In the current era of increasing segmentation of consumer brands and increasingly fierce global markets, a successful footwear brand needs not only creative design concepts, but also solid and reliable manufacturing partners. From product development to finished product delivery, OEM & ODM manufacturers play a pivotal role in brand building. Especially in the category of slippers, which seems simple but is extremely sensitive to comfort, craftsmanship and cost, an experienced manufacturer with one-stop solution capabilities is a strong backing for the rise of brands.

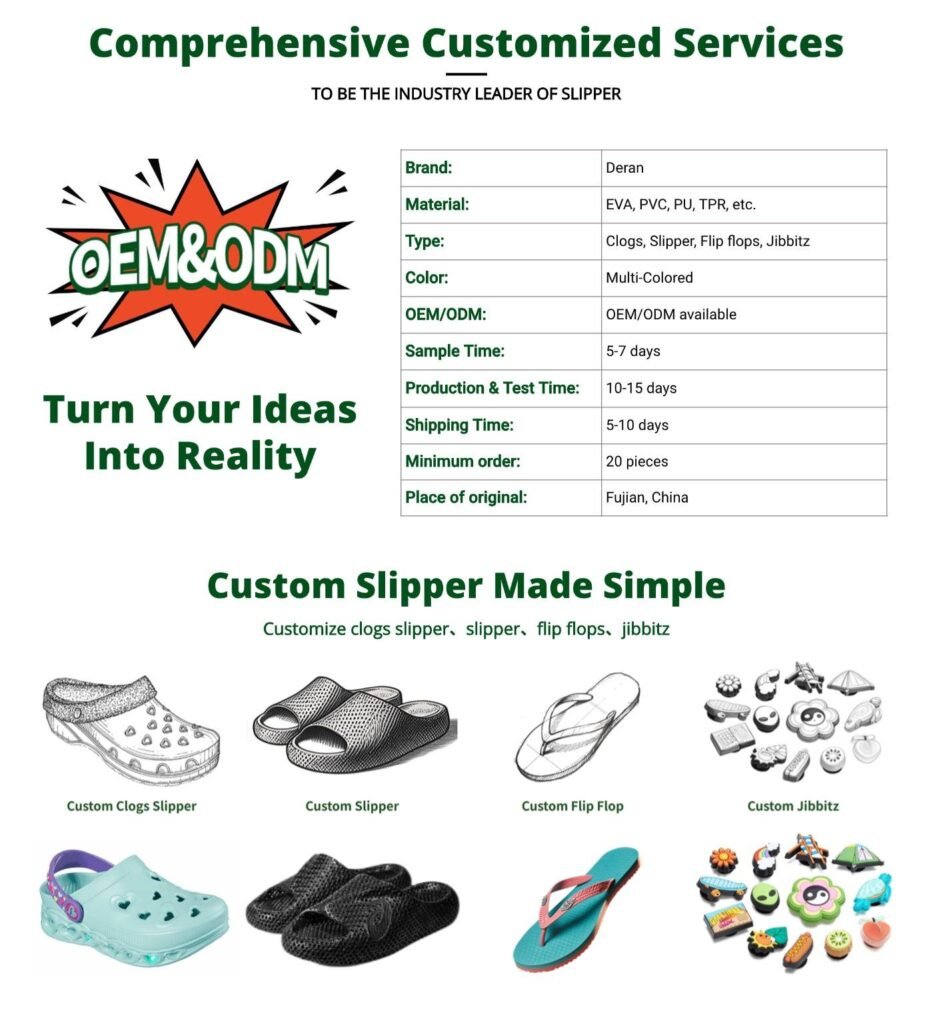

Deran is such a leading OEM & ODM eva slipper manufacturer in China that has been deeply engaged in slipper manufacturing for more than 20 years. From classic EVA slippers and flip-flops to popular Crocs hole shoes and creative shoe accessories, Deran can not only meet the diverse customization needs of brand customers, but also provide customers with full-process support from market research, design proofing, mold development, production management to quality control and logistics assistance.

Table of contents

- Who is Deran: A model of China’s slipper manufacturing strength

- Detailed explanation of the OEM & ODM slipper customization process

- Diversified product lines: One-stop service for slippers, flip-flops, Crocs and shoe accessories

- Why global brands choose Deran for cooperation

- What details should be paid attention to when customizing slippers?

- Customer success story: How to create a hit slipper product through Deran

- Deran’s future layout and sustainable manufacturing vision

Who is Deran: A model of China’s slipper manufacturing strength

Founded in Fujian, China, Deran has a complete supply chain, a mature manufacturing ecosystem and rich technical talent resources. As an OEM & ODM slipper factory focusing on slippers, casual shoes and home footwear products, Deran has adhered to the concept of “quality as the basis, innovation as the soul, and service as the basis” since its inception, and is committed to providing personalized, high-quality and market-competitive footwear products to global customers.

Deran has its own modern factory with a production area of more than 10,000 square meters, an annual output of more than 5 million pairs of slippers, and is equipped with more than 10 injection molding and molding production lines, covering EVA, PVC, TPR, rubber and other material processing processes. The company is equipped with a mold workshop, a proofing center, a quality laboratory and a packaging workshop, which can complete every step from sample design to order delivery. In addition to mass production capabilities, Deran also focuses on R&D innovation, with more than 10 experienced designers and material engineers, who can develop new products according to market trends and quickly respond to customer customization needs.

Over the years, Deran has successfully provided OEM and ODM services to more than 50 brand customers in Europe, America, the Middle East, Japan and South Korea, covering large supermarket retailers, clothing brands, footwear brands, e-commerce platform brands, etc., and has become one of the manufacturing companies with high export customer satisfaction in China’s slipper industry.

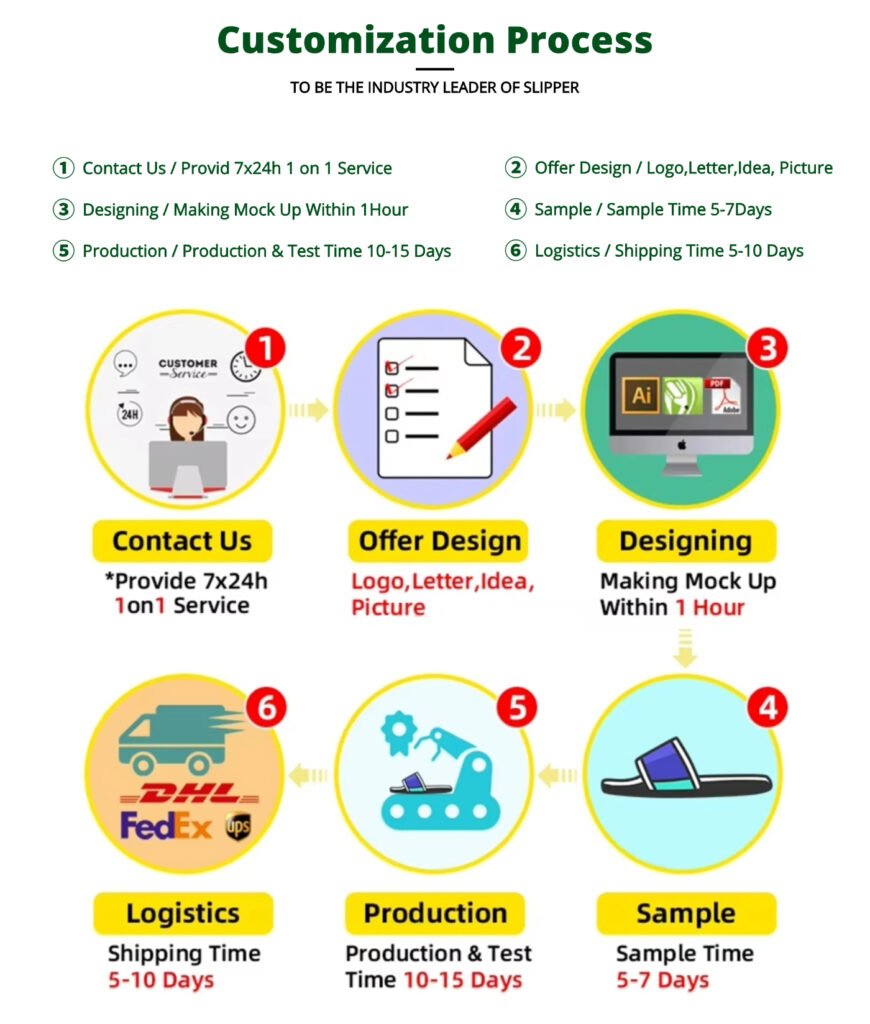

Detailed explanation of the OEM & ODM slipper customization process

A successful slipper product, from concept to market, is not a one-time process. Deran has formed a set of efficient, transparent, professional and reliable customization processes over the years to ensure that every customer’s creativity can be accurately implemented.

Project consultation and demand communication

The customer provides a preliminary product concept or reference diagram, and the Deran sales and design team assists the customer in clarifying the product direction, including usage scenarios, target markets, budget ranges, etc., to lay the foundation for subsequent customization.

Material recommendation and design plan

Depending on the product type and usage requirements, Deran will recommend suitable materials (such as EVA lightweight foam, PVC anti-slip material, rubber outsole, etc.) and structural processes. The design team draws renderings, 3D models, and even visual videos according to customer needs.

Proofing and mold development

After the customer confirms the plan, Deran’s internal sample center can complete the initial sample within 3-5 days, and conduct trial testing and appearance optimization. After confirming the sample, if mold opening is required, the exclusive production mold will be made by its own mold workshop to ensure mass production accuracy.

Production scheduling and quality control

After the mold is completed, it enters the mass production stage. Deran’s intelligent injection molding machine and pressing assembly line can efficiently complete mass production. The QC department follows up the whole process. From raw materials, semi-finished products to finished products, there are strict sampling and functional testing mechanisms to ensure product stability and consistency.

Packaging and delivery logistics

Color boxes, OPP bags, environmentally friendly packaging and other forms can be customized according to customer requirements, and labeling, packing, code sheet printing and other services are supported. Deran has many years of foreign trade experience and can assist in arranging one-stop logistics distribution by sea, air and express.

The whole process is extremely customer-friendly. Whether it is a mature brand or a new brand that is just starting out, you can get professional and transparent full-process service support.

Diversified product lines: One-stop service for slippers, flip-flops, Crocs and shoe accessories

Deran is not just a manufacturer of a single product, but a comprehensive footwear manufacturing company covering multiple categories, multiple markets, and multiple subdivided functions. Its product lines include:

EVA slippers: light and elastic, suitable for home, beach, travel and other scenes, it is the entry-level hot-selling choice for most customers. Deran can provide a variety of molds and texture combinations.

Flip-flops: classic tropical products that are water-resistant and non-slip, suitable for Southeast Asia, the Middle East, and Africa. Rich material selection and flexible price range.

Crocs-style hole shoes and shoe accessories: The hole shoe market has exploded in Europe and the United States in recent years. Deran can produce various types of hole shoe bodies and support Jibbitz-style customized shoe accessories to create a sense of fashion and personal expression.

Home slippers and warm shoes: suitable for winter and e-commerce platform sales, using coral fleece, super soft fabrics, PU edging and other structures.

Children’s shoes and parent-child models: support the simultaneous development of adult and children’s styles to meet the needs of family consumption brands and increase the stickiness of product lines.

This rich product line not only helps customers with one-stop shopping, but also allows them to quickly switch product focus in different seasons and markets.

Why global brands choose Deran for cooperation

The reason why Deran stands out is due to its continuous accumulation and optimization in multiple key dimensions:

Rich experience: more than 20 years of export OEM experience, familiar with footwear standards and factory inspection processes in Europe, America, Japan, the Middle East and other regions, to avoid customers taking detours.

Professional team: a manufacturing team of more than 200 people, 10 design and development personnel, and an exclusive foreign trade follow-up team to ensure that there is a dedicated person in charge of each link.

Technical capabilities: multiple EVA injection molding lines and a full set of TPR/PVC processes, supporting special processes such as two-color molding, anti-slip textures, laser engraving, and sole ventilation holes.

Cost control: With a self-built mold center and supply chain system, it reduces customers’ overall procurement costs while ensuring quality.

Service support: not only provide manufacturing, but also participate in customer product selection, market analysis, packaging suggestions, logistics recommendations and other links. It is a strategic partner rather than a single supplier.

Long-term cooperation with more than 50 customers worldwide, including well-known European and American supermarket chains, independent brands, and e-commerce platform merchants. The annual repurchase rate of most customers exceeds 80%.

What details should be paid attention to when customizing slippers?

Many brands tend to overlook some key details when customizing slippers for the first time, and these details often directly affect the quality of the final product and market acceptance. Deran summarizes the following practical suggestions based on years of experience:

Material selection should match the purpose:

- Home slippers recommend EVA + soft suede

- Beach slippers are suitable for waterproof PVC or TPR outsole

- Business simple models can use PU leather + composite insole

The pattern of the sole mold determines the anti-slip effect: The pattern depth and structure of the mold determine the friction of the shoe on the ground, especially the outdoor style, which needs to focus on evaluating and testing the anti-slip level.

Color matching needs to consider batch stability: Although bright colors attract attention, the source of dyes and batch stability should be considered to avoid serious color differences between different batches.

Packaging structure affects freight costs: Customized color boxes enhance product image, but also increase volume and weight. It is recommended to choose a reasonable packaging form according to the sales scenario.

International certification needs to be prepared in advance: If you need to enter the European and American markets, you should consider material safety certification requirements such as REACH, CPSIA, and CA65. Deran can assist in providing corresponding test reports.

Customer success story: How to create a hit slipper product through Deran

Take a British lifestyle brand as an example. Before choosing Deran, the brand tried several small manufacturers and could not solve the problems of product stability and delivery time. After cooperating with Deran, Deran redesigned the EVA slipper mold for it and recommended matching it with a shoe last structure suitable for European feet. At the same time, it optimized the packaging and enhanced the brand sense.

In the first month of launch, the series sold more than 15,000 pairs on the British e-commerce platform, ranking among the top 3 in the category. In the second quarter, the company added a customized series of flip-flops and Crocs, and expanded to the French and German markets in the third quarter. Deran became its strategic cooperation factory, and new products will be jointly developed every quarter.

Deran’s future layout and sustainable manufacturing vision

Under the global environmental protection trend, Deran is also actively engaged in the practice of sustainable manufacturing:

- Introducing bio-based EVA materials to reduce petrochemical dependence

- Developing recyclable TPR slipper structures to extend the life cycle of shoes

- The factory uses a solar power generation system to reduce carbon emissions

- The packaging turns to environmentally friendly pulp boxes and water-based ink printing

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Whether you are a start-up brand, a mature shoe merchant, a cross-border e-commerce platform, or an international chain retail group, Deran China Slipper Manufacturer can provide you with professional, efficient and trustworthy OEM & ODM slipper customization services. Its more than ten years of manufacturing accumulation, complete production line structure, diverse product layout, and service capabilities throughout the entire process of design, proofing, mass production, and delivery allow brand owners to focus more on the market and marketing.

Choosing Deran is to give your brand wings. Contact us now and move towards a higher market stage together!