Table of contents

- The Appeal of Manufacturing in China: Why More Brands Choose Chinese Crocs Manufacturers

- About Deran: Combining Experience and Innovation as a Crocs Manufacturer

- How Are Crocs Shoes Made? — A Full Disclosure of the Manufacturing Process

- What Are the Real Advantages of Collaborating with Deran?

- Market Trends and Future Outlook: New Opportunities in the Crocs Industry

The Appeal of Manufacturing in China: Why More Brands Choose Chinese Crocs Manufacturers

China has established itself as one of the world’s most important shoe manufacturing and exporting countries. Especially in products like injection-molded shoes and EVA clog-style footwear, Chinese factories boast significant advantages in equipment capabilities, technical expertise, and delivery efficiency, making them preferred partners for many international brands.

The main reasons why Chinese manufacturing stands out include:

- Comprehensive Local Supply Chain: From raw material procurement, mold processing, injection molding to printing, packaging, and export logistics, all steps can be completed domestically, greatly reducing communication and time costs.

- Flexible Production and Quick Response: Chinese manufacturers can easily handle small batches, multiple SKUs, mixed colors, and complex orders, meeting various market stages and brand testing needs.

- Experienced Workforce and Advanced Equipment: With a large number of skilled workers and wide application of automated injection molding equipment, product quality is stable, and production efficiency is high.

Against this industrial backdrop, experienced companies like Deran, with two decades of manufacturing expertise, can quickly respond to client needs and serve as ideal crocs manufacturers and crocs wholesale suppliers.

About Deran: Combining Experience and Innovation as a Crocs Manufacturer

Founded in 2005 and located in Jinjiang, Fujian Province, Deran specializes in OEM and ODM production of slippers, clog-style shoes, plush slippers, Crocs-style shoes, and Jibbitz shoe charms. With a 4,000-square-meter factory, four injection molding production lines, a dedicated shoe charm assembly workshop, and a mold development center, Deran’s monthly output reaches 400,000 pairs, capable of supporting medium to large volume orders consistently.

Key strengths include:

- 20 Years of Manufacturing Experience: Well-versed in product structure, molding technology, and custom processes

- Strong Development Capability: Independently developed over 300 design styles, catering to diverse customer needs

- Flexible Cooperation: Supports minimum orders as low as 20 pairs, ideal for startups and small brands

- Professional International Trade Team: Provides 7×24-hour communication to ensure efficient project coordination

- Rich International Client Experience: Familiar with quality and compliance standards of markets in Europe, America, the Middle East, and Southeast Asia

Deran is more than a manufacturer; it’s a trusted strategic partner behind your brand’s success.

How Are Crocs Shoes Made? — A Full Disclosure of the Manufacturing Process

As a professional crocs manufacturer, Deran strictly follows standardized production processes to ensure every pair of shoes is not only stylish but also comfortable and durable. The key stages include materials, molds, customization, and quality control:

Material Selection and Structural Configuration

The comfort of Crocs shoes heavily depends on material choice and structural parameters. Deran offers various materials, including EVA, TPR, TPU, and Croslite-type foamed materials, balancing softness, resilience, and durability.

Clients can freely customize:

- Shoe body density and sole hardness

- Material grade and foot feel style

- Exact Pantone color matching

Deran tailors different product levels and visual effects based on target markets and consumer groups.

Mold Development and Injection Molding

Molds are the core determinant of shoe shape quality. Deran has an in-house mold design and processing team enabling fast modeling and sample production:

- Typically completes initial modeling within 1 hour and sampling within 3–5 days

- Utilizes high-precision injection molding machines to ensure uniform shoe structure, sharp edges, and consistent weight

- Employs adjustable temperature control technology in molds to maintain process stability and reduce deformation

Clients may choose from Deran’s existing molds or develop exclusive shoe shapes, enjoying flexible customization.

Personalized Details Implementation

Personalization of Crocs often focuses on shoe charms, straps, and brand logos. Deran can fulfill:

- Jibbitz shoe charms with brand logos, 3D shapes, glitter, glow-in-the-dark, metal finishes, and more styles, suitable for kids’, couples’, and fashion lines

- Heel straps and uppers with hot stamping, silk-screen printing, laser engraving, and embossed logos; heel straps can feature functional buckles or soft rubber accents

- Accessory assembly with dedicated stations ensuring precise placement and durability

Deran offers complete visual design consulting to translate brand visions into high-fidelity physical products.

Finished Product Inspection and Packaging

To guarantee quality, multiple layers of inspection are implemented:

- Raw material compliance with environmental and safety standards;

- Mold consistency and injection appearance checks;

- Product dimensions, color accuracy, weight, and elasticity tests;

- Functional tests including slip resistance, abrasion resistance, and structural strength.

Finished product qualification rate exceeds 99%, with support for third-party quality audits.

Packaging options include custom color boxes, shrink wraps, kraft paper, hang tags, and branded stickers, facilitating retail and e-commerce distribution.

What Are the Real Advantages of Collaborating with Deran?

Deran’s core competitive strengths lie in flexibility, professionalism, and comprehensive service capabilities. Key client benefits include:

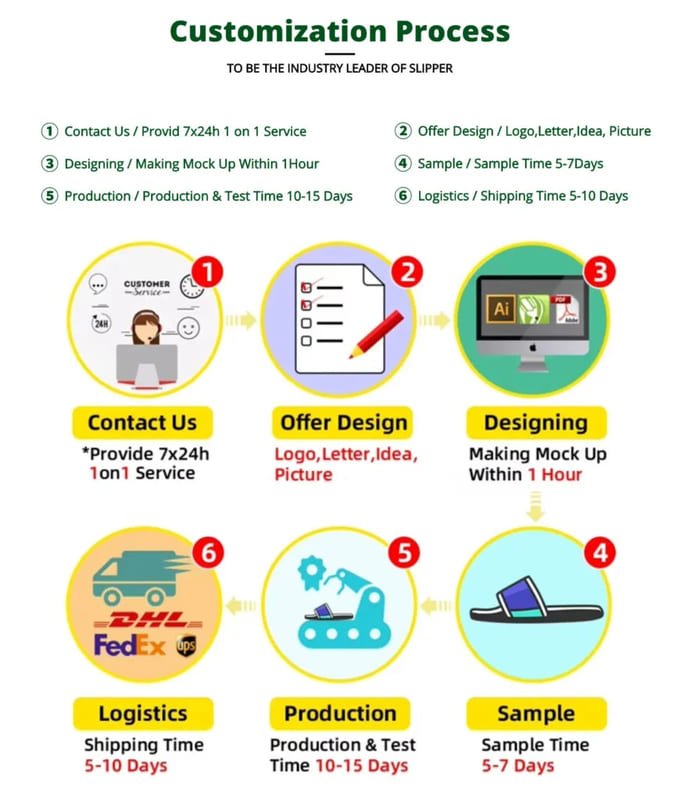

One-Stop OEM & ODM Customization Process

From concept to delivery, Deran offers end-to-end services:

| Consultation & Design | Submit sketches, logos, colors, ideas | Real-time response, modeling within 1 hour |

| Sample Production | Sample making and revisions | 5–7 days |

| Mass Production | Injection, assembly, quality control | 10–15 days |

| Export Logistics | Packaging, shipping, customs clearance | 5–10 days |

Understanding each brand’s unique development stage, Deran offers flexible MOQs, with minimum order quantity as low as 20 pairs, enabling low-risk trial sales.

Rapid Sampling Capability

Fastest sample turnaround is only 3 days, perfect for:

- New product testing

- Seasonal promotions

- Online crowdfunding or small brand launches

This fast-response mechanism helps clients improve market agility.

Environmental Compliance and Export Certifications

Deran emphasizes green manufacturing and adheres to international standards. Upon client request, certifications include:

- REACH compliance

- ROHS environmental declarations

- OEKO-TEX® harmful substance tests

- TÜV certification

These credentials ensure smooth export to major global markets.

Brand Visual Support Services

An internal design support team helps clients optimize product presentation:

- Logo placement advice and structural adaptation diagrams;

- Coordination of shoe charm and overall color schemes;

- Packaging, hang tag, and display design suggestions.

Every design detail is translated into commercially viable, market-ready products.

Market Trends and Future Outlook: New Opportunities in the Crocs Industry

Crocs-style products continue to evolve, combining functionality, casual style, and playfulness, becoming an essential part of current trendy footwear.

Trend 1: The Rise of Comfortable Aesthetics

Consumers increasingly demand shoes that blend comfort with style. Crocs achieve this through:

- Soft foam materials

- Playful, customizable accessories like Jibbitz charms

- Vibrant and varied color palettes

This appeal spans all age groups and suits multiple scenarios such as summer outings, home wear, and vacations.

Trend 2: Rise of Niche Brands and Demand for Personalization

E-commerce and social media have empowered numerous small footwear brands that seek small-batch, fast-response, uniquely styled supply chains. Deran actively serves such independent brands, offering tailored manufacturing solutions.

Trend 3: Sustainability and Environmental Responsibility

Research and application of renewable EVA and bio-based TPU materials are maturing. Deran is investing in sustainable manufacturing practices through material selection, energy management, and recyclable packaging to meet green supply chain demands.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

If you are looking for a Crocs shoe cooperative factory with professional experience, environmental protection concept, flexible manufacturing and stable delivery, Deran will be your ideal crocs manufacturer and crocs wholesale supplier. From the beginning of the story to the landing of the product, Deran is always willing to be a solid backing for your brand growth.