Table of contents

Deran’s Technical Advantages in Jibbitz Injection Molding

Since its establishment in 2005, Deran has been focusing on the production and customization of Crocs shoe charms, shoe buckles, and footwear accessories, becoming a leading jibbitz manufacturer in the industry. Deran has extensive experience and technical expertise in material selection, mold design, and injection molding process control, ensuring the high quality and durability of every product.

- Material Application Advantages: Deran is proficient in PVC, TPU, silicone, PP, and other injection molding materials, selecting the most suitable ones for different design requirements. PVC is ideal for colorful and detailed shapes; TPU offers high elasticity and wear resistance; silicone is soft and comfortable, suitable for high-end customization.

- Injection Molding Process Optimization: Deran focuses on controlling temperature, pressure, injection speed, and cooling time, using accumulated standardized processes and experience to effectively prevent common issues such as bubbles, short shots, and warping.

- Complex Shape Handling: Whether it’s two-color molding, gradient effects, or 3D cartoon shapes, Deran achieves high consistency through precise molds and mature processes.

Deran’s technical advantages ensure that customized Jibbitz charms meet high standards in appearance, feel, and durability.

Mold Design and Manufacturing

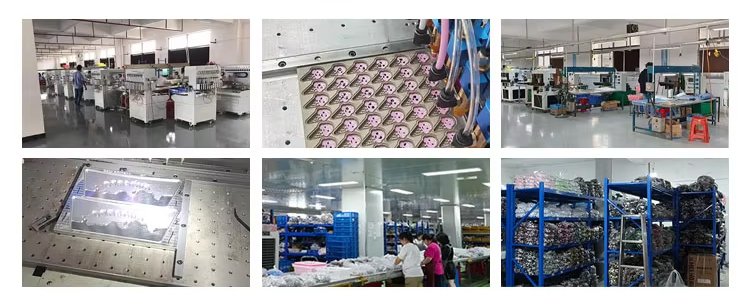

Mold design is the core of the Jibbitz injection molding process, directly affecting product precision, production efficiency, and the delicacy of the finished product. Deran has an independent mold workshop and experienced design team, handling everything from sketch modeling to finished mold manufacturing in-house to maintain strict control at every step.

- Variety of Mold Types: Deran designs single-cavity, multi-cavity, and adjustable molds according to product requirements. Single-cavity molds are suitable for creative customization and small batch production, while multi-cavity molds increase efficiency for large-scale manufacturing. Adjustable molds accommodate different sizes, thicknesses, or 3D shapes, meeting diverse client needs.

- Material Selection and Durability: Deran uses wear-resistant steel or aluminum for molds, balancing mold longevity and machining precision. Steel ensures long-term precision for high-volume production; aluminum is lightweight and fast to process, ideal for rapid prototyping and short-term production.

- Design Key Points and Precision Control: Mold dimensions, draft angles, cooling system design, and vent placement directly affect Jibbitz quality. Deran optimizes cooling channels to ensure uniform material solidification, preventing warping or shrinkage, and designs precise draft angles to reduce stress, improving appearance and durability.

- Rapid Iteration and Sample Verification: Upon receiving client designs, Deran quickly completes mold prototyping using 3D printing or fast milling, providing visual and tactile samples to ensure final production matches expectations.

Jibbitz Injection Molding Technology

The injection molding process determines the forming quality, durability, and detail of Jibbitz charms. Deran’s workflow covers raw material preparation, molten injection, cooling, and post-processing, forming a mature and controllable production system.

- Refined Injection Process: Deran accurately proportionates raw materials and melts them before injection into molds, ensuring uniform mixing. Optimized cooling channels and temperature control ensure fast and even solidification, preventing warping or bubbles.

- Equipment and Production Matching: Deran uses machines ranging from tabletop to fully automated injection molding machines, flexibly arranged according to batch size. Complex or two-color molding uses multiple injection heads and automated temperature systems for smooth color transitions and fine detailing.

- Precision Parameter Control: Experienced engineers precisely control temperature, pressure, injection speed, hold time, and cooling time. Deran has established a process database for quickly selecting optimal parameters for different materials and product shapes, enhancing consistency.

- Defect Prevention and Quality Stability: Through optimized mold venting, material drying, and precise injection control, Deran effectively prevents bubbles, short shots, and warping. A full-process quality monitoring system ensures every Jibbitz meets high standards from material intake to finished product shipment.

Color, Surface Treatment, and Customization

The color and surface treatment of Jibbitz charms are crucial for visual appeal and market competitiveness. Deran has extensive experience in color control, surface finishing, and customization to meet the needs of children’s products, gifts, and brand markets.

- Precise Color Control: Deran uses masterbatch mixing, two-color injection, and gradient techniques for high-precision color reproduction. All colors reference PANTONE standards to minimize batch-to-batch variation.

- Diverse Surface Treatments: Spraying, electroplating, UV coating, and matte finishing enhance texture and wear resistance. Special effects, such as metallic shine, transparency, or matte touch, can be added according to design needs.

- High-Precision Customization: Deran supports logo engraving, 3D cartoon shapes, holiday-themed designs, and functional structures (e.g., LED lights or rotating elements). By combining mold precision with injection molding, fine details are accurately rendered.

- Environmental Safety: All Deran Jibbitz products meet REACH, ROHS, EN71, and CPSIA certifications, using non-toxic, odorless, and skin-safe materials suitable for children and premium gift markets.

Choosing Deran Jibbitz: Assurance of High-Quality Injection Molding

Choosing a reliable manufacturer is key to ensuring Crocs shoe charms and Jibbitz quality. Deran, as a professional jibbitz manufacturer, offers significant advantages in injection molding, customization, and production management:

- Stable Supply Capability: Deran’s mature production system and extensive experience ensure timely delivery of large-volume orders.

- High Customization Capability: Supports complex shapes, two-color molding, and functional designs to meet client-specific needs.

- Extensive Collaboration Experience: Long-term partner for brands and cross-border e-commerce, with products exported to Europe, America, Japan, and Southeast Asia, gaining high reputation and repeat business.

- Brand Value Enhancement: Partnering with Deran provides clients with visually appealing, durable, eco-friendly, and highly customized Crocs charms and accessories, enhancing market competitiveness.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

With 20 years of professional experience, advanced injection molding technology, strict quality management, and eco-conscious production, Deran has become a trusted partner for Crocs charm customization. By working with Deran, brands, retailers, and e-commerce sellers gain high-quality jibbitz manufacturer and wholesale croc jibbitz products, along with efficient, professional customization services.

Whether it’s creative Jibbitz designs, functional shoe buckles, or full Crocs accessory solutions, Deran turns client ideas into reality, making every pair of Crocs shoes unique and full of personality.