Table of contents

Crocs are undoubtedly a phenomenal presence in the global casual footwear market. Since its introduction, they have quickly become a hit among consumers of all ages thanks to their lightweight, slip-resistant, comfortable, and personalized designs. Today, Crocs are more than just functional shoes; they’ve become a lifestyle icon. People love them not only for their comfort but also for the ability to express their individuality through the colorful shoe accessories (Jibbitz).

With growing demand, more and more brands and wholesalers are seeking customized Crocs products. The core process behind this is foaming technology. The shoe’s lightness, rebounding comfort, and environmental friendliness and odorlessness are all directly related to the maturity of the foaming process, which is the core competence of Deran’s factory.

Deran is not only a crocs shoes manufacturer specializing in Crocs shoes and shoe accessories, but more importantly, through years of experience, it has developed a comprehensive solution chain encompassing foaming technology, ODM/OEM services, international certifications, and factory management. For customers, this means they can enjoy customized Crocs products that balance quality, innovation, and market competitiveness.

Basic Analysis of Deran’s Custom Crocs Foaming Technology

To understand why foaming technology is the soul of Crocs shoes, we need to examine both the materials and the process.

What is Foaming Technology?

Foaming technology, as the name suggests, involves creating uniform, microscopic bubbles within the raw material through physical or chemical methods. This creates lightweight, cushioning, anti-slip, and rebound properties in the finished shoe. For Crocs, foaming is the first step in determining comfort. Without a sound foaming process, the shoe may be too stiff, too heavy, or have uneven pores, directly impacting the wearing experience.

Common Materials: EVA and Croslite

Currently, two main materials are commonly used in Crocs-style shoes: EVA and Croslite. EVA is popular for its lightness and anti-slip properties, but it’s slightly less durable and comfortable. Croslite, a patented material, offers greater elasticity and rebound, but requires more demanding craftsmanship. Deran’s advantage lies in its ability to create the ideal finished product, regardless of the material the customer requires, through precise foaming ratios and process control.

The Critical Role of Foaming

In Crocs manufacturing, the foaming process impacts far more than just the lightweight feel of the sole:

- Comfort: Optimized foaming creates a soft yet supportive shoe, preventing the discomfort of collapse or stiffness.

- Lightness: By controlling the foaming density, the shoe maintains strength while minimizing weight.

- Slip resistance: The foam material complements the sole’s tread pattern, enhancing traction.

- Environmental and health: High-quality foaming prevents the release of odor and harmful substances, ensuring skin-friendly comfort.

In other words, foaming technology defines the “soul” of Crocs shoes, and Deran’s expertise lies in perfectly capturing this soul.

Deran’s Innovation in Foaming Technology and Factory Advantages

For customers seeking customized Crocs products, choosing a factory isn’t just about price; it’s also about craftsmanship and quality assurance. Deran’s unique strength stems from its multi-faceted innovations in foaming technology.

Advanced Production Equipment

The Deran factory is equipped with modern injection molding and foaming equipment and automated production lines. The stability of the equipment ensures uniform foaming, avoiding common problems such as uneven porosity and over- or under-foaming. This level of automation also ensures consistent high quality even in large-scale production.

Integrated Foaming Process

Unlike some factories that only handle the sole or the shoe body, Deran can achieve integrated foaming of the sole and the shoe body, as well as the shoe trim and the main material. This not only improves overall comfort but also allows customers greater design freedom. For example, personalized logos and special shoe trims can be directly integrated into the foam material, rather than being attached later.

Strict Quality Testing and Certification

Deran has a comprehensive quality control process:

- Abrasion Testing: Verifies the durability of the sole by simulating wear conditions.

- Rebound Testing: Evaluates the sole’s ability to recover after being subjected to pressure.

- Environmental Testing: Ensures compliance with international standards such as REACH and CPSIA, and the absence of hazardous substances such as phthalates and formaldehyde.

These tests and certifications not only ensure product quality and safety, but also pave the way for customers to enter high-standard markets such as Europe and the United States. Differentiating from Ordinary Factories

While many small factories can produce Crocs-like shoes, they often only imitate them, lacking process control and certification support. Deran stands apart. It not only meets customers’ customization needs but also provides professional solution optimization advice, ensuring that products better suit the consumer habits of the target market.

Diverse Options for Custom Crocs Shoes and ODM/OEM Services

Customization is one of Crocs’ most attractive features, and Deran has accumulated extensive experience in this field.

Diverse Customization Options

- Shoe Style Options: From classic clogs to flip-flops and sandals.

- Sole Thickness and Foam Density: Flexible adjustment based on target market demographics (children, adults, outdoor enthusiasts).

- Color and Texture: Creative processes such as multi-color injection molding and gradient foaming are supported.

Integration of Shoe Accessories and Foam Materials

The popularity of Crocs shoe accessories, Jibbitz, allows every pair of shoes to become a vehicle for personal expression. Deran’s advantage lies in integrating shoe accessories with foaming technology, rather than simply producing external accessories. This combination makes the shoes stronger and more integrated, enhancing the product’s added value.

ODM/OEM Service Process

Deran’s service goes beyond manufacturing; it acts more like a solutions provider:

- ODM: The factory directly provides the design, and the customer simply selects and customizes the details.

- OEM: The customer provides the design, and the factory mass-produces it based on the customer’s specifications.

Regarding either model, Deran has a dedicated team responsible for every step, from sample production to mass production, ensuring smooth communication and reducing trial-and-error costs.

Successful Cases and Application Scenarios

For example, a customer wanted to launch summer Crocs sandals for children, requiring vibrant colors and safe, odorless materials. Deran achieved lightweight design through low-density foaming technology and used non-toxic, environmentally friendly raw materials. The final product was a hit with the market. This case study fully demonstrates the factory’s flexibility and expertise.

How Customers Collaborate with Deran for Custom Crocs Shoes

For customers, process and details are crucial to a successful custom collaboration.

From Requirements Communication to Sample Confirmation

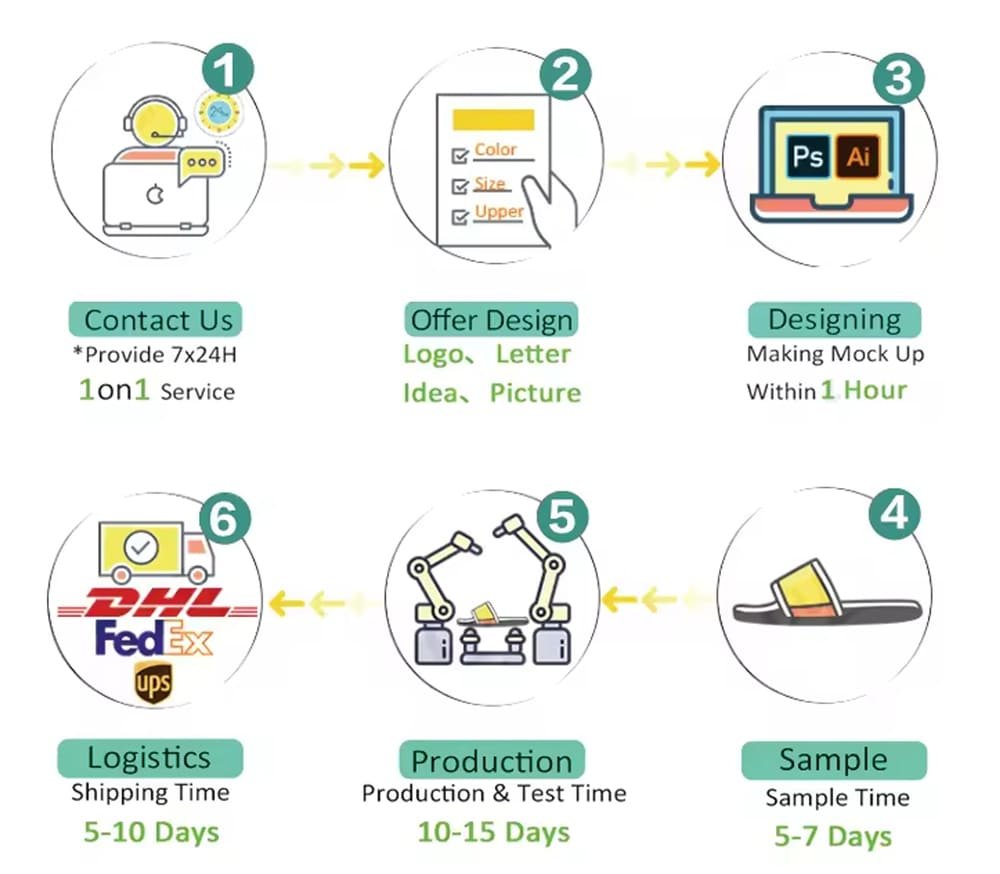

Collaboration typically begins with a requirements communication, where the customer specifies the shoe shape, color, logo placement, and other details. Deran will provide professional advice based on your needs and quickly produce samples for customer approval.

Notes on Customizing Crocs Shoes

- Logo: It is best to confirm the size and placement in advance so that they can be embedded during the foaming process.

- Packaging: Deran supports a variety of customized packaging options, including eco-friendly packaging.

- Color: Pantone color charts are provided for comparison to ensure consistent color throughout mass production.

The Impact of Foaming Parameters on Products

Different foam densities provide varying levels of comfort and durability. For example, low density is suitable for children’s shoes, while high density is more suitable for outdoor shoes. Customers can select the appropriate parameters based on their target audience before placing an order.

How to Reduce Procurement Risk

Deran has a comprehensive delivery and quality assurance mechanism:

- Delivery Control: Dedicated project managers monitor production progress in real time.

- Quality Assurance: Full or random inspections are conducted before shipment to ensure batch consistency.

- After-Sales Support: Feedback channels are provided to ensure long-term and stable cooperation.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

In today’s highly competitive Crocs customization market, simply relying on low prices is no longer enough to win long-term customer trust. Truly valuable collaboration depends on a factory’s stable foaming technology, comprehensive quality management systems, and flexible customization capabilities.

Deran is just such a factory:

- It uses advanced foaming processes to ensure comfortable, lightweight, and environmentally friendly shoes.

- It offers integrated ODM/OEM services, helping customers quickly bring their creative ideas to life.

- It undergoes international certifications and rigorous testing, ensuring easy access to high-standard European and American markets.

- It provides comprehensive customer support in communication, delivery, and after-sales service.

If you’re looking for a reliable custom croc shoes factory, Deran is a trusted partner. Leveraging its extensive expertise in foaming technology, Deran can not only help you differentiate your products but also give your brand an edge in the fiercely competitive market.