/RoHS standards

These certifications not only guarantee quality for customers but also greatly enhance Deran’s reputation and cooperation opportunities in the international market.

Deran focuses on professional equipment and technology for custom Crocs

Deran utilizes industry-leading 3D printing prototyping technology, CNC mold machining centers, and automated injection molding systems to ensure precision and efficiency at every step from design to finished product. Compared to traditional footwear production, Croc customization has its unique characteristics, such as:

- The sole injection molding requires a specific PU/EVA blend formula.

- The upper needs precise color matching based on the patterns and colors provided by the customer.

- Standard Croc eyelet placement and ventilation hole structure must conform to the original design logic.

Deran’s professional team is well-versed in these technical aspects and, combined with advanced equipment, transforms complex customization needs into stable, mass-producible products.

Detailed Guide to Custom Crocs Shoes

A successful customization project relies on a clear and standardized process. Whether you’re a brand owner or a designer, mastering the customization process can significantly improve project efficiency and final product quality. Here are Deran’s recommended steps:

Consultation and Design Requirements Communication

The first step is to clarify your design vision:

- Identify your target users and market positioning. For example: children, trendy young people, outdoor users, etc.

- Prepare design references. This can include hand-drawn sketches, color swatches, color schemes, or brand visual guidelines.

- Communicate core functional requirements. Whether special outsoles for slip resistance, durability, or uniquely shaped shock-absorbing insoles are needed, etc.

Template Development and Sample Production

Once the design is confirmed, Deran will initiate the sample production process:

- 3D Model Building: Creating a digital 3D template based on the artwork.

- Sample Injection Molding and Hand Assembly: Creating the first physical sample shoe.

- Client Confirmation and Modifications: Adjusting the design, color scheme, or materials based on sample feedback.

A complete sample production cycle typically takes 7–14 days. To improve efficiency, Deran also offers priority expedited sample service (completed within 5 days).

During the sample confirmation stage, if color comparison verification is required, Deran recommends that customers use the Pantone standard color chart for color matching confirmation. This effectively avoids color discrepancies between online and physical samples.

Mass Production and Quality Control

After sample confirmation, mass production begins. Deran’s production process includes:

- Material Procurement: Environmentally friendly materials are sourced from certified suppliers.

- Production Scheduling: Production plans are developed based on order volume.

- Injection Molding and Upper Assembly

- Quality Inspection: Each pair of shoes undergoes multiple tests, including appearance, size, tensile strength, and abrasion resistance.

Deran’s quality control standards are benchmarked against international footwear brands, including:

- Size Error ±1 mm

- Color Difference ≤ 3 ∆E

- Finished Products No Obvious Defects

To ensure product stability, Deran also provides customers with a First Article Inspection (FAI) report and batch quality sampling reports.

Packaging and Logistics Solutions

Customized products typically require more sophisticated packaging and personalized presentation. Deran offers a variety of packaging upgrade options:

- Custom shoebox printing (including brand logo)

- Inner lining design (flocked lining, eco-friendly paper support)

- Accessories (shoelaces, insole tags, care manual)

How to Choose the Right Custom Crocs Shoes for You?

Determine the Use Scenario: Leisure, Work, Outdoor

Different scenarios require shoes with different functions. Lightweight styles are suitable for casual everyday wear, while work environments (such as restaurants and medical settings) require more slip-resistant and waterproof styles. Outdoor activities require thicker soles with improved grip.

Choosing the Right Sole Hardness and Thickness

A sole that is too soft may affect support, while one that is too hard may reduce comfort. When choosing the right sole thickness and hardness, consider your weight and the intensity of your daily activities. Deran offers a variety of sole options for custom shoe designs.

Personalized Shoe Accessories and Logos

A key feature of Crocs is its interchangeable shoe accessories. Whether it’s a cartoon character, a brand logo, or a unique design, personalized shoe accessories can reflect your unique style. Deran supports personalized designs to meet both brand customization and consumer needs.

Tip-On and Comfort Testing Tips

When choosing Crocs shoes, it’s recommended to try them on in the afternoon, as feet tend to swell slightly more than in the morning, more similar to their daily size. When trying on shoes, pay attention to whether there’s enough room in the toe box and whether the sole fits your foot shape. These tips can help you choose the right shoe for the right fit.

Deran’s Successful Custom Crocs Case Study

Sharing classic case studies provides a more intuitive understanding of the customization process and Deran’s professional value.

Case Study 1: Corporate Group Custom Crocs

An international technology company wanted to customize a “corporate culture-themed Crocs” for its global employees:

- Design elements included the company logo, annual slogan, and team colors.

- Quantity required: 10,000 pairs

- Special requirements: Reinforced soles, custom insole printing

Deran’s solution was:

- Providing design consultants to collaborate with the brand visual team to produce high-fidelity prototypes.

- Optimizing sole materials to balance durability and comfort.

- Implementing batch inspections during mass production and providing data reports.

The finished product received high praise from the company and became one of the employee benefits, enhancing corporate cohesion.

Case Study 2: Fashion Brand Collaboration

A well-known clothing brand collaborated with a designer to launch a limited-edition Crocs collection:

- The design style blends streetwear and high-end elements.

- It utilizes a combination of colors and materials.

- Requirement: 5,000 limited-edition pairs

Deran’s execution steps included:

- Close communication with the designer to assess the feasibility of each material.

- Pre-production sampling and color adjustments.

- Implementing limited-edition box and tag designs with specific sizes.

After its release, the collaboration garnered widespread attention from fashion media and consumers, helping the brand increase its exposure in the youth market.

Case Study 3: Limited-Edition Design by an Independent Designer

An independent designer wanted to bring their original shoe designs to life through Crocs:

- The design inspiration came from natural elements.

- Only 300 pairs were planned for production.

- The focus was on the upper embellishments and unique color schemes.

Deran provided the following:

- Personalized design optimization suggestions.

- Support for small-batch production scheduling.

- Customized packaging and a limited-edition numbering system.

After the final product was released, it generated considerable buzz on the designer’s social media platforms, paving the way for future cross-industry collaborations.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

As consumers’ demands for personalization, environmental friendliness, and comfort continue to rise, Crocs will undoubtedly see even greater growth. Deran crocs shoes manufacturer will continue to prioritize professionalism, innovation, and customer focus, continuously optimizing its processes and services to provide even higher-quality customized Crocs solutions to its global partners.