Table of contents

Crocs consumers in the UK are highly diverse. Young people are drawn to bright colors and creative patterns, while middle-aged individuals prioritize comfort and practicality. Certain occupational groups (such as those in the hospitality, healthcare, and gardening sectors) value Crocs’ durability, slip resistance, and easy cleaning. Furthermore, mass-customized Crocs are becoming increasingly popular for team activities, school clubs, and brand marketing campaigns.

The rise of personalized footwear is driven not only by fashion trends but also by shifting consumer attitudes. Today’s consumers are no longer satisfied with standard footwear found on store shelves; they want each pair of shoes to reflect their individuality, even becoming an extension of their identity and lifestyle. This trend has created a higher demand in the UK market for Crocs manufacturers with high-quality customization capabilities.

Deran’s Core Strengths as a Top Custom Crocs Manufacturer

Deran croc wholesale suppliers has a solid foundation and extensive experience in the global custom Crocs manufacturing industry. Its strengths lie not only in production capacity and technology, but also in its deep understanding of customer needs and its flexible response.

First and foremost, Deran possesses extensive international production and export experience. Long-term collaboration with clients from diverse markets, including Europe, North America, and Asia, has enabled Deran to navigate diverse national standards, cultural preferences, and trade regulations with ease. This means smoother collaboration for UK buyers and reduced cross-border communication barriers.

Secondly, Deran has over two decades of expertise in the production and manufacturing of Crocs and accessories, particularly in areas such as Jibbitz trims, upper patterns, and sole wear resistance. Whether creating a unique limited-edition colorway or mass-producing Crocs with a corporate logo, Deran offers a stable and controllable production process.

Deran rigorously selects environmentally friendly materials such as EVA and TPU for its raw materials, and obtains international environmental and safety certifications such as ISO, REACH, and OEKO-TEX. This ensures that the finished product is not only comfortable and durable, but also complies with environmental regulations in the UK and EU markets. This is particularly important for buyers seeking to sell custom Crocs to multiple European countries.

Deran is equipped with high-precision CNC mold processing equipment and advanced multi-color injection molding machines, enabling the creation of highly complex patterns and structural designs. The company can flexibly switch between mass production and small-batch customization, allowing buyers to quickly test market response and rapidly expand production capacity if the product becomes popular.

Analysis of the Process and Procedures for Customizing Crocs

Achieving a high-quality pair of customized Crocs involves more than simply changing the color and logo; it involves a complete and professional process from design to delivery.

The first step is the design phase. Deran will conduct in-depth discussions with clients to clarify details such as the target audience, design style, color scheme, and accessory combinations. The design team then creates 3D renderings to ensure that clients can visually visualize the finished product before production begins.

The second step is material selection. EVA is the primary material for Crocs uppers, offering lightweight, waterproof, and wear-resistant properties. TPU, commonly used in soles and accessories, offers increased elasticity and durability. For Jibbitz accessories, Deran also offers custom solutions in various materials, including soft rubber, hard plastic, and metal, to suit different budgets and applications.

The third step is mold production and color matching. Mold precision directly impacts the aesthetics and comfort of the shoe. Deran uses CNC precision machining equipment to ensure every detail meets design requirements. Regarding color matching, Deran’s color matching team can accurately reproduce customer-specified colors based on the international Pantone color chart, ensuring that color variations between batches are within acceptable limits.

The fourth step is injection molding and accessory installation. This step requires precise temperature and pressure control to ensure the upper and sole are integrally molded and structurally stable. Accessory installation requires a secure fit without compromising aesthetics. Deran’s workers select the most appropriate fixing method based on the upper design.

The fifth step is finished product inspection and shipping packaging. Each pair of shoes undergoes quality inspections, including visual inspection, dimensional measurement, and bending resistance testing, to ensure that the product is flawless upon delivery to the customer. Deran offers a variety of packaging options, including individual shoe boxes, reusable bags, and bulk export cartons, to meet the needs of various sales channels.

How to Work with Deran for Custom Crocs

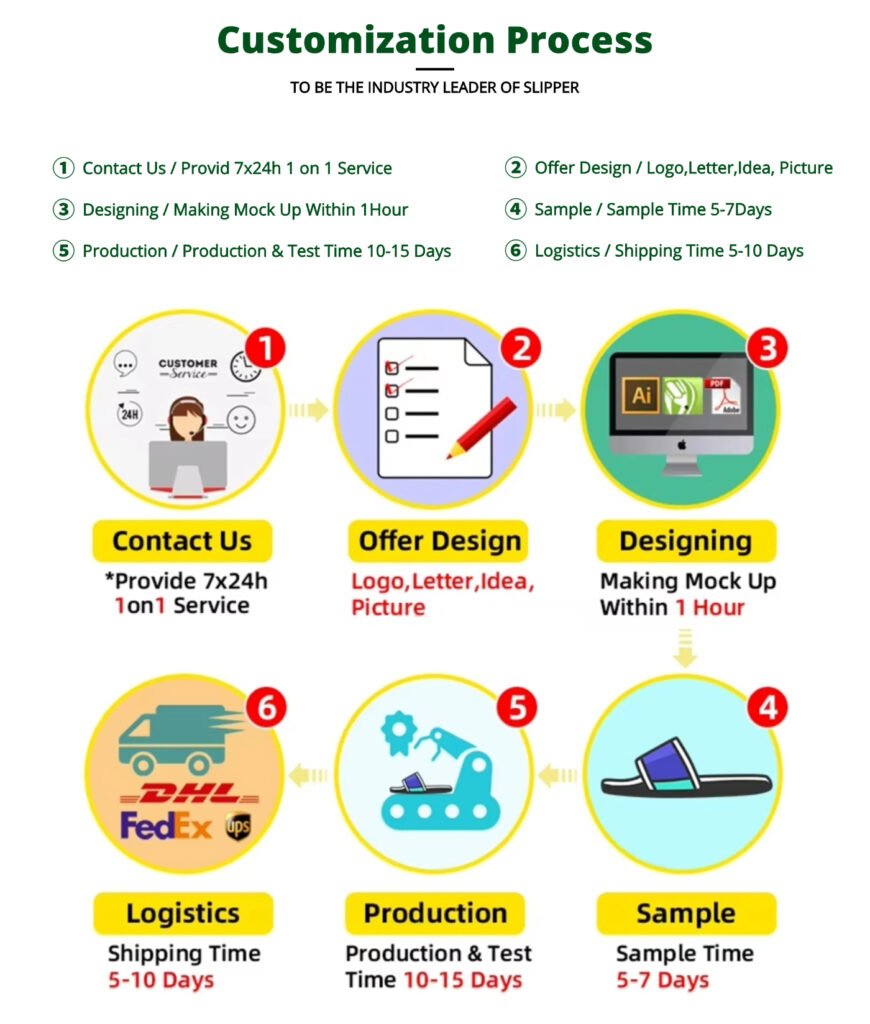

The Deran process is highly transparent and efficient, making it particularly suitable for UK buyers.

First, the process involves confirming requirements and creating samples. Customers can send Deran their design drawings, logo files, and color requirements via email or video conferencing. The factory will produce samples within 3-5 days and ship them to the customer for approval.

After confirming the samples, the buyer will select the appropriate style, color, and accessories. Deran offers a variety of basic shoe styles, dozens of standard colors, and hundreds of Jibbitz styles. The company can also custom-make custom designs.

During the production process, Deran regularly updates the production progress, including photos and videos of mold fabrication, raw material preparation, and injection molding, so customers can stay informed. The production lead time for large quantities is generally 20-35 days, depending on the order quantity and complexity.

Deran offers shipping options including sea, air, and express delivery. Deran is familiar with UK import duties and customs clearance procedures, helping customers avoid unnecessary delays and costs. Payment and after-sales service are also flexible, supporting multiple international payment methods and offering a return and exchange guarantee for quality issues.

Key Considerations When Choosing a Custom Crocs Manufacturer

For UK buyers, choosing a reliable custom Crocs manufacturer is more than just price.

First, consider certifications and compliance. The UK and EU have strict safety and environmental standards for footwear. If a manufacturer cannot provide certifications like REACH and OEKO-TEX, their products may face import risks.

Second, consider quality and durability. Although Crocs are casual shoes, they have certain requirements for comfort, slip resistance, and wear resistance. Durability is especially important for shoes used in large quantities for team or corporate events.

Production lead times and supply chain stability are also crucial considerations. Cross-border sourcing involves shipping time, and if a factory is unable to deliver on time, it can impact entire sales or event plans.

Furthermore, the degree of customization and personalized design capabilities are key indicators of a manufacturer’s performance. A quality manufacturer not only reproduces customer designs but also provides suggestions for improvements, enhancing the aesthetics and practicality of the finished product.

Deran’s Additional Value and Support for Customers

In addition to high-quality custom Crocs, Deran offers a range of additional value and support services to UK customers.

For example, OEM/ODM customization capabilities allow us to not only produce customer-specified styles but also develop entirely new shoe silhouettes and accessories from scratch. For UK customers seeking branded products, this means they can launch completely unique products on the market.

For corporate clients, Deran offers bulk solutions for team culture shoes, gift shoes, and commemorative shoes, with designs and packaging that reflect the event theme and corporate image.

For cross-border logistics, Deran has extensive experience in UK customs clearance and can help clients handle all shipping documents and procedures, ensuring a smooth delivery process.

Deran even offers practical marketing advice to clients, such as creating creative photos of their custom Crocs for social media or setting up interactive experience zones at events to attract more attention.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Overall, Deran’s popularity among UK buyers stems not only from its consistent product quality and customization capabilities, but also from its demonstrated efficiency and reliability in cross-border collaborations.

As UK consumers’ demand for personalized and eco-friendly footwear continues to grow, the market for custom Crocs will only grow. For UK businesses, event planners, and even individual entrepreneurs, now is an opportune time to enter this niche market.

If you’re looking for a custom jibbitz manufacturer that provides high-quality, unique designs, and on-time delivery, Deran is undoubtedly a trustworthy choice.