Table of contents

- Who is Deran? Learn more about the background and strength of Crocs shoe customization manufacturers

- Analysis of the whole process of Deran customized Crocs: from creativity to finished products

- Key links and practical suggestions for customizing Crocs

- Common customer needs and Deran’s solutions: Successful case sharing

- How to start your Crocs customization project with Deran? Cooperation process and skills

Who is Deran? Learn more about the background and strength of Crocs shoe customization manufacturers

Deran is a professional crocs shoes manufacturer focusing on the research and development, design and manufacturing of Crocs hole shoes and shoe accessories. It has long served multiple markets such as Europe, Southeast Asia, and North America, and enjoys a high reputation in the industry for its high-quality products and flexible customization services.

Deran’s advantages are reflected in many aspects:

Powerful production system: The company has a complete injection molding production line and mold manufacturing factory, supporting EVA, TPR, TPU and other materials, with a monthly production capacity of more than 500,000 pairs, and can quickly respond to customers’ small and medium batches or even large batches of customization needs.

Experienced design team: Deran has a dedicated shoe structure designer and appearance creative design team, which can develop a complete 3D shoe body structure model and Jibbitz accessories design plan based on the customer’s preliminary concept or simple draft.

Integrated manufacturing capability for accessories: In addition to the shoe body, Deran also has the capability to manufacture and inject molds for Jibbitz accessories, supporting customized processes such as PVC soft glue, multi-color drop molding, and thermal transfer, and can provide customers with one-stop service.

Rigorous quality control process: All products have undergone multiple proofing tests and mass production QC, including compression test, anti-slip coefficient test, heat resistance test, etc., in compliance with international standards such as REACH, ROHS, and CPSIA.

Complete certifications and export compliance: The factory has passed the BSCI social responsibility audit, ISO quality system certification, and has been approved by international brands such as Walmart, Disney, and Target. It is the designated Crocs shoe supplier for many brands.

Analysis of the whole process of Deran customized Crocs: from creativity to finished products

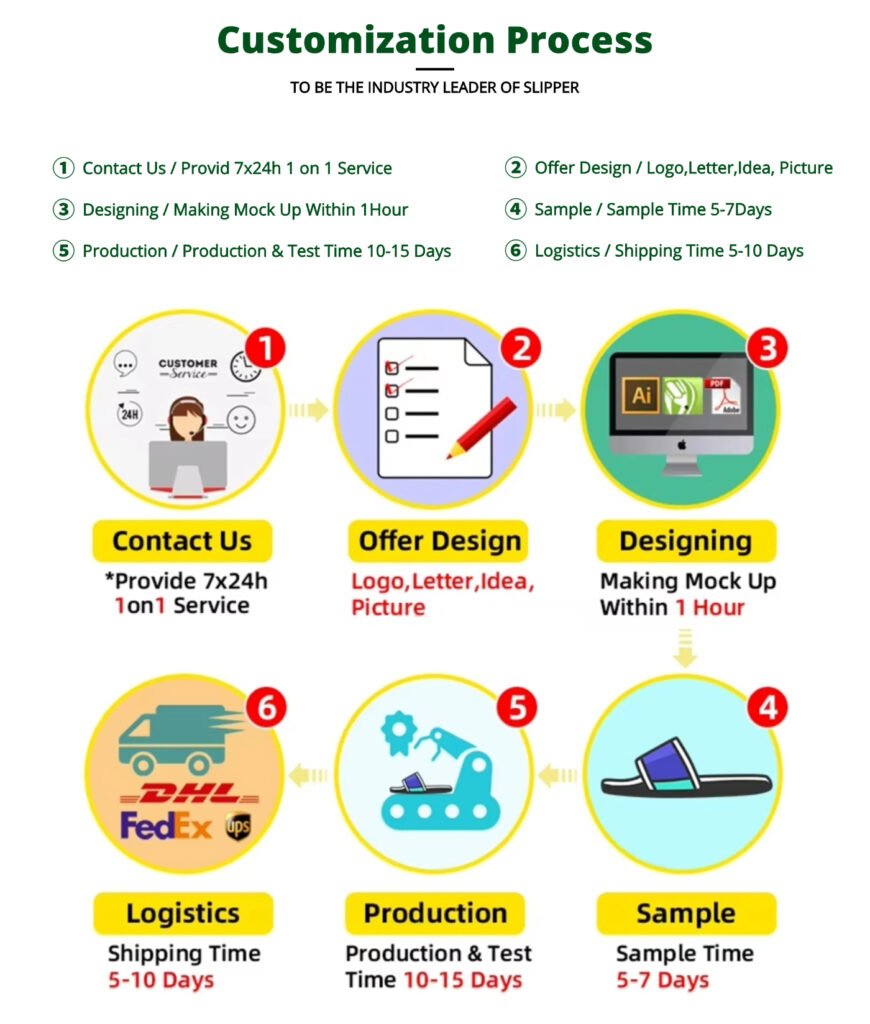

Many customers may feel confused when they customize Crocs for the first time. Deran has established a complete customer service process, which is visualized and traceable from creativity to shipment, ensuring that every link is completed efficiently and accurately.

Step 1: Creative communication and confirmation of functional requirements

Customers can provide initial ideas such as logo, IP elements, color matching, functional requirements, etc. Deran sales team and product managers will communicate with customers one-on-one to confirm the target population (children, adults, medical care, home, etc.), usage scenarios (beach, hospital, supermarket, etc.), as well as shoe type, size range, price target and other information.

Step 2: Modeling design and rendering

The design team uses professional software such as Rhino 3D, SolidWorks, Adobe Illustrator, etc. to draw 3D modeling of the shoe body and upper structure diagram, and renders the overall picture with shoe accessories, so that customers can see the final effect of the product in advance.

Step 3: Material selection and function setting

Customers can choose materials such as EVA (light and soft), TPR (high elasticity and wear resistance), TPU (transparent or high impact resistance), etc., and can also request functional additions: antibacterial agent, deodorant, fluorescent powder, luminous powder, etc. The color supports PANTONE number customization.

Step 4: Mold development and proofing

After confirming the design plan, the factory will open various injection molds for soles, uppers, shoe decorations, etc., and the general mold opening cycle is 7-10 days. After completion, a small sample will be made and sent to the customer for confirmation.

Step 5: Trial production and mass production

The trial production stage is usually 100,500 pairs. After confirming that the samples are qualified, the formal mass production will begin. The production cycle is about 1525 days, and multiple quality inspections and color verifications will be carried out during the process.

Step 6: Packaging and shipment

Deran supports a variety of packaging methods (OPP bags, paper boxes, customized color boxes, etc.), and can be labeled according to the UPC or EAN code provided by the customer, and finally arranged for sea, air or express delivery.

Key links and practical suggestions for customizing Crocs

Design draft preparation skills

It is recommended to use AI or CorelDRAW to draw the upper logo and shoe decoration elements. The pattern needs to be converted into curves, and avoid using overly complex gradients or high-frequency textures.

Color matching suggestions

If targeting the children’s market, it is recommended to use macaron colors, such as light blue, mint green, and pink. The adult market is suitable for classic black, gray, military green, navy blue and other main colors, with bright shoe accessories as embellishments.

Logo and accessories customization

Deran supports multiple methods such as drop molding, thermal transfer, laser engraving, and silk screen printing. Accessories can be in the form of magnetic suction, buckles, perforated pendants, etc., taking into account practicality and personality.

Shoe size reference table

Market positioning needs to be clarified, such as European size 36-45 is suitable for the European market, and US size 5-11 is suitable for the North American market. The foot shapes of users in different countries vary greatly. It is recommended to refer to historical sales data for optimization.

Material selection and function development suggestions

If the target customers are medical and nursing groups, it is recommended to use antibacterial EVA materials; if it is for summer beach use, it is recommended to use waterproof TPU materials and strengthen the air permeability design; luminous and luminous elements are suitable for children to use at night.

Common customer needs and Deran’s solutions: Successful case sharing

Customer A: Brand co-branded IP series

A French fashion brand hopes to apply its own cartoon IP image to Crocs shoes. Deran developed a dedicated upper mold for it and made co-branded shoe accessories. Finally, 3 colors were launched, and the monthly sales exceeded 20,000 pairs.

Customer B: Medical care industry

A Japanese medical brand commissioned the development of an easy-to-clean, non-slip, and antibacterial hospital-specific Crocs. Deran uses a closed toe structure design and a thickened non-slip texture on the sole. Customer satisfaction is extremely high, and it has now become its long-term cooperative factory.

Customer C: Children’s market

Australian customers want to launch a safe, non-toxic, and colorful children’s Crocs. Deran uses food-grade EVA materials and configures luminous Jibbitz on each pair of shoes, successfully opening up school and family procurement channels.

Customer D: Festival event quick order

A large event company hopes to launch a limited edition “Year of the Dragon Crocs” on the eve of the Spring Festival, and time is tight. Deran quickly modified the existing mold and completed the proofing + 5,000 pairs of bulk delivery in just 18 days.

How to start your Crocs customization project with Deran? Cooperation process and skills

Communicate design and submit drafts: It is recommended to provide basic information such as sketches, brand LOGO, shoe size requirements, etc.

Sample production and proofing confirmation: After confirming the design plan, enter the sample proofing, during which you can apply for material samples and color chips for comparison.

Production scheduling and contract signing: Arrange the production schedule according to the customer’s delivery date and sign a formal order.

Factory follow-up and quality inspection nodes: Deran has professional customer follow-up personnel, and real-time reports throughout the process.

Delivery and after-sales: Support third-party inspection before shipment to ensure the stability of the quality of each batch of goods.

Tips:

- Development arrangements 45 days in advance can get sufficient time for proofing and molding.

- Want to shorten the delivery time? Choose Deran’s “fast mold” service, and the proofing can be completed in 7 days.

- Want to control the budget? Try to use standard molds, and focus on color and logo customization to effectively save costs.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

As the global craze for Crocs continues to heat up, choosing a professional and flexible manufacturer is the key to achieving differentiated competition and brand value. With 20 years of experience in Crocs manufacturing, Deran has a full controllable process from design creativity to mass production, providing successful product implementation solutions for countless brands and start-ups.

In the future, Crocs still has huge room for innovation. Deran will continue to upgrade its technology, expand environmentally friendly materials and functional modules, and help more customers custom made crocs shoes that are both good-looking and comfortable to wear. If you also have creativity, welcome to start your own customization journey with Deran.