Table of contents

- Deran’s manufacturing advantages: professional Crocs OEM/ODM factory

- Deran Custom Crocs Factory Strength: Scale, Experience, and Production Capacity

- Deran’s Advantages in Wholesale IP Crocs: Design Accuracy and Market Adaptability

- How to Choose a Reliable Crocs Custom Wholesale Factory?

- Quality inspection and factory inspection standards: ensure comfort and safety

Many people are curious: How is a pair of seemingly simple Crocs shoes made? Are its raw materials, production processes, and customization processes the same as ordinary shoes? In fact, the manufacturing process behind Crocs is far more complicated than it looks, especially the Croslite material used – a closed-cell resin material, which not only makes the shoes antibacterial, lightweight, and non-slip, but is also the core technical link in the entire production process.

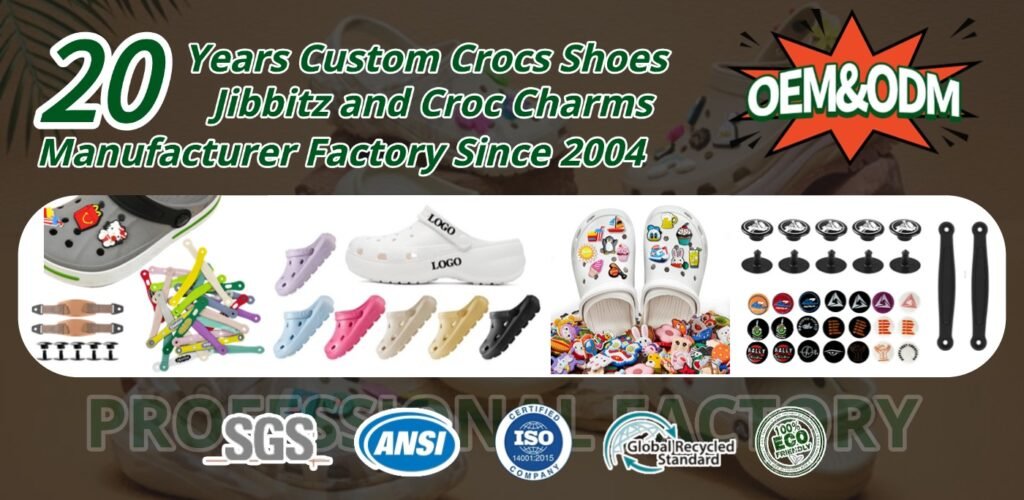

Deran’s manufacturing advantages: professional Crocs OEM/ODM factory

Deran crocs shoes manufacturer has been focusing on the manufacturing of Crocs shoes and accessories for more than 20 years. It has 20 fully automatic injection molding production lines with a monthly production capacity of 400,000 pairs and serves more than 30 overseas brand customers. We provide the following customization advantages:

Customized design support: from design drawings, proofing, mold making to mass production.

Fast delivery capability: standard regular colors can be delivered in as fast as 7 days, and customized Jibbitz can be sampled in as fast as 3 days.

Complete multi-national certifications: The factory has passed ISO9001 quality management system and BSCI social responsibility certification.

Rich cooperation cases: long-term cooperation brands include chain retailers and clothing brands in Europe and the United States.

Whether you are a start-up brand or an established footwear company, Deran can provide flexible customization and full-link services to ensure an efficient, controllable and sustainable cooperation experience.

Deran Custom Crocs Factory Strength: Scale, Experience, and Production Capacity

To evaluate whether a custom Crocs factory is worth partnering with, it’s not enough to just look at the appearance of the samples. More importantly, it needs to possess the following three fundamental capabilities:

- A long-term, stable manufacturing system

- Mature mold and materials engineering capabilities

- A quality control system that can be scaled up and replicated.

Deran has a clear advantage in these three areas.

Factory Scale and Basic Manufacturing Capabilities

Deran has a complete footwear manufacturing production line system, including:

- EVA / TPR / PU / foamed rubber injection molding lines

- CNC mold machining center

- Digital shoe last modeling system

- Automatic spraying and screen printing system

- Assembly and final inspection lines

Currently, the factory has multiple dedicated production lines for Crocs and Birkin-style shoes, with a monthly capacity of over 1.2 million pairs, supporting stable delivery from small-batch customization (MOQ 500–1000 pairs) to large-scale wholesale orders (over 100,000 pairs per style).

Mold development capabilities determine the upper limit of customization

Many Crocs OEM manufacturers can only customize colors and logos, but cannot support structural customization, shoe shape innovation, or IP styling reconstruction. This directly limits the brand’s ability to differentiate its products.

Deran has a complete mold R&D department that supports:

- Original shoe shape structure development

- Toe proportions, perforation distribution, and upper curve reconstruction

- IP character structure embedded design

- Functional structure design (thick sole, non-slip sole, arch support system)

Using a CAD + Rhino + SolidWorks 3D modeling system, Deran can complete the initial shoe shape structure model within 5–7 working days and the first mold sample within 15–20 days. This is a very fast pace in the Crocs shoe mold industry.

This means that brands can complete new product testing, market validation, and channel distribution more quickly, thereby reducing trial and error costs.

Deran’s Advantages in Wholesale IP Crocs: Design Accuracy and Market Adaptability

In recent years, IP-branded Crocs have become one of the fastest-growing subcategories in the global footwear market.

Deran possesses a systematic advantage in the customization and wholesale of IP-branded Crocs, primarily reflected in three aspects:

Mature IP accuracy, not just simple printing.

The challenge of IP Crocs lies not in “printing the image,” but in how to transform a two-dimensional image into a three-dimensional shape that conforms to the shoe’s structural proportions, while ensuring mass production stability and wearing comfort.

Deran typically performs the following steps in IP Crocs projects:

- IP Character Structural Deconstruction: Breaking down the character’s head-to-body ratio, logo elements, and identifying features.

- Shoe Fitting Modeling: Embedding IP elements into the toe, side, buckle, or 3D accessory system.

- Mass-ready Structural Verification: Ensuring the structure does not affect wearability, comfort, or durability.

- Material Color System Reproduction: Color matching based on Pantone color charts and IP standards.

Deran’s design team not only possesses experience in footwear structure but is also familiar with the copyright review process for IP-licensed products. This allows them to assist brand clients in efficiently completing style approval and revision processes, reducing the time costs associated with repeated modifications.

Wholesale-ready IP Crocs Product System Building Capability

Many IP projects fail not because of poor design, but because of a simplistic product structure, insufficient price range coverage, and an unreasonable SKU combination, leading to low channel distribution efficiency and slow inventory turnover.

In its IP Crocs wholesale projects, Deran assists clients in building a complete product matrix, including:

- Entry-level basic models: suitable for large-scale channel distribution

- Mid-range design models: for brand image display and online marketing

- High-end limited edition models: for IP fan economy conversion and premium sales

Supports:

- Adult / Children / Family models

- Flat / Platform / Non-slip sole / Outdoor models

- Standard perforated / Birkenstock slippers / Open-toe sandal construction

This systematic product capability enables brand clients to cover multiple sales scenarios within an IP collaboration cycle, rather than relying solely on a single blockbuster product.

IP Crocs Wholesale Stability and Delivery Guarantee

Once IP products enter the market, the biggest risk is often not unsellable stock, but rather supply shortages or inconsistent quality.

Deran implemented the following control mechanisms in its IP Crocs project:

- Fixed material batch management system

- Dual standard locking for color and hardness

- Mold version freeze system

- IP dedicated production line scheduling system

This ensures a high degree of control over the consistency of appearance, feel, and structure across different batches and production cycles of the same IP series, greatly reducing after-sales risks for the brand.

How to Choose a Reliable Crocs Custom Wholesale Factory?

Many brands and wholesalers, when looking for Crocs OEM/ODM factories, often only focus on price quotes, neglecting the key factors that truly determine the success or failure of long-term cooperation.

Below, I will provide a practical evaluation method from a procurement perspective.

Don’t just look at samples, look at “reproducibility”

Excellent samples do not equal excellent mass production capabilities.

Purchasing parties are advised to focus on the following when evaluating a factory:

- Can they provide multiple batch sample comparisons?

- Do they have a stable color difference control mechanism?

- Can they provide material batch testing reports?

Deran provides batch stability sample comparisons and data explanations from the initial stage of the project to help clients assess the risk of mass production consistency issues.

It is essential to confirm whether they have independent mold development capabilities.

If a factory can only use generic molds, it cannot support truly differentiated designs.

When purchasing, key confirmations should include:

- Does the company have an in-house mold workshop?

- Can the company modify shoe last proportions and structure?

- Does the company support original shoe design development?

Deran’s mold team can support development from scratch, avoiding product homogenization and price wars.

Confirm whether the company has practical experience in IP projects.

IP projects are completely different from ordinary customization, involving copyright review, image proportion reproduction, style consistency, and market tone matching.

It is recommended to inquire during purchasing:

- Do they have IP licensing project case studies?

- Are they familiar with the licensing approval process?

- Do they support structured development of IP elements?

Deran has a mature IP project execution system, which can effectively reduce the project failure rate.

Quality inspection and factory inspection standards: ensure comfort and safety

Material safety certification standards

Crocs shoes must comply with a number of international environmental and safety certifications during the manufacturing process, including:

- TÜV Rheinland material test report

- REACH Regulation EU Chemical Control Standards

- ROHS Hazardous Substance Control

- OEKO-TEX® Textile Safety Standard (applicable to shoelaces and pads)

In-process inspection items

After each process, standardized tests such as dimensional tolerance control, surface bubble/indentation inspection, and odor control (≤ Level 2) are required to ensure process stability.

Finished product inspection process

- Bending test: simulate daily walking, requiring no breakage after 3,000 bends;

- Dynamic anti-slip test: The friction coefficient on the standard test ground must be ≥0.35;

- Cold and hot alternating test: no deformation after three rounds of -20℃~45℃ cycle test;

Packaging and logistics

The finished product needs to be cleaned twice, packaged in customized packaging boxes, and marked with size, batch, certificate of conformity, test report, etc., to ensure no deformation or pollution during transportation.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

The success of Crocs shoes comes not only from its unique appearance design, but also from its high integration of material selection, manufacturing process, user experience and personalization. For jibbitz manufacturer, mastering injection molding process and mold technology is the foundation, while the control of quality details, compliance with environmental protection requirements, and the realization of user personalized needs are the key to stand out.

If you are looking for a trustworthy OEM/ODM Crocs shoe factory, please contact Deran, we will provide you with professional, one-stop solutions.