Table of contents

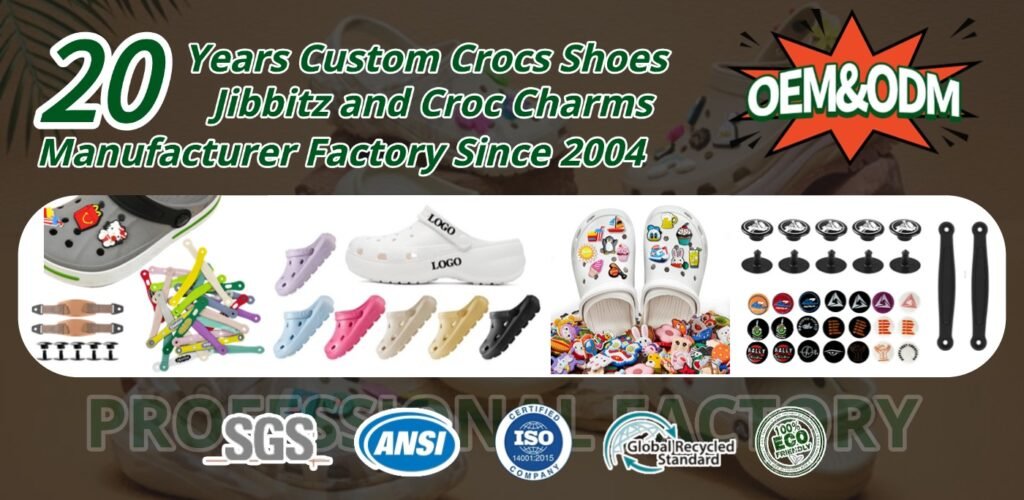

Who is Deran, the custom Crocs factory?

Deran is a professional footwear manufacturer specializing in the R&D, manufacturing, and customized production of Crocs and Birken-style shoes. It has long served international brands, cross-border e-commerce brands, retailers, gift companies, and channel distributors.

Unlike general footwear factories, Deran has a very clear strategic positioning:

👉 Focusing on injection-molded shoes and functional casual shoes, building a highly consistent, stable, and replicable custom manufacturing system.

Deran’s Core Factory Strength Structure

From a manufacturing perspective, Deran possesses the following stable production foundations:

- Professional injection molding production lines

- Independent mold development and maintenance team

- Experimental system for shoe materials such as EVA, PVC, and TPR

- Complete shoe assembly, packaging, and quality inspection processes

- Specialized Crocs and Birkenstock shoe product lines

Compared to general shoe factories that “make all kinds of shoes,” Deran is more like:

👉 A specialized factory that deeply optimizes its manufacturing system around the Crocs structural model

This vertical focus results in:

- Higher mold compatibility

- Faster mold opening efficiency

- Better sizing stability

- Stronger consistency in batch delivery

Deran’s Client Structure

Deran’s clients primarily include:

- International casual shoe brands

- E-commerce private domain brands

- Corporate gift purchasers

- Chain retail channels

- Medical and work shoe customization brands

- Outdoor and travel product brands

This means that Deran is not just an “OEM manufacturer,” but a manufacturing partner with cross-market demand understanding and product structure adaptation experience.

Introduction and Advantages of Crocs Factories in China

If you’re looking for Crocs OEM or custom crocs shoes manufacturer in China, you should first understand their distribution and core capabilities.

Concentrated Factory Areas

Guangdong (Foshan, Dongguan, Huizhou): Known for its light manufacturing and footwear industries, these factories offer advanced equipment and high-precision molds, making them suitable for custom and mid- to high-end Crocs products.

Fujian (Jinjiang, Quanzhou): Fujian is a major base for sports and casual shoes in China, hosting numerous OEM factories for international brands, making it ideal for large-volume Crocs orders.

Zhejiang (Wenzhou, Taizhou): Specializing in shoe accessories and small-batch OEM production, they are particularly well-suited for customers requiring diverse shoe accessories or small, personalized orders.

Core Advantages of Chinese Factories

Complete production equipment: including fully automatic foam molding machines, precision CNC mold processing centers, and complete sole and upper mold production lines.

Efficient Sample Development: Samples are typically completed within 7-15 days, meeting the needs of cross-border e-commerce or testing new models.

Flexible Customization: Supports comprehensive customization of shoe color, sole texture, accessories, packaging, and more.

Strict Quality Control: Our established factory holds ISO9001 and BSCI certifications, and some also meet REACH and OEKO-TEX environmental standards, meeting European and American market requirements.

Deran’s Professional Crocs Customization Factory Capabilities

Deran is a long-standing manufacturer of Crocs shoes and shoe accessories for overseas customers, offering the following advantages:

- Full-Process OEM/ODM Customization: One-stop service from design, mold creation, production, and shipping.

- We have extensive experience in producing EVA, TPU, and Croslite foam materials, ensuring comfortable and lightweight shoes.

- Our factory is equipped with comprehensive mold manufacturing capabilities, enabling rapid development and consistent batch consistency.

- Our products are exported to North America, Europe, and Southeast Asia, meeting the import standards of multiple countries.

If buyers want to quickly develop new Crocs models or customize unique footwear accessories, Chinese factories, especially specialized manufacturers like Deran, are the best option.

Deran’s Core Advantages in Custom Crocs: Materials, Craftsmanship, Design, and Delivery Systems

A truly professional Crocs customization factory doesn’t just “change colors and slap on logos.” It needs to establish a complete system capability in material selection, structural design, mold engineering, production processes, quality systems, and supply chain collaboration.

Deran’s core advantages are reflected in the following five aspects:

Material System Advantage: A Balanced Design of Comfort, Environmental Friendliness, and Durability

The wearing experience of Crocs shoes depends over 70% on the material system, not the appearance.

Deran primarily utilizes the following material systems in its Crocs products:

- EVA (Ethylene-Vinyl Acetate Copolymer)

- PVC Injection Molding Material

- TPR Flexible Rubber Composite System

- Environmentally Friendly and Recyclable Injection Molding Material Solutions

According to American Chemistry Council (ACC) material performance data, EVA material offers the following advantages:

- Low density → Lighter shoe body

- High resilience → Less prone to collapse after prolonged wear

- Strong water resistance → Suitable for various wearing scenarios

- Easy to dye → Supports high-saturation color customization

Deran’s material engineering team recommends different material combinations based on the customer’s usage scenario:

- Everyday slippers → Soft EVA high-resilience formula

- Medical work shoes → High-support EVA + anti-slip outsole structure

- Outdoor beach shoes → Water-resistant PVC + anti-aging stabilizer system

- Promotional gift shoes → Cost-effective lightweight material solutions

This differentiated material design capability enables Deran to truly achieve:

👉 It’s not simply about making shoes; it’s about product engineering design for specific usage scenarios.

Advantages in mold and structural design: A combination of comfort and production stability.

Crocs shoes are typical mold-driven products. Mold quality directly determines:

- Whether the shoe proportions are harmonious;

- Whether the sizing is stable;

- Whether the finished product yield is controllable;

- Whether batch replication is consistent.

Deran possesses the following capabilities in its mold system:

- Internal mold engineering team participates in the product structure design phase;

- Support for private mold development and shared mold customization;

- A comprehensive mold lifespan and stability testing system;

- Support for simultaneous structural optimization across multiple sizes.

Advantages in color and appearance customization: System control from Pantone to batch consistency.

In Crocs customization projects, color and appearance are often among the most important elements for the brand.

However, many buyers find the following in practice:

- Sample colors do not match mass-produced colors.

- Significant color differences exist between different batches.

- Injection molding color saturation cannot be stably replicated.

- Dark colors tend to appear grayish, and light colors are prone to showing through.

Deran employs the following system for color control:

- Supports Pantone, RAL, and customer sample color matching.

- Performs small-sample color testing before injection molding.

- Establishes a material batch color database.

- Performs color difference meter testing before each batch production.

In batch Crocs projects, Deran typically controls color difference within the standard range of ΔE ≤ 1.2, ensuring visual consistency across batches.

Furthermore, in terms of appearance customization, Deran supports:

- Implanted embossed logo on the upper.

- Customized hollowed-out structure on the upper.

- Patterned heel design.

- Customized anti-slip outsole texture.

- Complete brand customization for shoe boxes and packaging.

This allows customers to build a complete brand product identification system, not just “recolored shoes.”

Production and Delivery System Advantages: Stable Scale Output Capability

Crocs shoes are standardized, highly repetitive products. The real challenge isn’t simply “making” them, but rather:

👉 Maintaining a consistently high standard of consistency while consistently producing over 10,000, 50,000, or even 100,000 pairs of products.

Deran has built the following capability structure into its delivery system:

- Multi-line parallel injection molding production scheduling system

- Standard process parameter database

- Multi-batch quality consistency sampling inspection system

- Size structure ratio control system

- Flexible capacity scheduling mechanism

In actual projects, Deran can achieve:

- Small-batch trial orders → Rapid delivery of 500–2000 pairs

- Medium-batch ramp-up → Stable replication of 5000–20000 pairs

- Large-scale orders → Support for continuous batch shipments

This continuous capability from prototyping to mass production is something many small and medium-sized shoe factories struggle to achieve.

Customization Process and Considerations at Crocs Factories in China

If you plan to customize Crocs shoes in China, it’s crucial to understand the typical process and considerations.

Customization Process

- Design Confirmation: Provide a design drawing or reference sample to confirm color, size, and shoe trim requirements.

- Mold Opening and Prototyping: The factory creates the mold and foams the sample, typically within 7-15 days.

- Sample Confirmation: After the customer confirms the sample, the contract is signed and mass production begins. Mass Production: Depending on the order quantity, typically 15-45 days.

- Quality Inspection and Packaging: A comprehensive quality inspection is conducted before shipment, and branded packaging is provided upon request.

- Shipping: Sea, air, or express shipping options are available, and some factories offer one-stop export services.

Customization Considerations

- Material Selection: The ratio of EVA, TPU, and Croslite directly impacts comfort and weight.

- Color Stability: Strict color variation must be controlled when mixing dark and light colors.

- Mold Precision: This directly impacts the sole pattern, slip resistance, and aesthetics.

- Delivery Time and Planning: Placing orders 2-3 months in advance is more reliable and helps avoid production constraints during peak seasons.

Tips for Managing Delivery Time and Costs

- Placing orders in batches can reduce material procurement costs;

- Using proven formulas recommended by the factory can speed up production;

- Maintaining timely communication with the factory can avoid design modifications and delays.

Frequently Asked Questions (FAQs)

Q1: What is the difference between official Crocs shoes and Chinese OEM shoes?

A: Official Crocs shoes are typically mass-produced in Vietnam or Indonesia, while Chinese OEM shoes are more suitable for custom designs. The materials and craftsmanship can be similar or identical, but the ability to print the Crocs logo requires brand authorization.

Q2: What is the minimum order quantity for custom Crocs?

A: Most Chinese factories have an MOQ of 500-1000 pairs, but smaller factories may accept trial orders of 200-300 pairs, which is suitable for e-commerce brands or small wholesalers.

Q3: How can you ensure consistent quality during mass production?

A: We recommend choosing an ISO/BSCI-certified factory and conducting a small trial run, with a detailed quality agreement signed.

Q4: What is the typical lead time for custom Crocs?

A: From mold creation and proofing to full production, it typically takes 30-60 days, and can be faster during off-seasons.

Q5: Can the Chinese Crocs factory offer overseas shipping?

A: Established factories typically offer FOB, CIF, or DDP services, and some can even arrange overseas warehouse delivery.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

China remains an ideal choice for Crocs shoe customization and OEM production due to:

- A comprehensive supply chain and strong mold and material capabilities;

- Flexible customization services that can accommodate small batches and diverse needs;

- Extensive export experience and adherence to international quality standards.

For buyers, choosing a professional Crocs customization factory like Deran can significantly reduce development complexity and ensure consistent delivery and quality. Whether you’re a cross-border e-commerce company, a small brand, or a wholesale distributor, Chinese factories offer one-stop solutions from design and mold making to mass production.

If you’re looking for a reliable custom crocs shoes factory, Chinese OEM factories are undoubtedly the most trustworthy partners.