Table of contents

Deran’s Unique Advantages as a Custom Slide Manufacturers

Since its establishment in 2005, Deran Slipper Factory has over 20 years of professional experience in slipper manufacturing, making it one of the most recognized custom slide manufacturers worldwide. As a factory specializing in OEM/ODM services, Deran has notable advantages in design, production, and customization processes.

Factory Scale and Production Equipment

Deran has 4 advanced production lines with a monthly capacity of 400,000 pairs, capable of flexibly handling both large and small orders. The factory is equipped with high-precision injection molding machines, automatic pressing machines, cutting equipment, and fully automated assembly lines, ensuring that each pair of custom made slides maintains consistency in size, comfort, and appearance.

Material Selection and Innovation

Deran offers a variety of materials, including EVA, natural rubber, PU, and linen/ bamboo fiber blends. EVA is lightweight and flexible with good cushioning; natural rubber is durable and suitable for outdoor use; PU provides premium texture and durability; linen and bamboo fiber blends are environmentally friendly and sustainable. All materials are rigorously tested to ensure comfort, durability, and compliance with international standards.

Rapid Sampling and Small Batch Customization

Deran supports fast sampling, typically taking 5-7 days, allowing clients to quickly validate design effects. Small batch production can be completed in 12-24 hours per batch, enabling startups, limited editions, or seasonal products to reach the market rapidly while reducing inventory pressure.

Certifications and International Cooperation Experience

Deran holds REACH, ROHS, and OEKO-TEX certifications, ensuring material safety and environmental compliance. Long-term cooperation with overseas brands has provided rich OEM/ODM experience, enabling compliance with various market regulations and quality standards, delivering reliable custom made slides solutions to global clients.

Detailed Steps of Custom Slides Production

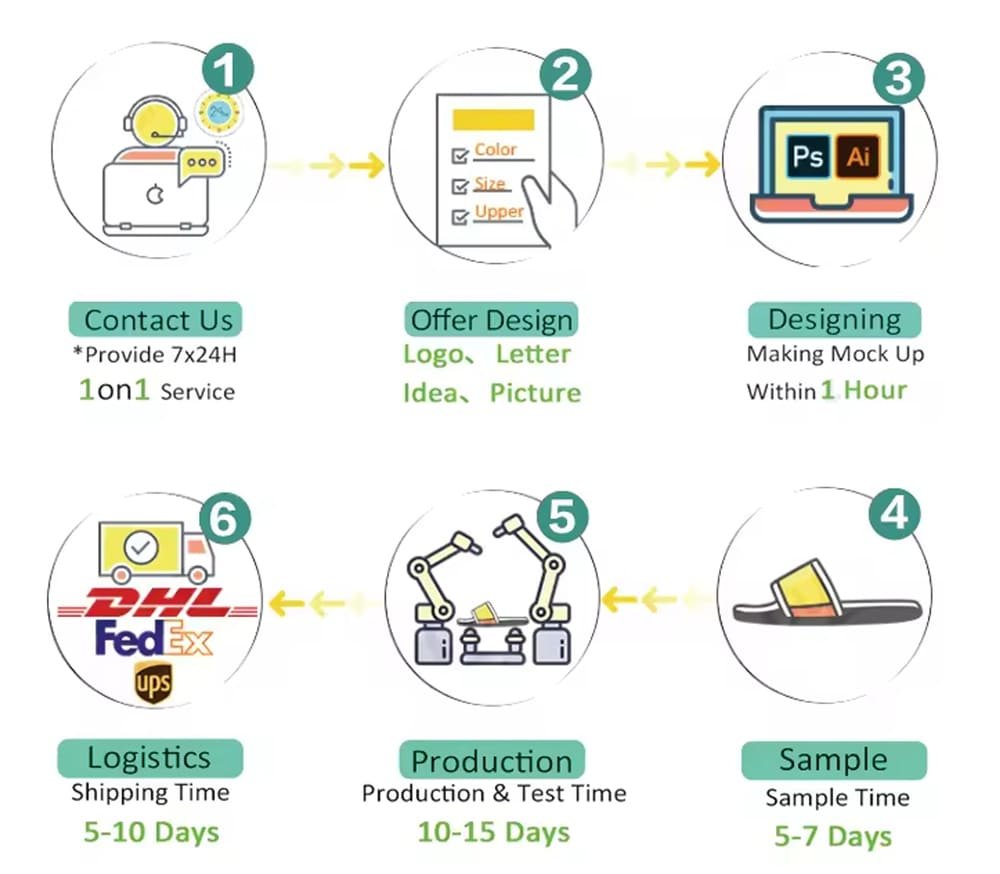

High-quality custom made slides require a standardized production process. Deran strictly follows the full process from design to delivery to ensure that every pair meets client requirements.

- Design and Communication: Each project starts with comprehensive communication. Clients can provide design concepts, brand logos, color preferences, shoe type requirements, and special functions such as adjustable straps or textured uppers. Deran’s design team uses advanced CAD software to model designs, allowing clients to preview realistic renderings and make adjustments before sample production to ensure the final product meets expectations.

- Mold Development and Sample Production: Once the design is confirmed, Deran develops molds using high-precision CNC equipment. Sample production usually takes 5-7 days and includes comfort, sizing, material, and appearance testing. Rapid sample iteration ensures that batch production starts with the best design, reducing modification costs later.

- Mass Production Process: After sample approval, mass production begins. The process includes injection molding, pressing, upper and sole assembly, surface treatment, and logo customization. Automation ensures efficiency, while quality control at every step guarantees consistency with approved samples.

- Quality Inspection and Packaging: Each pair undergoes strict quality testing, including material density, elasticity, abrasion resistance, and slip-resistance tests. Packaging balances protection and presentation, ensuring safe transport while showcasing brand identity. This high-standard management ensures that clients receive products that meet their expectations.

Key Factors in Custom Slides Design and Comfort

Comfort is the core of custom made slides design. Deran has extensive experience in ergonomic design, material selection, and aesthetic customization.

- Ergonomic Design: Deran uses 3D foot scanning and pressure distribution analysis to optimize sole curves and arch support points, ensuring comfort during extended wear. Sole thickness and bending points are scientifically calculated to promote natural walking and reduce foot fatigue.

- Slip-Resistance, Water-Resistance, and Durability: Slides are often used for leisure and outdoor activities, making slip-resistance and durability essential. Deran’s textured soles enhance friction, wear-resistant materials extend shoe life, and water-resistant treatments allow wear in damp conditions. Each design balances functionality and comfort.

- Color and Logo Customization: Deran offers Pantone color matching to ensure precise brand color representation. Logos can be applied via embossing, silk printing, or heat transfer, creating durable and attractive branding. Clients can incorporate brand concepts or creative elements into their custom made slides for personalized expression.

- Sustainable Design: Environmental sustainability is a key trend in modern footwear. Deran provides EVA, natural rubber, and bamboo fiber blends to reduce environmental impact. Production processes are optimized to minimize energy consumption and waste, helping brands offer high-quality custom made slides while supporting green initiatives.

Quality Assurance and Safety Standards

High-quality custom made slides are not only about comfort and appearance but also require strict quality control and safety standards.

- Quality Control Process: Deran implements full-process quality management. Each batch undergoes material inspection, wear testing, elasticity tests, and slip-resistance checks. Statistical sampling ensures stability and consistency in mass production.

- International Certifications and Regulatory Compliance: With REACH, ROHS, and OEKO-TEX certifications, Deran’s custom made slides meet international environmental and safety standards. These certifications protect users’ health and facilitate smooth market entry in Europe, the Americas, and other regions.

- Durability and Safety: Through long-term wear simulations and environmental adaptation tests, Deran ensures every pair of custom made slides is comfortable, safe, and durable, reducing complaints and returns while enhancing brand credibility.

Frequently Asked Questions (FAQ) about Custom Slides

Q: What is the minimum order quantity for custom slides?

A: The minimum order quantity for custom slides is 50 pairs, suitable for startups, small batch production, or limited edition products.

Q: How long does it take to produce a sample?

A: Sample production generally takes 5-7 days, allowing clients to quickly validate designs.

Q: How long does mass production take?

A: Mass production usually takes 10-15 days, depending on order quantity and design complexity.

Q: Can I add my logo or personal design to the slides?

A: Yes. Deran provides OEM/ODM services so clients can incorporate logos, letters, creative patterns, or personal design elements into samples and mass production.

Q: What materials are used to make the slides?

A: Common eco-friendly materials include EVA, natural rubber, linen, and bamboo fiber blends, ensuring comfort, durability, and sustainability.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Choosing a professional custom slide manufacturers like Deran is a smart choice for brands and individuals seeking high-quality custom made slides. With 20 years of industry experience, advanced production facilities, diverse material options, and fast response capabilities, Deran transforms client creativity into premium customized slides.

Whether it is wooden slippers, flip-flops, Gibts slides, or fur slippers, Deran provides ergonomically designed, durable, attractive, and eco-friendly products. Through OEM/ODM services, clients can achieve personalized branding while ensuring compliance with international standards.

Collaborating with Deran guarantees professional, reliable, and efficient custom services, making every pair of custom made slides a perfect blend of brand identity and comfortable experience. Begin your customization journey with Deran to maximize your brand and creative value.