Table of contents

- Advanced production equipment and craftsmanship are the cornerstones of a top-tier manufacturer

- Strict Raw Material Selection and Quality Management System

- Strong design and R&D capabilities help differentiate the brand.

- Flexible Production and Delivery Capabilities to Meet Global Order Demand

- Perfect Customer Service and Guaranteed Long-Term Partnership

- How to Choose a Top Crocs Shoe Manufacturer Like Deran

In recent years, with the rise of casual and comfortable styles, Crocs shoes (Clogs) have evolved from functional footwear into a globally popular trendsetter. From fun children’s styles to casual adult styles and limited-edition collaborations, Crocs shoes have become a fixture in the fashion world and a must-have for everyday wear, travel, and vacations. For brands, wholesalers, and even cross-border e-commerce sellers, finding a professional and reliable Crocs shoe manufacturer is the first step to ensuring product quality and market competitiveness.

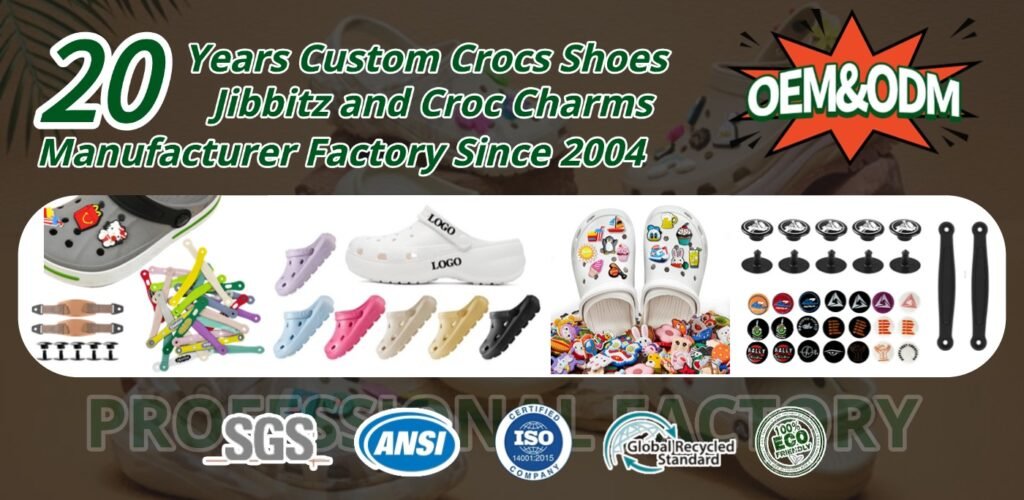

As a leading Crocs and jibbitz manufacturer, Deran has provided OEM and ODM services to markets across North America, Europe, and Southeast Asia for many years, establishing itself as a long-term, trusted partner for many international brands and large wholesalers. So, what sets Deran apart as a top-tier Crocs shoe manufacturer? Let’s take a comprehensive look at Deran’s core advantages across five key areas: production, materials, R&D, delivery, and service.

Advanced production equipment and craftsmanship are the cornerstones of a top-tier manufacturer

Advanced production equipment and exquisite craftsmanship are essential for producing comfortable, lightweight, durable, and aesthetically pleasing Crocs shoes. Compared to typical EVA slippers or casual shoes, the production process for Crocs shoes is more sophisticated, as it must balance comfort and support with aesthetic design and wear resistance.

High-precision EVA injection molding

The core of Crocs shoes lies in the foaming and injection molding of the material. Ordinary factories typically use single-color, standard foaming EVA injection molding machines, which are unable to meet the production requirements of Crocs shoes with rich colors and intricate details. Deran’s factory is equipped with multiple high-precision multi-color injection molding machines, capable of two- or even three-color integrated molding. This allows them to produce not only classic single-color shoes but also complex designs such as gradient colors and color block patterns.

For example, brand clients often request different hardness materials for the sole and upper to enhance comfort. Deran’s multi-material injection molding process allows them to precisely control the density and softness of different areas, ensuring the finished product is both lightweight and supportive.

Automated production lines improve efficiency and consistency

Many brand clients require rapid new product launches or large-volume deliveries during peak seasons. Relying on manual production lines is not only slow but also inconsistent in quality. Deran’s production facility has integrated automated feeding, injection molding, and trimming, significantly reducing manual errors.

This automation not only increases production capacity but also improves quality consistency. For example, a fully automated production line can produce tens of thousands of pairs of shoes in a single day, ensuring that each pair is consistent in weight, color, and size.

Comprehensive Quality Monitoring System

Top manufacturers not only deliver quickly but also prioritize quality control throughout the production process. Deran’s production facility incorporates in-line quality inspections, including sole thickness monitoring, color uniformity checks, hardness testing, and visual inspections.

This means that every batch of products leaving the factory has an extremely low error rate, allowing brand clients to ship products almost directly to the store without worrying about returns or complaints.

Strict Raw Material Selection and Quality Management System

The comfort and durability of Crocs shoes depend heavily on the quality of their raw materials. Many first-time cross-border sellers often overlook this point, focusing solely on the design and ignoring the potential for deformation, cracking, or odor issues caused by material differences.

Selecting High-Quality EVA and TPU Materials

As a top manufacturer, Deran understands the importance of materials. Common shoe materials include:

- High-elasticity EVA foam particles: Lightweight, wear-resistant, and non-slip, suitable for integrated sole and body molding

- TPU/TPR sole materials: Improve wear resistance and support

- Croslite™-based eco-friendly materials: Meet international environmental standards, are non-slip and wear-resistant, and are odor-resistant

Deran rigorously screens its suppliers at the source, working only with raw material factories certified by REACH, ROHS, and SGS. This ensures that every pair of shoes sold in the European and American markets will not be returned due to chemical content issues.

Multi-Level Quality Control Process

Deran adheres to a three-tiered quality management process: IQC → IPQC → FQC:

IQC (Incoming Material Inspection): All EVA and TPU pellets are tested for color, density, elasticity, and environmental performance before storage.

IPQC (In-Process Inspection): Inspectors are deployed throughout the injection molding, foaming, and cooling stages to identify issues such as bubbles and color variations.

FQC (Freight Quality Control): Random inspections are conducted according to international AQL standards, including folding and abrasion testing, and visual inspections.

This multi-step quality management process ensures that Deran’s product qualification rate remains above 99%.

International Certifications and Customer Trust

Many brands require verification of a manufacturer’s factory certifications before working with them. Deran not only holds ISO 9001 quality management system certification, but also BSCI social responsibility certification and SGS environmental testing reports. This is crucial for cross-border sellers, allowing them to directly address the compliance requirements of the European and American markets.

Strong design and R&D capabilities help differentiate the brand.

With Crocs’ increasingly competitive footwear market, simply offering standard slipper styles is no longer enough. Consumers are increasingly seeking designs with distinctive designs, unique colorways, or the ability to be customized. This is one of Deran’s strengths.

Professional Design Team and Rapid Prototyping Capabilities

Deran boasts an experienced design and R&D team capable of optimizing appearance, color combinations, and structure based on the client’s brand positioning. The design team not only uses 3D modeling software for structural design but also quickly produces 3D printed samples, allowing customers to visually understand the product’s look and feel before placing an order.

Typically, sample production is completed within 1-2 weeks of the client submitting a design concept, significantly shortening the time from idea to market.

OEM and ODM Service Capabilities

- OEM: The client provides an existing design, and Deran is responsible for production and quality assurance.

- ODM: Deran provides original designs based on market trends and client needs, providing a one-stop service from style design and mold making to full-scale production.

This flexible service model is suitable for both wholesalers with established brands and new sellers looking to quickly enter the market.

Success Story Sharing

For example, a European client wanted to launch a summer parent-child series of clogs. They required the same design for both the parent and child styles, but with different sizing and comfort requirements. The Deran team completed the design and sample creation within a week and used two-shot injection molding to create a fun color combination. Delivery was completed within a month, earning the client’s approval.

Flexible Production and Delivery Capabilities to Meet Global Order Demand

Amidst the volatile global supply chain, manufacturers’ production and delivery capabilities are crucial. Many brands face the risk of missing out on the entire sales season if they can’t secure goods on time during peak season.

Flexible Handling of Large and Small Orders

Deran can handle large orders of hundreds of thousands of pairs, as well as small trial runs for emerging brands.

- Small-batch customization: Minimum order quantity as low as 500-1,000 pairs

- Large-batch production: Monthly production capacity can reach over 500,000 pairs

This flexibility allows brands to adjust their sourcing strategies based on market conditions and mitigate inventory risk.

Fast Prototyping and On-Time Delivery

- Sample Turnaround: Typically 1-2 weeks

- Bulk Production Turnaround: 30-45 days (depending on order complexity)

- Global Logistics Support: We can offer ocean, air, or international express shipping options.

Thanks to our comprehensive production and logistics systems, Deran maintains an on-time delivery rate of over 95%.

Perfect Customer Service and Guaranteed Long-Term Partnership

Top manufacturers are more than just suppliers; they are long-term partners. Deran also excels in customer service:

Full-Process Follow-up: From design communication, sample confirmation, production scheduling, to shipping logistics, dedicated sales representatives provide follow-up throughout the entire process.

After-Sales Guarantee: If quality issues arise, we offer exchange or restocking options.

Multi-Language Support: Our English, Spanish, and Chinese service teams facilitate communication with our international customers.

Many customers who have worked with Deran for over five years describe it as a “peace of mind and reliability” manufacturer, not only because they receive the product but also because they receive ongoing supply chain support.

How to Choose a Top Crocs Shoe Manufacturer Like Deran

For brands or wholesalers looking to enter the Crocs shoe market, consider the following factors when choosing a partner factory:

- Equipment and Process: Whether the factory has multi-color injection molding and automated production lines;

- Raw Materials and Certification: Whether it uses environmentally friendly materials and has ISO, SGS, and other certifications;

- Design Capabilities: Whether it can provide ODM design and rapid prototyping services;

- Production and Delivery: Whether it can flexibly handle large and small orders and deliver on time;

- Customer Service: After-sales support and responsiveness for long-term partnerships.

Before placing an order, you can mitigate the risks of partnering with Deran through sample testing, on-site factory visits, or video inspections.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Deran has become a top Crocs shoes manufacturer because of its industry-leading production equipment, material control, design and development, flexible supply, and customer service. For brands, wholesalers, and cross-border e-commerce sellers, partnering with a top manufacturer like Deran not only ensures product quality but also gives your business a competitive edge.

If you are looking for a trustworthy Crocs shoes manufacturing partner, you might as well start by requesting samples and experiencing the comfort and quality of Deran products yourself. This will be the first step to opening a long-term cooperation.