In recent years, Crocs shoes have set off a “hole shoe craze” in the global consumer market due to its comfort, fun and strong brand recognition. Whether it is street fashion, fashion bloggers, or parent-child families and sports enthusiasts, they all have different forms of love for Crocs. As consumers’ pursuit of personalization and brand customization continues to rise, more and more emerging brands, independent designers, e-commerce sellers, and IP parties are turning to professional Crocs OEM&ODM manufacturers to customize their own Crocs products.

But choosing a manufacturer is not easy. An ideal Crocs customization partner must not only have professional shoemaking technology and equipment, but also have full-process project management capabilities, efficient development response, rich material and accessories supply chain, and “integrated manufacturing capabilities” that can help customers quickly implement product ideas.

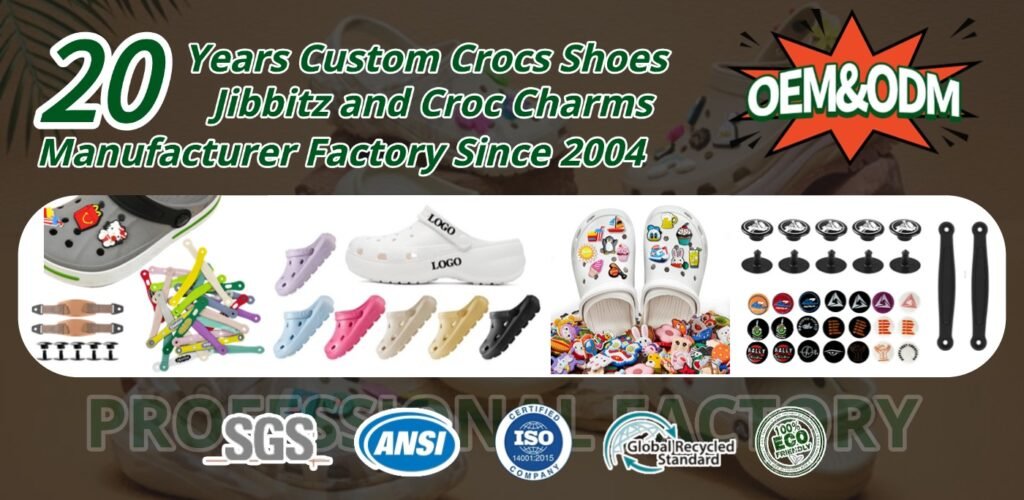

In this context, Deran, as a crocs manufacturer that has been deeply involved in the footwear manufacturing industry for many years, has become the preferred partner for the production of Crocs shoes and accessories for many brands around the world with its leading OEM&ODM customization capabilities. This article will provide you with an in-depth analysis of Deran’s full-process services, technical advantages and cooperation cases in the field of Crocs customization, helping you find a trustworthy manufacturer partner.

Table of contents

- Who is Deran? Leading Crocs Customization Manufacturer

- Analysis of the whole process of Crocs customization: every step from design and proofing to bulk delivery

- Why choose Deran: Six core advantages help brand success

- Deran customized service case sharing: How to create a million-level hot product for customers?

- Crocs shoe accessories customization: How do Jibbitz, shoe buckles, and back straps improve brand recognition?

- Common OEM & ODM problems and solutions

Who is Deran? Leading Crocs Customization Manufacturer

Deran is a professional footwear manufacturing factory located in a major manufacturing town on the coast of China. Since its establishment, it has focused on the design and production of casual shoes made of EVA, TPR, TPU, PVC and other materials. It is particularly good at OEM and ODM services for lightweight and comfortable shoes such as Crocs-type hole shoes, flip-flops, beach sandals, and home slippers.

Overview of factory strength:

- It has a modern production workshop and mold development center of more than 4,000 square meters.

- Equipped with 4 efficient automatic injection molding production lines.

- It can deliver more than 8 million Crocs product orders each year.

- It has a product design department, a proofing laboratory and a quality control center to support rapid sample feedback and multiple rounds of testing and verification.

- The team is experienced and has served cross-border brands, e-commerce brands and chain retailers in many European, American, Japanese and Korean markets.

In addition, Deran pays special attention to environmental protection and international standards. It has passed ISO9001 quality management certification and BSCI factory audit. Some materials have passed OEKO-TEX®, REACH, ROHS and other environmental standards testing, providing reliable guarantee for regulatory compliance for European and American brand customers.

Analysis of the whole process of Crocs customization: every step from design and proofing to bulk delivery

Unlike general shoe factories, Deran adopts a “project-based” operation mode in the OEM&ODM process of Crocs products, that is, with the product development manager as the main line, connecting the entire process from creative sketches to terminal delivery into an efficient and controllable customized closed loop.

Product Creative Docking

Customers provide preliminary sketches, design intentions or reference objects, and the Deran team evaluates feasibility and provides material, structure, and molding suggestions.

Mold and sample development

The internal mold department quickly opens molds according to design drawings or existing models (supports private mold/public mold development), and makes sample patterns. Generally, the first round of sample feedback is completed within 7 days.

Material and accessories selection

Provide a variety of EVA, TPU, and rubber combination solutions, support multi-color matching, and environmentally friendly material selection. For shoe accessories, Jibbitz shoe buckles, shoe back straps, upper logos, etc. can be customized.

Try-on test and modification optimization

The samples are submitted to the customer for confirmation and wearing test, and structural adjustments or material replacements are made based on feedback to ensure that the final product meets market demand.

Bulk production and quality inspection control

After confirming the samples, the factory starts batch production, strictly conducts quality inspections in accordance with AQL standards, and is equipped with metal detectors, anti-slip tests, pressure tests and other procedures to ensure that each pair of shoes meets international sales standards.

Packaging, transportation and customs clearance coordination

Support customized color boxes, tags, and instructions. With an experienced export transportation team, we assist customers in customs declaration and customs clearance document preparation, and one-stop worry-free delivery.

Why choose Deran: Six core advantages help brand success

Rich manufacturing experience: More than 20 years of focus on lightweight shoe manufacturing, understand structure, market, design, and can quickly grasp customer needs.

Highly flexible customization capabilities: Whether it is a 1,000-pair trial order for a startup brand or an e-commerce platform brand with an annual shipment of millions, Deran can flexibly allocate production capacity to cope with different customer volumes.

Fast proofing response: Samples are delivered within 7 days to meet the fast-paced market rhythm.

International environmental protection standard guarantee: REACH, ROHS, OEKO-TEX® material options help customers to enter the European and American markets.

Full-chain service closed loop: From creativity to mass production, from packaging to export, the whole process is controlled by itself, reducing communication costs and time costs.

Rich shoe accessories support: It can be matched with customized Jibbitz shoe buckles, PVC stickers, back letters, etc., to make the brand memory point more prominent.

Deran customized service case sharing: How to create a million-level hot product for customers?

Take a trendy IP brand in Europe and the United States as an example. Its initial investment was only 5,000 pairs of customized Crocs shoes. Deran designed exclusive molds and shoe buckle accessories based on its cartoon image. Through 15 days of proofing and 30 days of delivery, it helped the customer successfully set off a trend in the TikTok community. In the end, the annual orders exceeded 800,000 pairs, and the cumulative sales exceeded 12 million US dollars.

The success of such cases is not accidental, but stems from Deran’s in-depth cooperation in the following aspects:

- Customized PVC shoe accessories for IP patterns, which perfectly blend with the shoe body style.

- Cooperate with customers to develop co-branded packaging boxes and tags to enhance product integrity.

- Provide a flexible scheduling mechanism in terms of delivery time to help customers flexibly replenish stocks.

Crocs shoe accessories customization: How do Jibbitz, shoe buckles, and back straps improve brand recognition?

Today, Crocs is no longer just a “shoe”, but a wearable content display platform. Personalized shoe accessories have become one of the cores of brands to attract consumers and create UGC communication content.

Deran provides the following shoe accessories customization services:

- Jibbitz shoe buckle: PVC, TPU injection molding process, supports small batch customization, and the pattern is three-dimensional and full.

- Letter customization on the back of the shoe: The letters can be laser engraved/silk-screened, and the colors can be customized, which is suitable for family parent-child customization.

- Logo and color stickers on the upper: thermal transfer, drip molding, voltage and other methods to enrich the brand display method.

These accessories not only add visual highlights to the product, but also serve as the starting point for consumers’ secondary creation and social communication, greatly improving the brand user stickiness.

Common OEM & ODM problems and solutions

What to do if the minimum order quantity is high?

Deran supports a minimum order quantity as low as 1,000 pairs, which is suitable for new brands to test the market.

What to do if you can’t draw?

Provide template design services, customers only need to provide inspiration and reference pictures, and Deran can complete the design deepening.

Is the mold cost too high?

The public mold sharing mechanism reduces the initial mold investment, and the subsequent brand can be transferred to private mold exclusive.

What to do if the proofing is slow?

Deran promises to complete the sample within 7 days, and urgent samples can be shipped within 3 days.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Crocs is no longer just a synonym for comfortable shoes, but has become a carrier of brand culture. As consumers’ personalized needs continue to upgrade, choosing a professional, efficient and creative OEM & ODM cooperative manufacturer will be the key to whether a brand can stand out.

With its profound manufacturing background, rapid response capabilities and global vision, Deran croc wholesale suppliers has helped many brands achieve a successful transition from inspiration to product, from small batches to large-scale production. If you are considering launching your own Crocs customized products, let Deran be your trusted starting point for cooperation – starting with a pair of shoes and starting a new journey for the brand.