What are Crocs? ——A pair of shoes that are popular all over the world

In the early 21st century, a pair of seemingly “ugly and cute” shoes quickly swept the global fashion world, and that was Crocs. This pair of shoes was originally designed for activities on boats. It uses a unique closed-cell resin material, Croslite™, which not only has good anti-slip properties, but also has extremely high comfort, lightness and antibacterial properties. In 2002, Crocs made its debut in Colorado, USA. In just a few years, its sales exceeded 100 million, becoming one of the most popular casual shoes in the world.

The most representative design of Crocs shoes is the dense ventilation holes on the forefoot, the reversible shoelaces on the heel, and the one-piece molded shoe body. These designs not only make Crocs both comfortable and functional, but also become a unique cultural symbol. Today, from children to the elderly, from nurses to chefs, from students to celebrities, Crocs is no longer just a functional shoe, but also a way to express personality and attitude towards life.

According to Statista data, by the end of 2023, Crocs’ global annual sales will reach nearly US$3.8 billion, covering more than 90 countries, with annual sales exceeding 120 million pairs. Its explosive growth is inseparable from the help of global manufacturers, especially high-quality OEM/ODM partners from China. Among the many manufacturers, Deran crocs manufacturer is undoubtedly the most representative and competitive one.

Table of contents

- What are Crocs? ——A pair of shoes that are popular all over the world

- Why choose Crocs shoes made in China?

- Deran: China’s leading OEM/ODM manufacturer of Crocs shoes and crocs charms

- Crocs shoes made by Deran: product advantages and technical highlights

- Complete analysis of the production process of customized Crocs shoes

- Deran factory strength display: equipment, certificates and global customer trust

Why choose Crocs shoes made in China?

Many international brands choose China as their production base, and Crocs is no exception. Why are Crocs shoes made in China so popular? Not only because of “cheap”, but also because of the extremely high cost performance and highly flexible production capacity.

Mature industrial chain system

China has a complete and mature footwear manufacturing industry chain. From EVA/TPU raw materials, molds, injection molding, processing to packaging and logistics, almost all links can be completed in the same region. For example, Jinjiang, Fujian, Wenzhou, Zhejiang, Dongguan, Guangdong and other regions have gathered a large number of excellent footwear manufacturers, forming a strong synergy effect.

Advanced equipment and process capabilities

Compared with manufacturing in developing countries, China has obvious advantages in automation equipment, injection molding machine precision, mold research and development, EVA/TPR foaming technology, etc. Especially in Crocs-type injection molding slippers, domestic head factories can reach the international first-line level in molding accuracy, softness control, color stability, etc.

Highly flexible customization capabilities

International brands or buyers are increasingly favoring small-batch, diversified, and fast-delivery production models. Chinese factories usually have flexible production lines and experienced design/R&D teams that can quickly respond to the full process requirements from design to proofing, from raw material allocation to final shipment.

Controllable quality and compliance capabilities

Top manufacturers are usually equipped with independent quality control teams and can pass international certifications such as BSCI, SEDEX, TÜV, SGS, etc. to ensure that products meet the requirements of the European and American markets for environmental protection, safety, quality and other multi-dimensional standards.

Among them, Deran is a model manufacturer in the Chinese custom croc shoes manufacturing industry that integrates quality, innovation, and service.

Deran: China’s leading OEM/ODM manufacturer of Crocs shoes and crocs charms

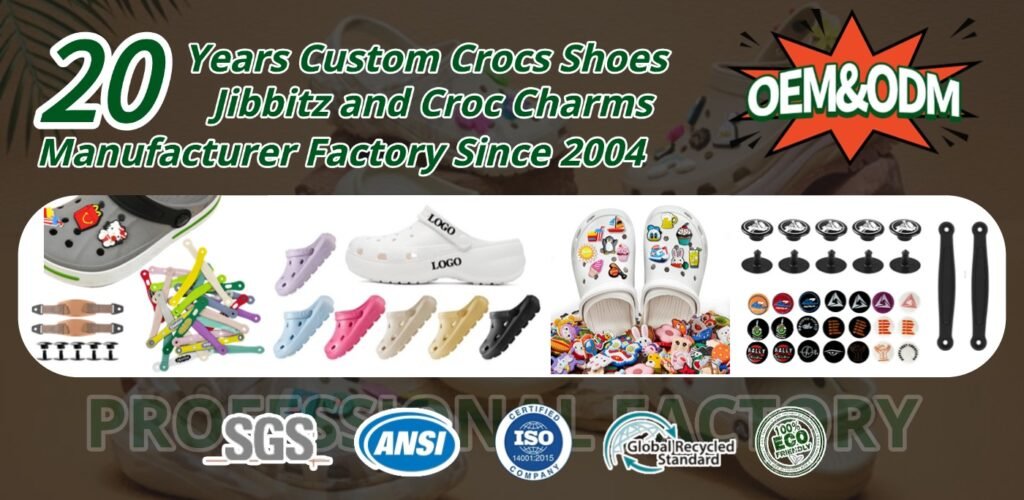

Deran is a factory specializing in the design and production of EVA injection shoes, Crocs-style hole shoes, and matching crocs charms (such as Jibbitz fasteners). Headquartered in Quanzhou, Fujian, it has more than 20 years of experience in shoe production and has established long-term cooperative relationships with many global shoe brands.

Focus on Crocs category, precise positioning

Unlike the general shoe factory with mixed product lines, Deran has been deeply engaged in Crocs products for many years. The technical team has long focused on core issues such as EVA foam density control, TPR sole compound, and matching of uppers and decorative parts. While improving technology, it is also familiar with market trends, and responds very quickly from design to proofing.

OEM & ODM full coverage service

Deran can not only provide OEM services for customer drawings or samples, but also has a professional design team to customize shoe types, colors, crocs charms, packaging and other ODM customization services for customers, meeting brand building needs in one stop. The brands that have cooperated cover markets such as the United States, Canada, France, and Japan, with a high repurchase rate.

Flexible production and small order fast return mechanism

Facing fast-response markets such as cross-border e-commerce and live streaming, Deran has the ability to order small batches (such as 300-500 pairs), fast proofing in 7-10 days, and batch delivery in 15-25 days, which is very flexible and reduces customer inventory and financial pressure.

Professional team, efficient response

The company has a foreign trade, design, and production collaboration team of more than 30 people, who can communicate in fluent English. From technical specifications to export customs clearance, the whole process can be seamlessly connected to reduce communication costs.

Crocs shoes made by Deran: product advantages and technical highlights

Crocs shoes seem simple, but in fact they have extremely high requirements for comfort, materials, and safety. Deran has made unique breakthroughs in multiple dimensions.

Material upgrade: EVA+TPU composite material, light and durable

The EVA raw material used by Deran has passed environmental certifications such as ROHS, REACH, and OEKO-TEX to ensure harmlessness to the human body. The foaming density is controlled between 0.3~0.6g/cm³, so that the shoe body remains light while maintaining support. Some high-end models also add TPU material to enhance elasticity and wear resistance, which is especially suitable for outdoor and daily wear.

High mold precision, fit the foot shape

The company uses CNC machining centers to make aluminum alloy molds, and the shoe body has smooth lines, neat edges, and no flash. The mold error is controlled within ±0.1mm, and the shoe structure is more suitable for the foot shape of Asian and European and American users.

Comfortable and functional

Crocs shoes produced by Deran are optimized through ergonomic data research on the sole support structure and the position of the ventilation holes to make them more comfortable to wear; at the same time, customized models with anti-slip, oil-proof and anti-bacterial functions are developed for chefs, hospitals and other types of workers.

Rich creative design of shoe decorations

In addition to the basic shoe body, Deran has also developed more than 300 Jibbitz decorative buckles, including cartoons, animals, brand logos, 3D dolls and other series, providing customers with optional or customized products to enhance the IP attributes of the product.

Complete analysis of the production process of customized Crocs shoes

How is a pair of high-quality Crocs shoes born? Deran provides a complete, transparent and traceable customized production process.

Demand communication and design confirmation

Customers provide sketches, samples or reference links, and the Deran design team will provide professional advice and draft plans within 1-3 days to assist customers in selecting materials, structures, colors and other details.

Mold development and sample production

After confirming the design, enter the mold stage (7-10 days), and the crocs charms matching plan can be prepared synchronously, and the sample production cycle is controlled within 12 days.

Raw material procurement and color matching

All EVA/TPU materials are from well-known domestic material manufacturers, and the batching room is equipped with color mixing equipment to ensure the color consistency of mass production.

Injection molding and crocs charms assembly

Automatic injection molding machine + manual quality inspection, each pair of shoes is manually trimmed, polished, and tested; the crocs charms are manually installed and then go through the QC process again.

Packaging and shipment

Customers can customize packaging (tag/bag/color box), provide scanning code tracking, and flexibly respond to various trade methods such as FOB/CIF/DDP.

The entire process is standardized and transparent, and records can be checked at each stage, so that customers can understand the progress and status in real time.

Deran factory strength display: equipment, certificates and global customer trust

Deran has more than 4,000 square meters of standardized factory workshops, equipped with advanced equipment and a complete management system, and is a designated cooperative manufacturer for many brands.

Production equipment: 20 EVA/TPU injection molding machines, 2 sets of mold CNC processing centers, UV printing equipment, embossing/punching machines, etc.

Testing system: There is an independent quality inspection room equipped with sole wear tester, yellowing resistance tester, tensile tester, hardness tester, etc.

Qualification certification: Passed BSCI, ISO9001, TÜV Rheinland certification, and some products have obtained SGS and REACH reports.

Customer case: Long-term cooperative brands include European and American local footwear brands, e-commerce platform sellers, animation IP joint customization companies, etc., and customer satisfaction has been maintained at more than 95% for a long time.

Not only that, Deran also participates in industry exhibitions such as the Canton Fair, FFANY American Shoe Show, and Hong Kong Global Sources every year to continue to establish stable connections with global customers.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

The continued popularity of Crocs shoes is notaccidental. It represents the contemporary people’s pursuit of a relaxed, comfortable and personalized life. Choosing an excellent Crocs manufacturer is the first step for the brand to succeed.

As a leader in China’s Crocs shoe manufacturing industry, Deran has won the trust and cooperation of many global brands with its professional manufacturing capabilities, flexible customization services, and strong design and research and development capabilities.

Whether you are a cross-border e-commerce brand looking for OEM cooperation, or want to create a hole shoe product with a personalized IP co-branding, Deran can provide you with a one-stop solution from design, production to delivery.

Now, contact Deran and start your Crocs shoe brand journey!