Table of contents

Deran’s Unique Advantages: Why Choose Them

When selecting a crocs shoes manufacturer, Deran stands out as a top choice for brands and individuals seeking high-quality custom footwear. Founded in 2005 in Quanzhou, China, Deran has over 20 years of experience specializing in the production of wooden clogs, flip-flops, Gibbets slippers, and fur slippers. As a professional OEM/ODM manufacturer, Deran offers a complete one-stop service from design and sample production to mass manufacturing.

- Factory and Production Capacity: Deran operates four modern production lines with a monthly output of 400,000 pairs. This capacity ensures stable supply for both small trial orders and large-scale production. Located in a globally recognized slipper production hub, the factory benefits from abundant raw material resources, advanced equipment, and a skilled workforce, guaranteeing both efficiency and high quality.

- Extensive OEM/ODM Experience: Deran has long-term cooperation with overseas brands, providing OEM/ODM services that follow mature production processes and craftsmanship. Their fast prototyping and iterative design capabilities help clients launch limited editions, seasonal products, and brand collaboration items quickly and reliably.

- Eco-Friendly Materials and International Standards: Deran uses environmentally friendly materials such as EVA, natural rubber, linen, and bamboo fiber blends. These materials comply with international standards including REACH, ROHS, OEKO-TEX, and TUV. They are not only safe and sustainable but also ensure comfort, durability, and breathability for global markets.

- Flexible Minimum Order Quantities: Deran offers flexible minimum order quantities: custom Crocs shoes from 200 pairs, custom slippers from 50 pairs, custom flip-flops from 1,500 pairs, and custom Jibukus from 500 pieces. This significantly lowers the barrier to collaboration for small and medium-sized enterprises, providing convenience for diverse client groups.

Detailed Customization Process for Crocs Shoes

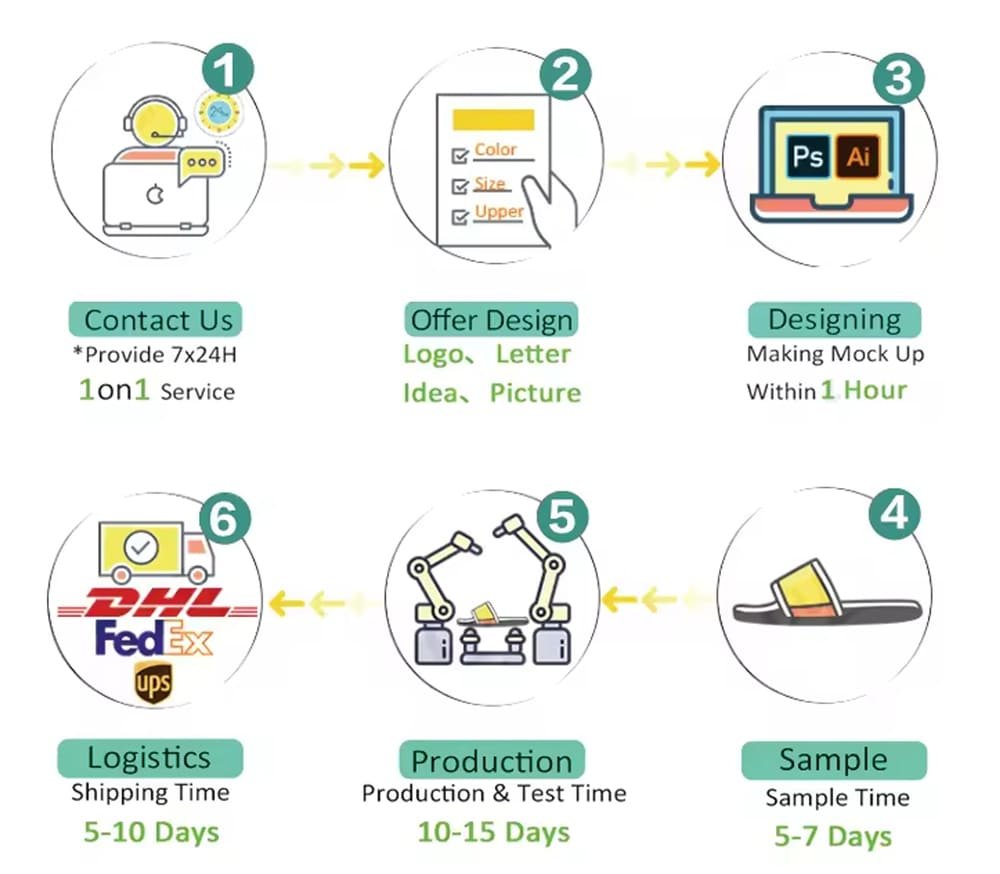

Deran provides a highly professional and standardized workflow for custom croc shoes, ensuring that every pair meets client requirements.

- Design and Sampling Stage: Clients can submit their design concepts, logos, creative images, or text. Deran’s design team can generate a digital model within one hour and produce initial samples for review. The sample production period is typically 5-7 days, minimizing errors before mass production.

- Mold Production and Optimization: Deran uses rapid mold-making technology to complete shoe mold design and adjustments quickly. Through repeated testing and iteration, they ensure the final shoe is comfortable, durable, and matches the design specifications.

- Material Selection and Blending: Deran’s slippers primarily utilise materials such as EVA, natural rubber, and a blend of linen and bamboo fibres. EVA offers lightweight softness and exceptional abrasion resistance; natural rubber provides excellent elasticity and high durability; while the linen-bamboo fibre blend is not only environmentally friendly but also delivers superior breathability and comfort. These materials undergo rigorous selection and precise formulation to ensure the finished footwear’s quality and comfort.

- Mass Production and Quality Control: During mass production, Deran implements rigorous QC procedures including hardness testing, compression recovery tests, temperature resistance testing, and wear-resistance evaluations. An issue tracking system ensures that all batches meet international standards.

- Fast Production and Delivery: Deran can produce a single batch of slippers in as fast as 12-24 hours. Official order production and testing typically take 10-15 days, and logistics shipping takes approximately 5-10 days, enabling clients to receive products quickly.

Quality Control and Professional Tools

Deran’s quality control system is a key factor in becoming a top crocs shoes manufacturer.

- Advanced Testing Equipment: The factory is equipped with hardness testers, compression recovery testing machines, temperature resistance devices, and other professional instruments to ensure soles and footwear performance meet design standards.

- International Certifications and Management System: Deran strictly follows ISO and international environmental standards, integrating quality management and sustainability throughout production to guarantee products meet global market requirements.

- Issue Tracking and Feedback Mechanism: Every batch undergoes a comprehensive issue tracking process. Customer feedback, production anomalies, and quality issues are recorded and analyzed immediately, with corrective actions applied to ensure consistent quality in subsequent orders.

Market Applications and Success Stories of Deran Custom Shoes

Deran’s custom shoes are widely used globally, demonstrating professional capabilities and extensive experience.

- International Client Cooperation: Deran provides long-term OEM/ODM services for overseas brands, including brand authorization and limited edition custom orders. Clients can test small batches of samples to quickly validate design and material choices, reducing risk.

- Trends in Personalized Design: The demand for personalized footwear is growing, covering school, corporate, event, and collaboration shoes. Deran’s flexible customization process and rapid response capabilities help clients create differentiated products, enhancing market competitiveness.

- Market Data Reference: Slippers account for approximately 15%-30% of the global footwear market. Among them, customized slippers and custom croc shoes continue to grow steadily, reflecting the strong market potential of personalized and eco-friendly footwear. Deran leverages its mature production techniques, eco-friendly materials, and rich experience to capture these market opportunities and deliver value to clients.

Practical Tips for Choosing Deran as Your Crocs Shoes Manufacturer

Selecting the right crocs shoes manufacturer involves several practical steps:

Communicate Design Requirements

- Provide design files, samples, or reference images to ensure clear instructions

- Use Deran’s 24/7 one-on-one online service to provide fast feedback on revisions

Manage Production Timeline and Costs

- Sample production: 5-7 days

- Mass production and testing: 10-15 days

- Shipping: 5-10 days

Proper planning of production and logistics helps control costs and delivery times.

Transition from Small-Batch Testing to Mass Production

- Conduct small-batch sample testing first to verify design, materials, and sizing

- Optimize based on feedback before mass production to reduce risk

Common Issues and Solutions

- Color deviation: confirm Pantone colors and check sample accuracy

- Size inconsistency: use professional lasts and size measurement tools

- Production delays: schedule orders in advance and maintain communication with the production line

Payment and Sample Policy

- Supports T/T, L/C, D/A, and other payment methods, negotiable for convenience

- Sample fees are refundable upon placing a formal order; shipping costs borne by clients

- Sample production typically completed within one week, official orders produced within 30 days after deposit

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

As a custom croc shoes and slipper OEM/ODM manufacturer with over 20 years of experience, Deran combines advanced production equipment, rigorous quality control, eco-friendly materials, and flexible customization capabilities. It is a trusted partner for global clients seeking professional, efficient, and reliable footwear manufacturing. Choosing Deran ensures not only high-quality products but also a long-term, dependable partnership, making every pair of Crocs and slippers comfortable, durable, and personalized.