Table of contents

Deran’s Professional Experience and Manufacturing Strength

- Extensive Industry Experience: Since 2005, Deran has specialized in slides manufacturing, accumulating over 20 years of expertise. The company has strong capabilities in design, material selection, production processes, and quality management, providing global clients with high-quality custom made slides.

- Advanced Production Facilities: Located in China’s core footwear hub, Deran’s factory covers 4,000 square meters and has four modern production lines, including injection molding, stamping, and assembly. The monthly capacity reaches 400,000 slides, meeting large-scale order demands.

- Professional Team and Technical Capability: With over 100 skilled technicians and designers, the team is well-versed in international markets including Europe, North America, Japan, Korea, and Southeast Asia. They offer 3D modeling and rapid sample services to ensure efficient delivery from design to finished product.

- Global Collaboration Experience: Deran has provided OEM/ODM services for over 300 overseas clients, including Amazon brands, retail chains, and brand agents, building strong credibility and authority in the global market.

- Customer Service and Professional Commitment: Providing 24/7 online support, Deran responds quickly to customer needs. Following the principle of “customer first, continuous improvement,” the company customizes professional solutions for every client.

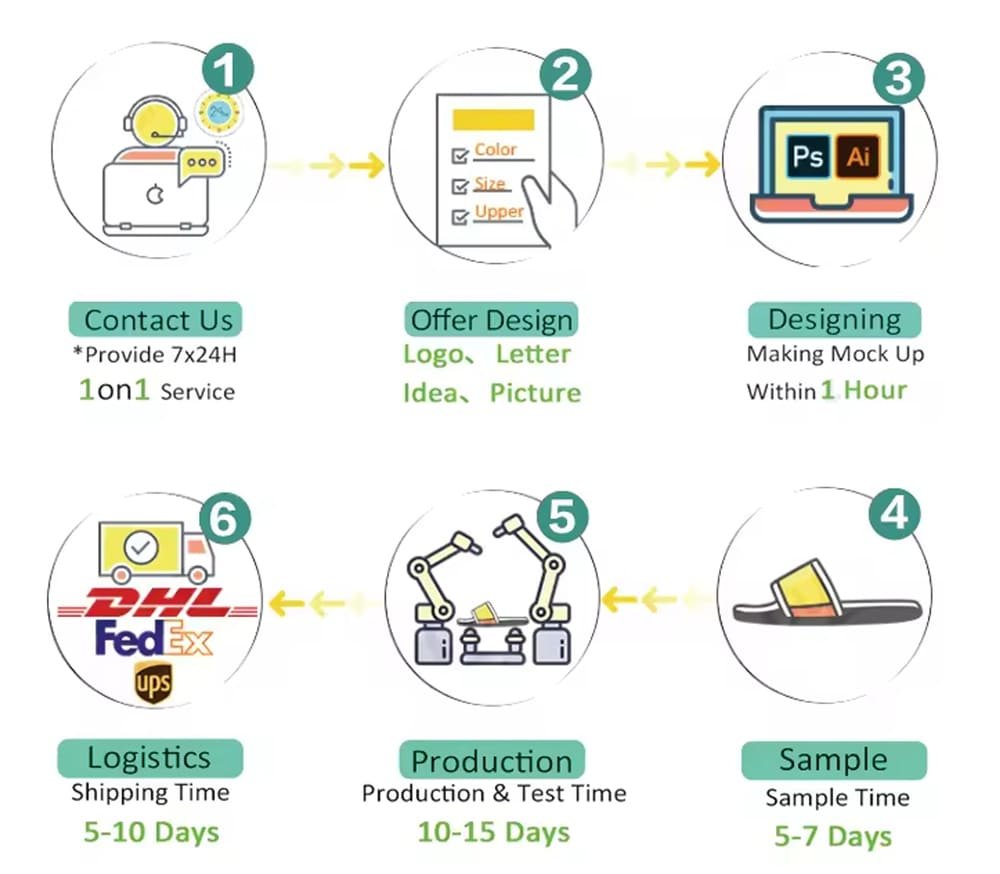

Deran’s Custom Design Process

- Client Communication and Needs Analysis: Offering 24/7 one-on-one service, Deran understands brand positioning, product requirements, and design concepts to deliver tailored custom made slides.

- Design and Rapid Prototyping: Using 3D modeling software, the rapid prototyping department can produce samples within 5–7 days, allowing clients to quickly test market responses.

- Material Selection and Personalized Customization: Deran provides environmentally friendly materials, including EVA, TPR, PU, and natural rubber. Softness, wear resistance, and comfort can be adjusted to meet diverse client needs.

- Logo and Pattern Printing: Supports screen printing, heat transfer, transfer printing, and embroidery to ensure clear and durable logos. Packaging can be customized to enhance professional brand image.

- Production and Quality Confirmation: Once the sample is approved, mass production begins, generally taking 10–15 days. Production undergoes strict quality inspections to ensure products meet design and material standards.

Deran’s Manufacturing Process and Technical Advantages

- Core Production Process: Using injection molding, stamping, and assembly processes, Deran ensures elasticity, wear resistance, and firm bonding of the slide sole and upper, providing a high-quality foundation for every custom made slide.

- Surface Treatment and Anti-Slip Design: The sole is designed with anti-slip patterns to enhance safety, durability, and comfort across different surfaces.

- Strict Quality Control: From raw material inspection to production monitoring, each batch undergoes tests for size, strength, wear resistance, and environmental standards, ensuring compliance with design and material requirements.

- Rapid Production Advantage: Single-batch slides can be initially produced within 12–24 hours, with expedited production options to meet urgent market demands.

- Automation and Precision Equipment: The factory is equipped with fully automated injection machines, laser cutting devices, and multiple assembly lines, improving production accuracy and efficiency while reducing human error.

- Custom Process Support: Sole hardness, upper softness, and overall structure can be adjusted according to client requirements, achieving personalized brand customization while maintaining comfort and durability.

- R&D and Innovation Capability: With an independent R&D department, Deran can quickly test new materials, processes, and designs. Sample production from design confirmation can be completed in just 5–7 days, increasing product development efficiency.

Safety Standards and Quality Certification

Safety, environmental protection, and quality are key standards when choosing custom slide manufacturers. Deran ensures that every custom made slide is comfortable, durable, and reliable through strict systems and international certifications.

- Environmental and Safety Certification: Products are certified by TUV, REACH, and ROHS, with some materials holding the OEKO-TEX® Standard 100 label. Certification covers the entire process from raw materials to production, meeting international safety and environmental standards.

- Raw Material Safety Control: Only certified environmentally friendly materials, including EVA, TPR, PU, and natural rubber, are used. Every batch undergoes chemical testing to ensure safety and skin-friendly properties.

- Green Production and Sustainability: The factory implements exhaust treatment and water recycling systems. High-efficiency equipment reduces energy consumption and promotes industry-wide environmental standards and ecological upgrades throughout the supply chain.

- Comprehensive Quality Management: Temperature, pressure, and mold precision are strictly monitored on the production line. Each batch undergoes wear, strength, and dimensional testing to ensure compliance with design and durability standards.

- Traceability and Customer Trust: Complete records are kept for each batch, including material lots, production dates, and inspection reports, ensuring traceability and enhancing client and consumer trust.

Deran combines safety, environmental protection, and high quality to provide reliable custom made slides, helping brands establish a strong reputation in global markets.

Frequently Asked Questions (FAQ)

Q: What services do you provide?

A: Deran offers OEM, ODM, customization, and wholesale services, covering the entire process from design to mass production.

Q: What materials are used for slides?

A: Environmentally friendly EVA, TPR, PU, and natural rubber are used, all compliant with TUV, REACH, ROHS, and OEKO-TEX Standard 100 standards.

Q: Can I add my brand logo and design?

A: Yes, Deran supports screen printing, heat transfer, transfer printing, and embroidery. Logos are clear and durable. Packaging can also be customized.

Q: What is the minimum order quantity?

A: The minimum order for custom slides is 50 pairs, supporting small-batch customization to lower market entry barriers.

Q: How long is the sample and prototyping period?

A: Samples take 5–7 days, and single-batch production can be completed within 12–24 hours for rapid market testing.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

With over 20 years of professional experience, complete OEM/ODM customization systems, advanced manufacturing processes, and strict environmental certifications, Deran is a trusted global custom slide manufacturer.

From design and material selection to production and inspection, every step pursues excellence, ensuring clients receive high-quality, personalized custom made slides.

Choosing Deran means choosing reliable quality, sustainable practices, and professional customization services, helping brands stand out in the global market.