Table of contents

Deran’s Professional Advantages and Experience

- Extensive Industry Experience: Since its establishment in 2005, Quanzhou Deran Slipper Factory has accumulated 20 years of experience in footwear and accessory production. The company has long provided customization services to clients in Europe, America, Japan, and Southeast Asia, with a high repurchase rate, demonstrating its reliability and stability in the international market.

- Advanced Production Facilities and Capacity: The factory covers approximately 4,000 square meters and is equipped with 4 fully automated production lines, with a monthly output of 400,000 pairs of slippers and 1 million Crocs charms. This production capacity can meet both small-batch custom orders and large-scale wholesale croc jibbitz orders, ensuring flexibility for different client needs.

- Professional Molding and Rapid Sample Development: Deran has an independent mold workshop capable of quickly developing new molds and prototypes, with sample cycles as fast as 7–10 days. The company provides full-process support from concept sketches to 3D printed prototypes to mass production, greatly improving new product iteration and market launch efficiency.

- International Certifications and Quality Assurance: Products have passed international certifications such as REACH, ROHS, EN71, and CPSIA, ensuring they are non-toxic, odorless, and skin-friendly, especially suitable for children’s shoes and gift markets. ISO 9001 quality management certification further guarantees standardized production processes and product consistency, enhancing client trust.

- Professional Team and Technical Expertise: The engineering team has over 10 years of experience in footwear accessory design, capable of customizing functionality and structure according to client needs, balancing aesthetics and practicality. The design team is proficient in CAD and 3D modeling tools and integrates color management systems to achieve high-precision customization that meets brand personalization requirements.

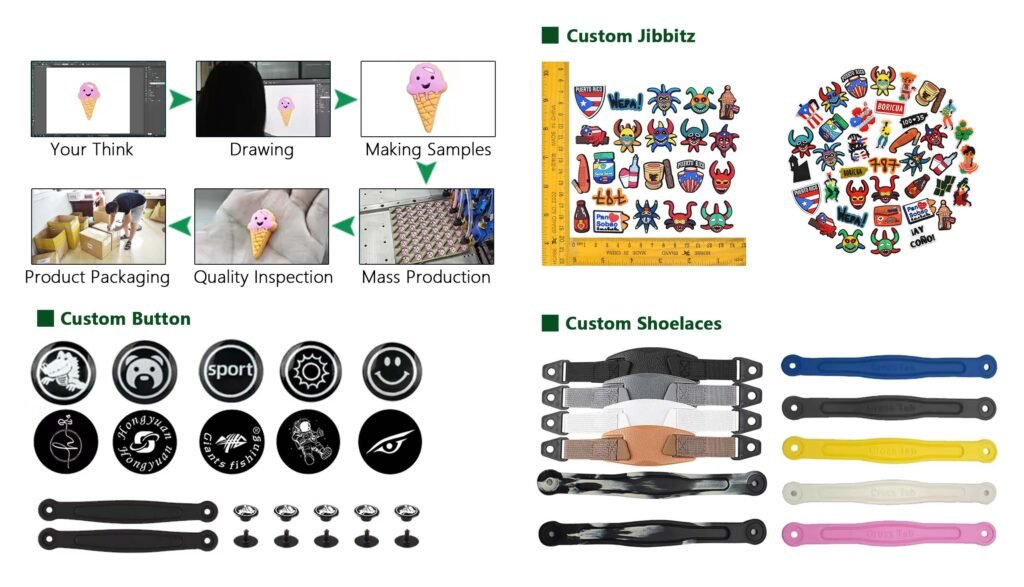

Design and Development Process for Custom Jibbitz

- Concept and Design Stage: Clients can provide sketches, images, or creative descriptions. Deran’s design team uses CAD software and 3D modeling tools to turn ideas into precise digital models. Digital models allow pre-verification of dimensions, proportions, and structures, reducing revisions and improving efficiency.

- Sample Production: Based on confirmed digital models, prototypes are produced using 3D printing and mold-making techniques. Samples can verify shape, dimensions, tactile feel, and allow adjustments to ensure consistency during mass production.

- Client Communication and Feedback: High-efficiency communication is maintained during the design and sampling stages. Designers provide professional suggestions on materials, color matching, structural optimization, and durability. The timely feedback mechanism ensures design feasibility and product usability.

- Cost and Process Optimization: During the design stage, Deran evaluates production processes, material costs, and mold efficiency to provide feasible solutions for reducing manufacturing costs while maintaining quality and functionality.

Through this process, Deran can quickly and accurately transform client ideas into mass-producible Jibbitz, meeting the personalized needs of various markets and consumer groups.

Core Capabilities of Deran in Jibbitz Customization

- Wide Range of Jibbitz Customization

Deran offers comprehensive customization services for Jibbitz charms:- Design Flexibility: Supports 2D and 3D craftsmanship, including cartoon characters, animals, logos, holiday themes, and co-branded designs.

- Material Options: Eco-friendly TPR, PVC, silicone, PP, and TPU materials are available, ensuring durability and safety for children and adults.

- Colors and Patterns: Colors can be customized according to Pantone standards. Complex patterns are supported via gradient, inkjet printing, or stamping techniques.

- Functional Decorations: Optional features such as LED lights or rotating mechanisms can be integrated into Jibbitz designs.

- Supported Business Models

Deran provides both OEM and ODM services specifically for Jibbitz:- OEM: Clients supply designs, Deran handles production, quality control, and delivery.

- ODM: Clients provide concepts, Deran offers design, prototyping, and full production services for a one-stop solution.

- Advanced Production Technology

- CNC mold precision ensures consistent size and structure for all Jibbitz charms.

- 3D printing allows rapid prototype verification to shorten development cycles.

- Automated inkjet and pad printing techniques enable intricate patterns and personalized decorations.

- Production Capacity and Delivery

Multiple automated lines support the mass production of Jibbitz, with flexible scheduling for both large and small batches. This ensures timely delivery while maintaining high-quality standards for wholesale croc jibbitz orders.

Deran Quality Control and Safety Standards

- Comprehensive Quality Control

Deran has established a multi-step quality control process specifically for Jibbitz and Crocs charms to ensure every product meets high standards:- Raw Material Testing: All materials and dyes used for Jibbitz and charms are tested for chemical and physical properties and comply with REACH and ROHS international environmental standards.

- Semi-Finished Product Inspection: Sampling during mold injection, inkjet printing, and assembly ensures charm dimensions, colors, patterns, and structures match design specifications.

- Finished Product Testing: Each batch of Jibbitz and charms undergoes pull, abrasion, bending, and colorfastness tests to ensure durability, shape retention, and color stability during everyday use.

- Compliance with International Standards

Deran products meet international certifications such as REACH, ROHS, EN71, and CPSIA, suitable for European, North American, and global markets. The factory can provide inspection reports and eco-material certificates upon client request, meeting the safety requirements of high-end children’s shoes, gifts, and e-commerce markets. - Comfort and Durability Assurance

Deran has developed a unique formula optimizing foam density, sole curvature, and weight distribution to ensure long-term comfort. Shoe buckles and Jibbitz decorations undergo repeated testing to guarantee secure, durable performance for both children and adults. - Logistics and Compliance Support

With extensive international export experience, Deran provides sea, air, and express shipping options. The team is familiar with customs and clearance procedures in various countries, helping clients reduce shipping risks and ensure timely delivery of customized products worldwide. - Continuous Improvement and Traceability

Detailed production, testing, and shipment records are maintained for every batch, ensuring full traceability. Through continuous process optimization, testing method improvements, and staff training, Deran consistently enhances product quality and client satisfaction, providing stable and reliable supply for long-term partners.

| OEM&ODM Factory | Email: sarah@clogsslipper.com | Whatapp: +8613960916317 |

Quanzhou Deran Slipper Factory (Deran), with 20 years of rich experience, mature design processes, core customization capabilities, and strict quality control systems, has become a trusted global partner for Crocs charms and Jibbitz manufacturer services. The company offers both small-batch rapid prototyping and large-scale wholesale croc jibbitz production.

Using eco-friendly materials, advanced production technology, precise color management, and high-efficiency capacity, Deran transforms client ideas into high-quality, safe, and personalized charms.

Whether for brand clients, e-commerce sellers, or gift companies, Deran provides a one-stop solution from design and prototyping to mass production, turning ordinary Crocs shoes into personalized, story-filled fashion items. Choosing Deran means choosing professional, innovative, and efficient customization services.