Table of contents

- What are Crocs?

- Demand and development trend of Crocs in the European market

- Deran’s brand advantage as the top Crocs manufacturer in Europe

- Detailed explanation of the Crocs shoe accessories customization process: from design to delivery

- Deran’s manufacturing capabilities revealed: analysis of the entire process of materials, molds, and quality control

- Cooperation advantages: Detailed explanation of OEM/ODM customized services provided by Deran

What are Crocs?

Crocs, a shoe brand that was originally considered “not fashionable enough”, has successfully counterattacked in recent years and has become a trend icon sought after by young people around the world. Crocs shoes originated in 2002 and were invented by three American entrepreneurs. At first, they were anti-slip shoes designed for sailing. The design was inspired by the practical needs of comfort, lightness and waterproofness. The shoe body is made of a unique foaming resin material with good softness and shock absorption.

The reason why this shoe is called “Crocs” is that the shape of the shoe body is similar to the sole of a crocodile, and it has strong adaptability and durability, just like a crocodile can move freely in various environments. To date, Crocs is no longer just a functional shoe. It has been integrated into the trend culture, DIY decorated by young people, worn with socks, and even walked on the T stage of Fashion Week.

The biggest features of Crocs shoes are: comfortable, anti-slip, breathable, waterproof, suitable for many occasions such as beaches, kitchens, hospitals, homes, and outdoors. This fully molded EVA structure shoe body has no laces or stitches, making it easy to put on and take off, and is a typical representative of “lazy shoes”. Especially during the global epidemic, Crocs has become a favorite of medical staff and people at home because of its advantages such as easy cleaning, lightness and waterproofness.

Today, Crocs has developed multiple series such as classic hole shoes, sandals, casual shoes, thick-soled shoes, sports shoes, etc., and it is also more interesting and self-expressive because it can be personalized with shoe decorations (Jibbitz).

Demand and development trend of Crocs in the European market

In Europe, the popularity of Crocs has increased year by year, especially in Germany, France, Italy, the Netherlands, Northern Europe and other countries. Many European consumers’ comments on Crocs are concentrated on: “I don’t want to change shoes after wearing them once” and “It’s as comfortable as stepping on cotton.” With the change of lifestyle, more and more people choose comfortable, practical and easy-to-care shoes, which makes Crocs enter a wider range of home and work scenes.

According to Statista, sales of Crocs-related categories in Europe have grown by more than double digits in the past five years, especially in the children and middle-aged and young market. Young European consumers prefer products that can show their personal style, and Crocs fits this trend. The Jibbitz shoe decoration system also allows consumers to decorate the uppers by themselves, which improves interactivity and user stickiness.

In addition, the concept of environmental protection continues to rise in the hearts of European consumers. The Crocs brand promises to achieve carbon neutrality by 2030, and manufacturers with environmentally friendly production lines like Deran have also won the favor of more European brands and retailers because of this trend.

Deran’s brand advantage as the top Crocs manufacturer in Europe

As a company that has been deeply involved in the design and manufacturing of Crocs products for many years, Deran has grown into one of the crocs wholesale suppliers with high recognition in the European market. Deran not only has complete R&D capabilities, but also can provide customers with a full chain of services from mold development to whole shoe production to personalized shoe accessories.

Deran’s team is composed of a group of senior professionals familiar with footwear design, material engineering, mold processing and international trade. They know every detail of Crocs products, including the shoe structure, hole distribution, sole rebound, and accessory firmness. Every pair of products shipped must pass dozens of manual and mechanical tests to ensure that every pair of Crocs that consumers get is comfortable, safe, and durable.

At the same time, Deran also has a number of modern injection molding production lines, which can achieve efficient and highly consistent mass customization production. More importantly, Deran also has a unique design style in product color matching, surface treatment, and shoe accessories development, which can meet the dual needs of European customers for personalization and aesthetics.

Detailed explanation of the Crocs shoe accessories customization process: from design to delivery

Many customers choose Deran because of its mature process and experience in Crocs shoe accessories customization. Crocs shoe accessories, also known as Jibbitz accessories, are one of the key factors driving the popularity of Crocs in recent years. Consumers can install cartoon images, brand logos, totem texts, etc. on the upper holes of the shoe surface in the form of fasteners.

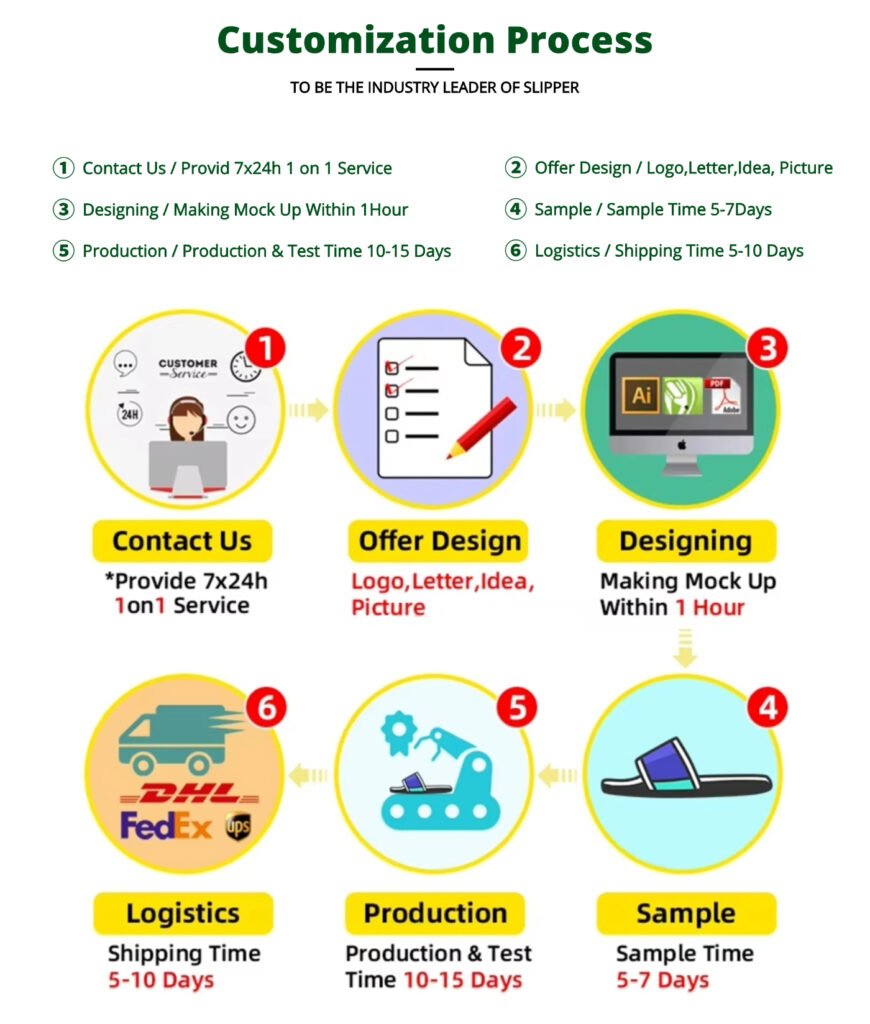

The usual process for customized cooperation in Deran is as follows:

Demand communication: customers provide the desired pattern, material or functional concept; Deran provides consulting advice.

Design proofing: Deran professional designers draw renderings and make samples according to the requirements.

Customer confirmation: customers review the actual samples and make modification suggestions.

Mold development: After confirming the plan, Deran factory starts mold processing to ensure the consistency of bulk goods.

Mass production: All production processes are completed within a controllable time, from injection molding, spraying to assembly, all carried out in its own factory.

Quality inspection and packaging: Each batch of products must pass functional testing, color calibration, and strength testing.

Shipping and delivery: Arrange sea transportation, air transportation or dedicated logistics according to the customer’s region to ensure on-time delivery.

Deran can provide one-stop service for this entire process, greatly saving customer communication and coordination costs, making cross-border cooperation more efficient and worry-free.

Deran’s manufacturing capabilities revealed: analysis of the entire process of materials, molds, and quality control

Although we don’t talk about complex data, Deran’s manufacturing strength is obvious to all. First of all, in terms of material selection, Deran uses EVA foam materials and TPR environmentally friendly materials with the same quality standards as major international brands. These materials are not only soft, non-slip, and non-toxic, but also have good wear resistance and a long wearing life.

In terms of molds, Deran’s factory has built its own mold workshop, equipped with CNC machine tools and 3D modeling systems, which can quickly develop exclusive shoe shapes and shoe decoration molds for customers. For example, if a customer proposes to imitate the “astronaut” theme of hole shoes, Deran designers can complete 3D modeling within 3 days and output printed samples for evaluation.

In terms of quality control, Deran implements a “multi-point quality inspection” system. That is, from the storage of raw materials, production injection molding, shoe body finishing, shoe decoration assembly, and finished product packaging, each process has an independent inspection point. Employees need to conduct appearance inspection, firmness test, wearing comfort test, etc. according to the process manual to ensure that each pair of shoes can pass multiple inspection standards before leaving the factory.

In addition, Deran also provides special processing services for some customers, such as antibacterial treatment, UV printing, laser engraving logo, etc., to enhance the added value of products and meet the changing needs of the European retail market.

Cooperation advantages: Detailed explanation of OEM/ODM customized services provided by Deran

As a professional Crocs shoes manufacturer, Deran is not only good at “production according to drawings”, but also good at original development “from scratch”. Whether the customer is a brand with a design plan but lacks the ability to implement it, or a distributor with market ideas but no design drawings, Deran can cooperate with customized development from 0 to 1.

The OEM/ODM services provided by Deran include:

- Shoe design and development (adult/children/couple shoe)

- Jibbitz shoe accessories design and matching

- Logo implantation and personalized color matching

- Packaging design and environmentally friendly material replacement

- Multilingual labels, customs declaration information assistance

More importantly, Deran is well versed in European regulations and consumer product safety certification processes, and can avoid possible violations in the product design stage. For example, it has rich experience in REACH environmental standards and the use of CE marks. Many customers have reported that working with Deran can not only ensure quality, but also reduce problems caused by certification, customs clearance and other links in the later stage.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Crocs’ popularity is not accidental, but a perfect combination of comfort, fashion and function. In this niche track, Deran has become a trusted partner of many brands in Europe and even the world with its professional manufacturing capabilities, flexible customization services, good delivery time and quality control.

Choosing Deran is not just choosing a foundry, but also choosing a long-term strategic partner who understands products, markets and brands. From material research and development to product delivery, from shoe body design to shoe accessories innovation, Deran always adheres to customer needs as the core and wins trust with practical actions.

In the future, as the Crocs culture continues to heat up, consumers’ demands for personalization, diversification, and environmental protection will continue to increase. Deran will continue to assist more brands in developing more competitive Crocs products with an open and innovative attitude, leading a new trend of footwear that emphasizes both comfort and fashion.