Table of contents

Fundamentals of Croc Shoe Charms Injection Molding

Injection molding is a core process in manufacturing Crocs shoe charms, such as Jibbitz and decorative accessories. It involves injecting high-temperature molten plastic into molds, which then cools and solidifies into the desired shape. This process achieves high precision and allows for complex designs, ensuring consistency for every piece. It is the preferred method for croc shoe charms wholesale and wholesale shoe charms for crocs customers.

1. Common Materials and Properties

- EVA (Ethylene-Vinyl Acetate): Lightweight, flexible, and non-slip, suitable for children’s shoe charms. Density approximately 0.95 g/cm³, hardness 20-60 Shore A, with adjustable elasticity and feel.

- PVC (Polyvinyl Chloride): Low cost, highly wear-resistant, ideal for large-scale production.

- TPU (Thermoplastic Polyurethane): Combines flexibility and wear resistance, preferred for high-end custom charms.

2. Injection Molding Equipment Overview

- Types: Vertical and horizontal injection machines, selected based on product size and mold complexity.

- Clamping Force: Ranges from 50 to 500 tons, ensuring sufficient molding pressure.

- Temperature Control: Accurate to ±1°C to ensure uniform melting.

- Pressure Control: Ensures uniform injection pressure to prevent bubbles and warping.

3. Mold Design Key Points

- Cavity Number: Multi-cavity molds allow batch production and higher efficiency.

- Vent Design: Prevents trapped air, ensuring smooth surfaces.

- Cooling System: Ensures uniform cooling, improving production efficiency and reducing warping.

Injection Molding Steps and Tips

Material Preparation and Drying

Plastic pellets must be dried before molding to avoid bubbles. EVA is typically dried at 80°C for 2-3 hours, TPU at 90-100°C for 1-2 hours. Drying improves molding quality and extends mold life.

Mold Heating and Injection Parameter Settings

Mold temperature varies by material: EVA molds 60-80°C, TPU 90-110°C. Injection pressure and speed should match product thickness; too high causes flash, too low results in incomplete filling. Experienced operators often use staged injection: low pressure to fill, high pressure to pack, ensuring detail accuracy.

Cycle Time Optimization

Molding cycle includes injection, holding, cooling, and demolding. Optimizing cooling time can improve productivity; too short may cause shrinkage or warping. Small charms typically take 20-40 seconds, larger or complex designs up to 60 seconds. Proper production line timing enhances efficiency.

Common Defects and Solutions

- Bubbles: Usually from moisture or poor venting; solved by better drying or vent design.

- Warping/Distortion: Caused by uneven cooling or mold temperature differences; improved cooling design mitigates this.

- Shrinkage: Controlled by increasing holding time or slight mold adjustments.

Properly controlling injection parameters ensures precision and allows for diverse charm designs.

Croc Shoe Charms Spraying Process

Spraying is a key step in enhancing the surface aesthetics and functionality of Crocs shoe charms. It provides rich colors and metallic effects while improving wear and water resistance, which is highly valued by croc shoe charms wholesale and wholesale shoe charms for crocs customers.

1. Purpose of Spraying

- Aesthetics: Offers a variety of colors, metallic effects, and gloss to enhance visual appeal.

- Functionality: Increases wear resistance, water resistance, and adhesion, extending product life.

2. Common Spraying Materials and Features

- Acrylic Paint: Fast-drying, vivid colors, eco-friendly, suitable for batch production.

- PU Paint: Strong adhesion, high wear resistance, ideal for outdoor charms.

- Metallic Paint: Achieves silver, gold, or metallic effects, adding premium feel.

3. Spraying Equipment

- Includes pneumatic spray guns, high-pressure airless sprayers, or automated spraying lines, chosen based on charm size and production volume.

Spraying Tips and Quality Control

Surface Preparation

Clean and sand the charm surface to remove oil or burrs. A primer helps improve adhesion and prevents color penetration; acrylic primers are commonly used.

Layering and Drying Intervals

- Primer Layer: Thin and uniform, dries 5-10 minutes.

- Color Layers: 2-3 layers depending on design, each with 10-minute intervals for even drying.

- Top/Protective Layer: Increases wear resistance and gloss; post-drying can withstand over 5000 friction tests (Deran internal test, 2024).

Drying and Curing

Conventional oven drying at 60-80°C for 15-20 minutes; UV spraying allows 1-2 minute rapid curing, boosting productivity.

Common Issues and Solutions

- Runs/Drips: Reduce layer thickness or increase drying interval.

- Bubbling: Check solvent content and humidity.

- Color Inconsistency: Adjust spray angle and speed; apply multiple uniform layers.

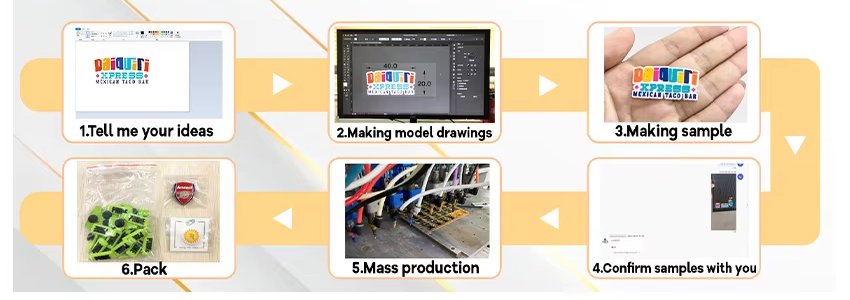

From Design to Finished Product

- Design Drawings and Digital Modeling: Designers use CAD or 3D modeling software to create charm shapes, with 3D printing for prototypes to quickly verify form and dimensions.

- Mold Making, Trial, and Adjustments: Mold production uses high-precision CNC or EDM to ensure detail accuracy. Trial molds identify issues like burrs or uneven wall thickness, adjusted before mass production.

- Integration of Injection Molding and Spraying: After molding, charms are sanded, cleaned, primed, and sprayed to achieve color and surface protection. Every step follows strict parameter control for consistency.

- Final Inspection and Packaging: Dimensions, color, surface defects, and adhesion are checked. Packaging uses anti-scratch materials to ensure safe transport.

Deran’s Craftsmanship Innovation and Expertise

Deran possesses distinct technical advantages in Crocs shoe charm production:

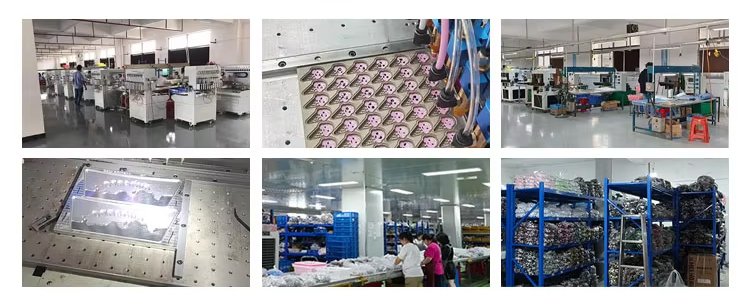

- Equipment and Process Upgrades: High-speed injection machines combined with precision spraying systems enable high-precision production of complex designs.

- Small-Batch Customization and Rapid Sampling: Supports diverse designs and limited editions, shortening design-to-product cycles to 10-15 days.

- Quality Control System: Every step, from raw material inspection, mold trials, injection molding to spraying, follows strict testing, including ±0.1mm dimensional tolerance and adhesion ≥ grade 1 (internal standard).

- Technical Experience: Deran’s team has over 20 years of experience, fully understanding material performance and process optimization.

These strengths make Deran a reliable partner for croc shoe charms wholesale and wholesale shoe charms for crocs, ensuring both visual appeal and durability for every charm.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Mastering injection molding and spraying is key to producing high-quality Crocs shoe charms. Proper control of materials, molds, equipment, and spraying parameters not only improves productivity but ensures beautiful, durable products.

For beginners or small-scale manufacturers, understanding these processes and applying them practically can significantly enhance competitiveness.

With extensive experience, advanced equipment, and a robust quality system, Deran is a trusted partner for croc shoe charms wholesale and wholesale shoe charms for crocs clients. Whether for mass production or custom designs, mastering injection and spraying techniques is the foundation of success.