Table of contents

- Deran’s Professional Background: From Crocs Manufacturer to Customisation Expertise

- The first step of customised Crocs shoes: design requirements and functional analysis

- Materials and Manufacturing Process: Key to Creating High-Quality Custom Crocs Shoes

- From prototyping to mass production: every critical step in Deran’s factory

- Why more and more brands choose Deran for Crocs customisation?

Deran’s Professional Background: From Crocs Manufacturer to Customisation Expertise

Established in 2005, Deran is a professional manufacturer focusing on slippers, Crocs-type injection moulded shoes, flip-flops, fur slippers, Jibbitz shoe rips, etc. Deran is committed to providing global customers with OEM, ODM and wholesale services, and has accumulated more than 20 years of experience in shoe manufacturing.

The company has the following core manufacturing strengths:

- Factory area over 15,000 square metres

- 4 automatic production lines

- Daily production capacity of over 20,000 pairs, with a monthly production capacity of 400,000 pairs

- Minimum order quantity is only 20 pairs

- Proofing in as little as 3 days

As a crocs manufacturer, Deran not only excels in production capacity and quality control, but is also favoured by global customers for its efficient response, quick return of small orders and full-process customer collaboration, especially for cross-border e-commerce brands, DTC independent sellers and wholesale distributors, etc. We insist on the principle of ‘customer first’.

We adhere to the principle of ‘customer first’, and have a 24/7 consultant response team and project managers to ensure that every customer can get an efficient and smooth experience from idea to implementation.

The first step of customised Crocs shoes: design requirements and functional analysis

Before customising Crocs shoes, the most important step is to clearly define the product’s usage scenarios, target group and brand visual direction, Deran provides all-round design assistance from creative sketches to structural suggestions.

1. Multi-dimensional functional positioning analysis

- Medical/workwear: Anti-slip, anti-static and anti-bacterial materials are recommended, with a focus on the sole pattern and support

- Outdoor sports: it is recommended to strengthen the abrasion resistance of the sole, the elasticity of the foot feeling and the waterproof treatment

- Fashion: more emphasis on colour matching, shoe pulling and logo display

Deran has an experienced development team to provide structural optimisation suggestions, colour matching guidelines and mould matching solutions according to different market needs.

2. Design tools and documentation support

Customers can use common software (AI, Rhino, CLO, etc.) to submit the first draft of the design, or we can provide standard templates to assist in generating the appearance of the product, the distribution of sketches of the accessories, colour schemes and other content, greatly improving the efficiency of sampling.

We also support Pantone colour code customisation, and recommend sole hardness, vamp holes and material density according to brand positioning, enabling directional design from structure to experience.

Materials and Manufacturing Process: Key to Creating High-Quality Custom Crocs Shoes

In order to produce a pair of comfortable and durable Crocs shoes with strong market competitiveness, it is indispensable to have a scientific grasp of materials and processes.

Wide selection of materials to meet different market needs

We can provide the following mainstream materials according to the target market and product positioning:

- EVA: light, soft and good cushioning.

- TPR: good elasticity, non-slip and wear-resistant.

- TPU: high strength, wear-resistant, suitable for high-grade footwear.

- Croslite: high quality and softness.

All materials can provide environmental protection test reports, in line with REACH, ROHS, OEKO-TEX, TUV and other international certificates, support exports to Europe, America, Japan, Southeast Asia, the Middle East and other places.

Mature injection moulding technology and experienced mould development

Deran has a mould development and independent sampling workshop, with high precision control and long service life of the moulds. Together with the automatic injection moulding line, the sole and upper can be moulded in one piece, with strong process stability.

Each pair of shoes passes a strict quality inspection process, including mould fit, injection pressure, cooling time and appearance quality, to ensure batch consistency and comfort.

From prototyping to mass production: every critical step in Deran’s factory

Deran provides complete OEM&ODM customisation services, covering the entire process from product design confirmation, tooling development, prototyping, performance testing, to mass production, packaging and logistics.

- Design Confirmation Stage:After the customer submits the design proposal, Deran’s design team will evaluate the design file and provide technical feedback in conjunction with the material and production process to ensure the manufacturability and functionality of the design.

- Mould Development:A team of experienced mould engineers develops injection moulds based on the design. Deran pays attention to the precision and durability of the moulds to ensure the stability of subsequent mass production.

- Sample Proofing:The first sample can be completed in 3 days at the earliest, and the sample can be confirmed by the customer before proceeding to the next step. Support small batch flexible sampling, suitable for emerging brands to quickly verify the effect of the product.

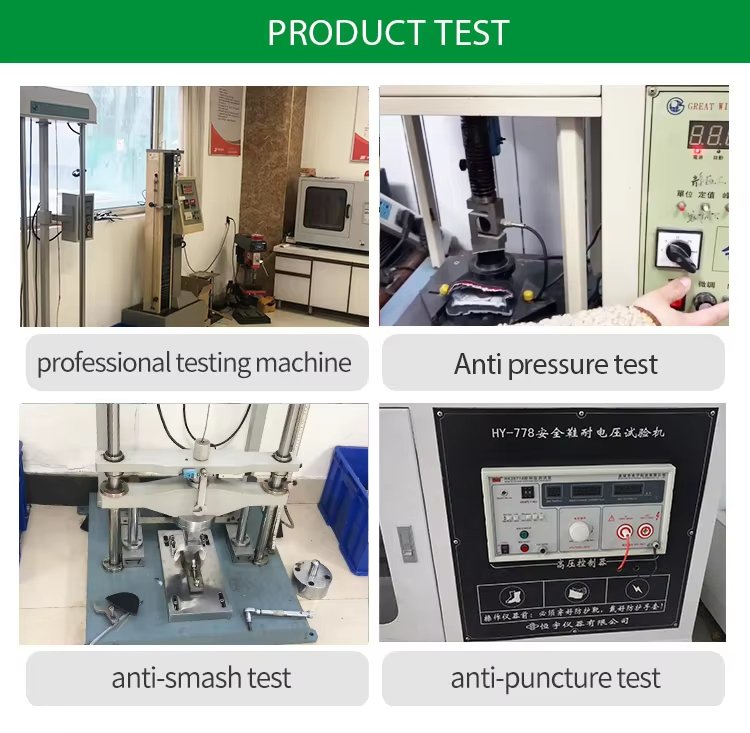

- Performance testing:Samples pass a number of functional tests such as wear resistance, anti-slip, comfort, etc. to ensure that they meet market and customer standards.

- Mass Production:At the mass production stage, the factory has multiple quality inspection processes to strictly control product quality. The production line operates efficiently to ensure that orders are delivered on time.

- Packaging and Shipping:Deran provides customised packaging services, including brand logos and eco-friendly material packaging solutions. Deran also co-ordinates logistics to ensure that the products arrive at the customer’s designated location.

The entire process is overseen by a professional project management team, and the foreign trade team responds to customer needs 24/7, ensuring timely and efficient communication and transparent and controllable project progress.

Why more and more brands choose Deran for Crocs customisation?

Many brands choose Deran as their Crocs customisation partner, mainly based on the following advantages:

- Rich industry experience:More than 20 years of footwear manufacturing history, focusing on Crocs and slippers products, has accumulated deep technical and production management experience.

- Flexible Customization Service:Support multiple SKUs, multiple colours, mixed orders, small batch starting quantity as low as 20 pairs, to meet the needs of brands of different sizes.

- Strict Quality Control:Quality inspection nodes are set up for each process, with a product qualification rate of more than 99%, and we have passed international customers’ factory inspection and quality audits for many times.

- Environmental Protection and Compliance Certification:Our products have passed REACH, ROHS, OEKO-TEX®, TUV and other international authoritative environmental protection certifications, which comply with the strict regulations of Europe, America, Southeast Asia and the Middle East markets, and help our customers improve their brand image.

- Advanced equipment and professional team:15,000 square metres of modern factory buildings, multiple automated production lines, experienced design, mould and quality inspection team to ensure product quality and efficiency.

- Perfect design support:Independent design department assists customers to complete the brand logo placement, packaging art and colour scheme, truly achieving a seamless connection from creativity to landing.

- Fast Response and Efficient Communication:Professional foreign trade and project management team is online 24/7 to ensure smooth customer communication and timely advancement of production orders.

These advantages make Deran the preferred partner for many brands to personalise Crocs shoes, helping customers to stand out in the fierce market competition and create differentiated high-quality products.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

In today’s competitive footwear market, Deran stands out as a trusted crocs manufacturer and reliable partner for custom Crocs shoes. With over 20 years of experience, advanced manufacturing capabilities, and a commitment to quality, flexibility, and sustainability, Deran empowers global brands to bring their creative ideas to life—whether for small-batch startups or high-volume enterprise orders.

If you’re looking for a partner who understands the art and science of Crocs customization, Deran is here to turn your vision into comfortable, durable, and market-ready products.